Waterborne epoxy curing agent, preparation method thereof and waterborne epoxy coating

A technology of water-based epoxy and water-based epoxy resin, applied in the field of coatings, can solve the problems of unsatisfactory mechanical properties and resistance of coating films, general water dilution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

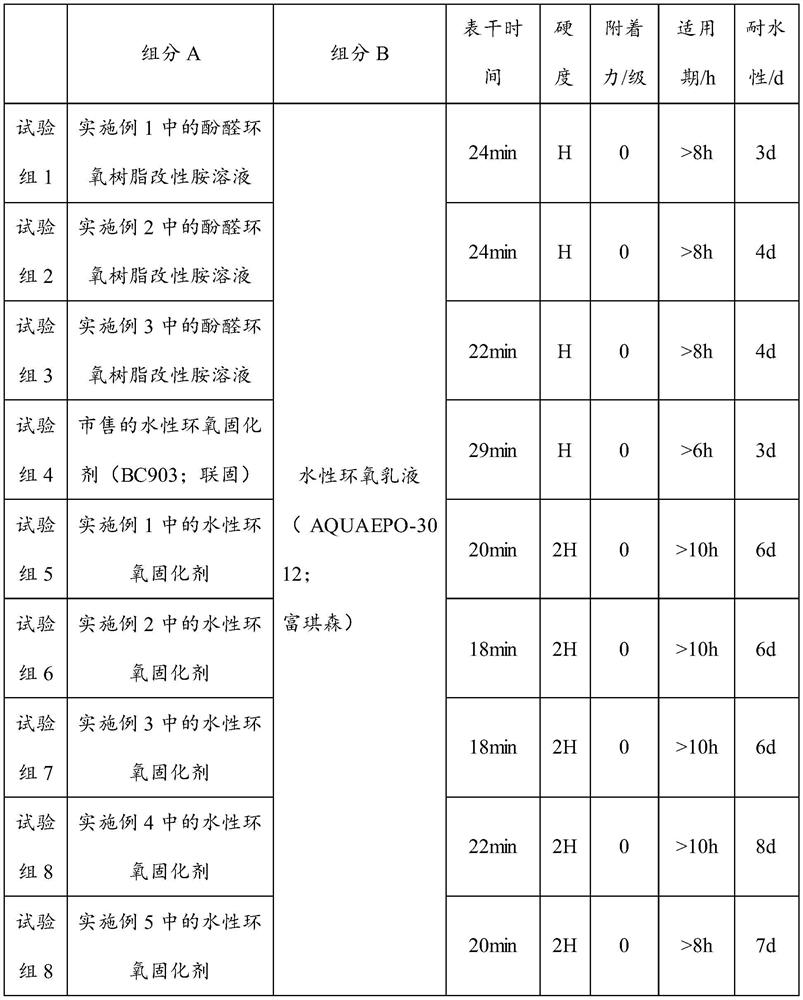

Examples

preparation example Construction

[0033] The embodiment of the present application provides a kind of preparation method of above-mentioned waterborne epoxy curing agent, it comprises the following steps:

[0034] Step 1, preparing novolac epoxy resin modified amine solution.

[0035] As an embodiment, the novolak epoxy resin modified amine solution is mainly obtained by mixing and reacting 30 parts of novolac epoxy resin, 25-35 parts of organic fatty amine and 25-35 parts of solvent in parts by mass. Wherein, the organic aliphatic amine corresponds to the R group, and may include at least one of ethylenediamine, hexamethylenediamine, diethylenetriamine, tetraethylenepentamine and polyethylenepolyamine. The solvent is used to dissolve organic aliphatic amines and novolac epoxy resins, such as propylene glycol methyl ether and ethylene glycol butyl ether.

[0036] Specifically, the preparation method of novolak epoxy resin modified amine solution comprises the following steps:

[0037] Mix and stir the organi...

Embodiment 1

[0043] The present embodiment provides a water-based epoxy curing agent, which is prepared according to the following steps:

[0044] Step 1, prepare novolac epoxy resin modified amine solution:

[0045] In parts by weight, pour 15 parts by weight of propylene glycol methyl ether into a three-necked flask, then add 30 parts by weight of diethylenetriamine (organic fatty acid), and stir to dissolve diethylenetriamine in propylene glycol methyl ether to obtain a dissolved solution ; Slowly add 30 parts by weight of novolac epoxy resin dissolved by 15 parts by weight of propylene glycol methyl ether slowly in the three-necked flask subsequently, control the temperature of the solution in the three-necked flask during the dropping process at 60 ° C, continue to insulate after the dropwise addition After reacting for 3 hours, the solid content was adjusted to 50% by adding deionized water and stirring to obtain a novolak epoxy resin modified amine solution.

[0046] The novolak ep...

Embodiment 2

[0053] The present embodiment provides a water-based epoxy curing agent, which is prepared according to the following steps:

[0054] Step 1, prepare novolac epoxy resin modified amine solution:

[0055] In parts by weight, pour 15 parts by weight of propylene glycol methyl ether into a three-necked flask, then add 30 parts by weight of ethylenediamine, and stir to dissolve ethylenediamine in propylene glycol methyl ether to obtain a dissolved solution; Slowly add 30 parts by weight of novolac epoxy resin dissolved by 15 parts by weight of propylene glycol methyl ether dropwise in the flask, control the temperature of the solution in the three-necked flask during the dropping process at 60 ° C, continue the insulation reaction for 2 hours after the dropwise addition, adjust the solid Containing 50%, prepared novolak epoxy resin modified amine solution.

[0056] The novolak epoxy resin modified amine solution is a light yellow liquid with a solid content of 50% and a viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com