A kind of modified waterborne polyester resin with high dicyclopentadiene content and its preparation method and application

A technology of water-based polyester resin and dicyclopentadiene, which is applied in the field of resins and coatings, and can solve the problems of low dicyclopentadiene content and no reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

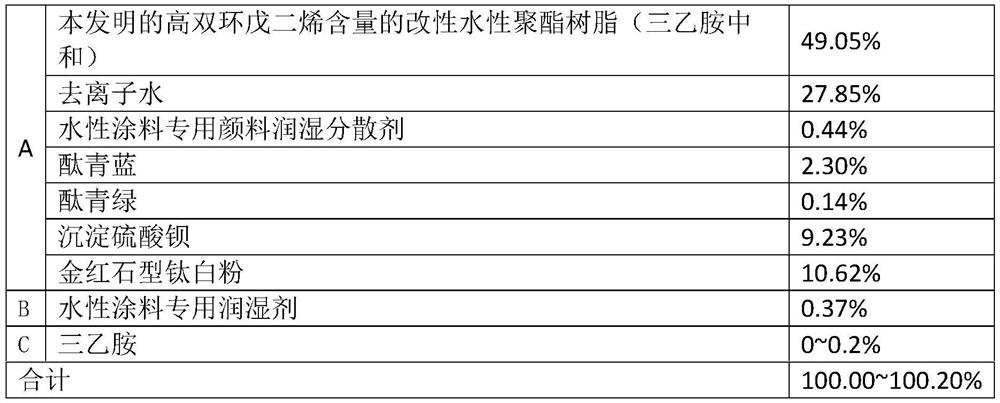

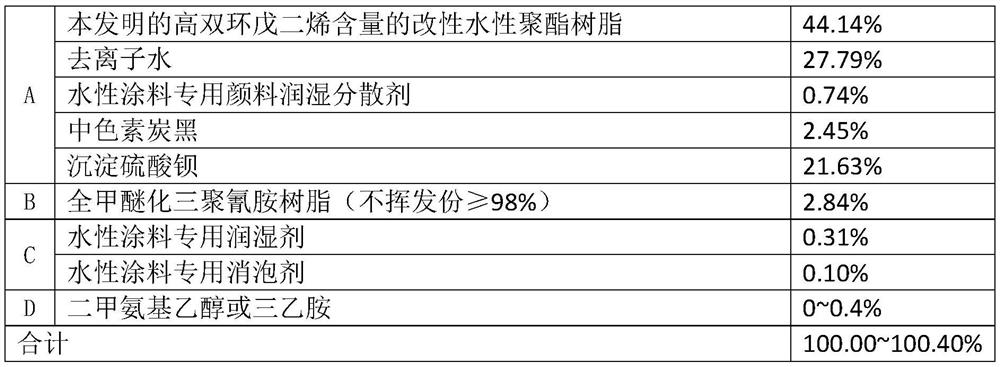

Examples

Embodiment 1

[0032] S1: put in dicyclopentadiene①, p-methoxyphenol, maleic anhydride①, introduce nitrogen, stir and heat up to 115~120℃ and keep it, start to drip water①, the dripping time is 0.5h, and the water dropwise addition is completed Then, continue to keep the reaction at 115~120℃ until the acid value of the material is measured to be equal to 197.4mgKOH / g (the half-esterification rate of maleic anhydride is 98.8%), and then the temperature is lowered;

[0033] S2: Throw in trimellitic anhydride, dimethylol propionic acid, dimethylol butyric acid and maleic anhydride ②, heat up to 160-165°C without refluxing through a water separator for 0.75h;

[0034] S3: Cool down and put in maleic acid ③, phthalic anhydride, glycerol, trimethylolpropane, pentaerythritol, use methyl isobutyl ketone as a reflux solvent, heat up to 165~195 ℃ and conduct a reflux dehydration reaction through a water separator; The acid value of the obtained material was reduced to 63.5mgKOH / g, and the temperature ...

Embodiment 2

[0038] S1: Throw in dicyclopentadiene①, p-methoxyphenol and maleic anhydride①, introduce nitrogen, stir and heat up to 105-110°C and keep it, start dripping water for 1.5h, after the water is added dropwise, Continue to keep the reaction at 110~115°C until the acid value of the material is measured to be equal to 201.6 mgKOH / g (the half-esterification rate of maleic anhydride is 98.9%), and cool down;

[0039] S2: Throw in trimellitic anhydride, dimethylolpropionic acid and maleic anhydride ②, heat up to 155-160°C, and react for 1.5h without refluxing through a water separator;

[0040] S3: drop in phthalic anhydride, diethylene glycol, glycerol, and trimethylolpropane for cooling, use methyl isobutyl ketone as a reflux solvent, heat up to 165-195 °C, and conduct a reflux dehydration reaction through a water separator; when the measured acid value of the material drops to 62.2mgKOH / g, cooling;

[0041] S4: add dicyclopentadiene ② and p-toluenesulfonic acid, heat up to 130~135...

Embodiment 3

[0044] S1: put in dicyclopentadiene①, p-methoxyphenol and maleic anhydride①, introduce nitrogen, stir and heat up to 110-115°C and keep it, start dripping water for 1h, after the water is added dropwise, continue Incubate the reaction at 110~115°C until the acid value of the material is measured to be equal to 201.8 mgKOH / g (the half-esterification rate of maleic anhydride is 98.7%), and then cool down;

[0045] S2: Throw in trimellitic anhydride, dimethylolpropionic acid and maleic anhydride ②, heat up to 155-160°C, and react for 1.5h without refluxing through a water separator;

[0046] S3: drop in adipic acid, phthalic anhydride, maleic anhydride ③, glycerol, trimethylolpropane, use methyl isobutyl ketone as a reflux solvent, be warming up to 165~195 ℃ through a water separator reflux dehydration reaction; When the measured acid value of the material drops to 64.2mgKOH / g, the temperature is lowered;

[0047] S4: add dicyclopentadiene ② and p-toluenesulfonic acid, heat up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com