Device and method for casting and compounding titanium alloy and titanium-aluminum alloy

A technology of titanium-aluminum alloy and titanium alloy, which is applied in the field of devices for improving the performance of titanium-aluminum alloys, and in the field of devices for improving the performance of titanium-aluminum alloys by melting and casting titanium alloys and titanium-aluminum alloys. It can solve the problems of poor room temperature performance and achieve good plasticity. The effect of high strength and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

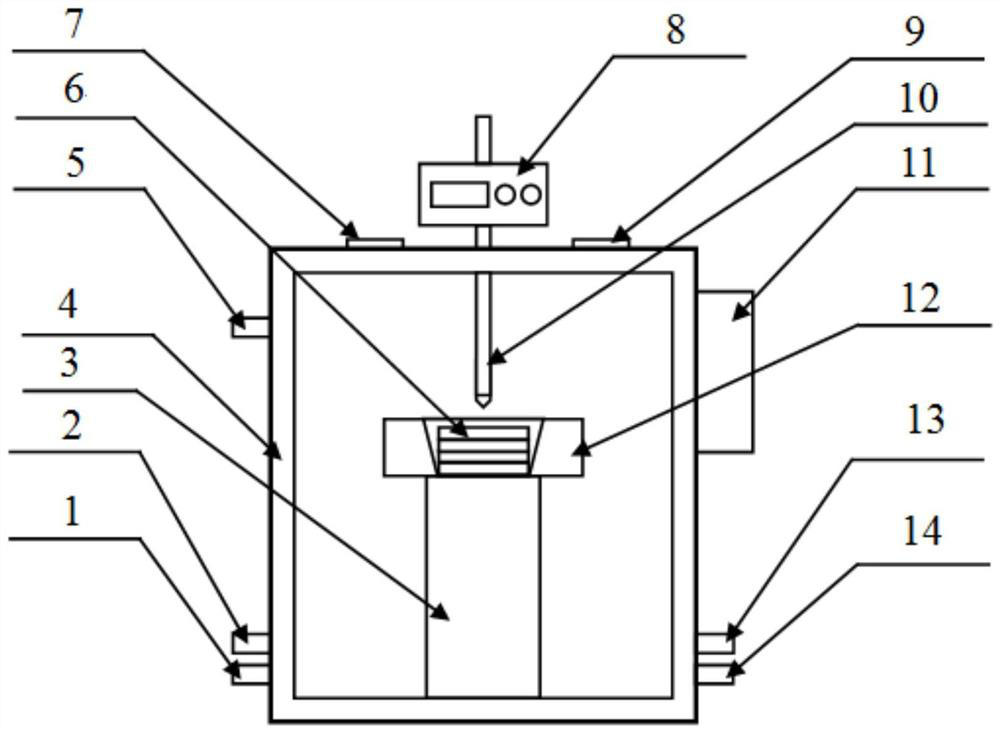

[0025] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a furnace body 4; also includes a water-cooled support 3, a water-cooled copper crucible 12, a material 6, a non-consumable tungsten electrode 10, an automatic control lifting device 8, a turning spoon 9 and a vacuum system 11 , the water-cooled support 3 is installed in the furnace body 4, the water-cooled copper crucible 12 is installed on the upper end surface of the water-cooled support 3, the material 6 is placed in the water-cooled copper crucible 12, and the automatic control lifting device 8 is installed on the outer upper part of the furnace body 4. The tungsten-consumable electrode 10 is vertically inserted into the furnace body 4 and extends to the top of the material 6. The upper part of the non-consumable tungsten electrode 10 is installed on the automatic control lifting device 8 and realizes lifting under the control of the automatic control lifting device...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 Describe this embodiment, present embodiment also comprises pressure gauge 5, inlet valve 1 and outlet valve 2, inlet valve 1 and outlet valve 2 are installed in the bottom of furnace body 4, and pressure gauge 5 is installed in the top of furnace body 4. In this way, the inlet valve 1 and the outlet valve 2 are located at the bottom of the furnace body. In order to protect the argon gas, the furnace body can be better filled with argon gas, and the purity of the argon gas fed into the inlet valve 1 99.999%; the automatic control lifting device 8 can automatically control the up and down reciprocating movement of the non-consumable tungsten electrode 10 according to the set program, and then can gradually heat the material 6 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 To illustrate this embodiment, an observation and temperature measuring port 7 is opened on the upper end surface of the furnace body 4 of this embodiment, and a water inlet 13 and a water outlet 14 are opened at the lower part of the furnace body 4 . Set in this way, the water inlet 13 and the water outlet 14 are all located at the bottom of the furnace body, in order to ensure that the furnace body 4 and the water-cooled copper crucible 12 are sufficiently cooled to ensure the safety of the equipment; the observation and temperature measurement port 7 is convenient for observing the casting situation at any time. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com