Combined and multi-task water turbine runner on-site processing factory design method

A design method and processing plant technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of complex processing procedures, increased pre-engineering investment, and high processing accuracy requirements, and achieve the effect of saving engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

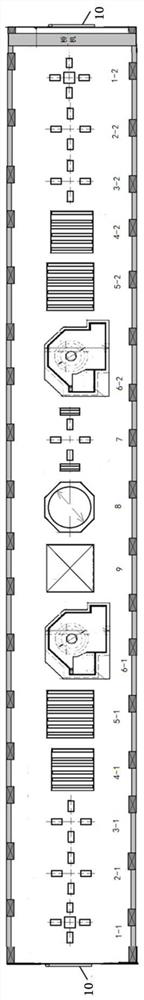

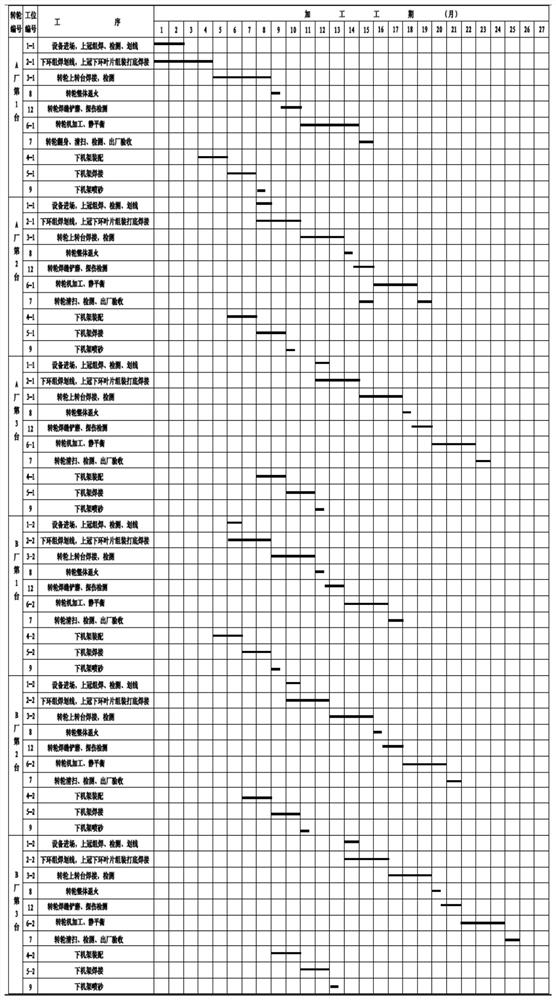

[0040] Such as Figure 1-3As shown, a joint, multi-task water turbine runner field processing plant design method of the present invention is special in that only one runner field processing plant can satisfy two or more different runners at the same time. And the on-site processing progress of two types of multiple sets of heavy parts. The technical scheme of the present invention is: a kind of joint, multi-task water turbine runner on-site processing plant station, procedure and the design method of auxiliary equipment, facility, it is characterized in that, comprises the following steps:

[0041] Step 1: Combined, multitasking wheel on-site processing plant number of stations

[0042] Based on the independent wheel processing plant, the repetitive stations with low utilization rate are simplified. n (n = 2, 3, 4, 5...) unit manufacturers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com