A kind of method for producing hydroxylamine hydrochloride

A technology of hydroxylamine hydrochloride and production equipment, applied in the direction of hydroxylamine, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficulty in realizing large-scale industrial production, difficulty in realizing industrial production, complicated process, etc., and achieve large-scale industrialization The effect of production, easy industrialization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

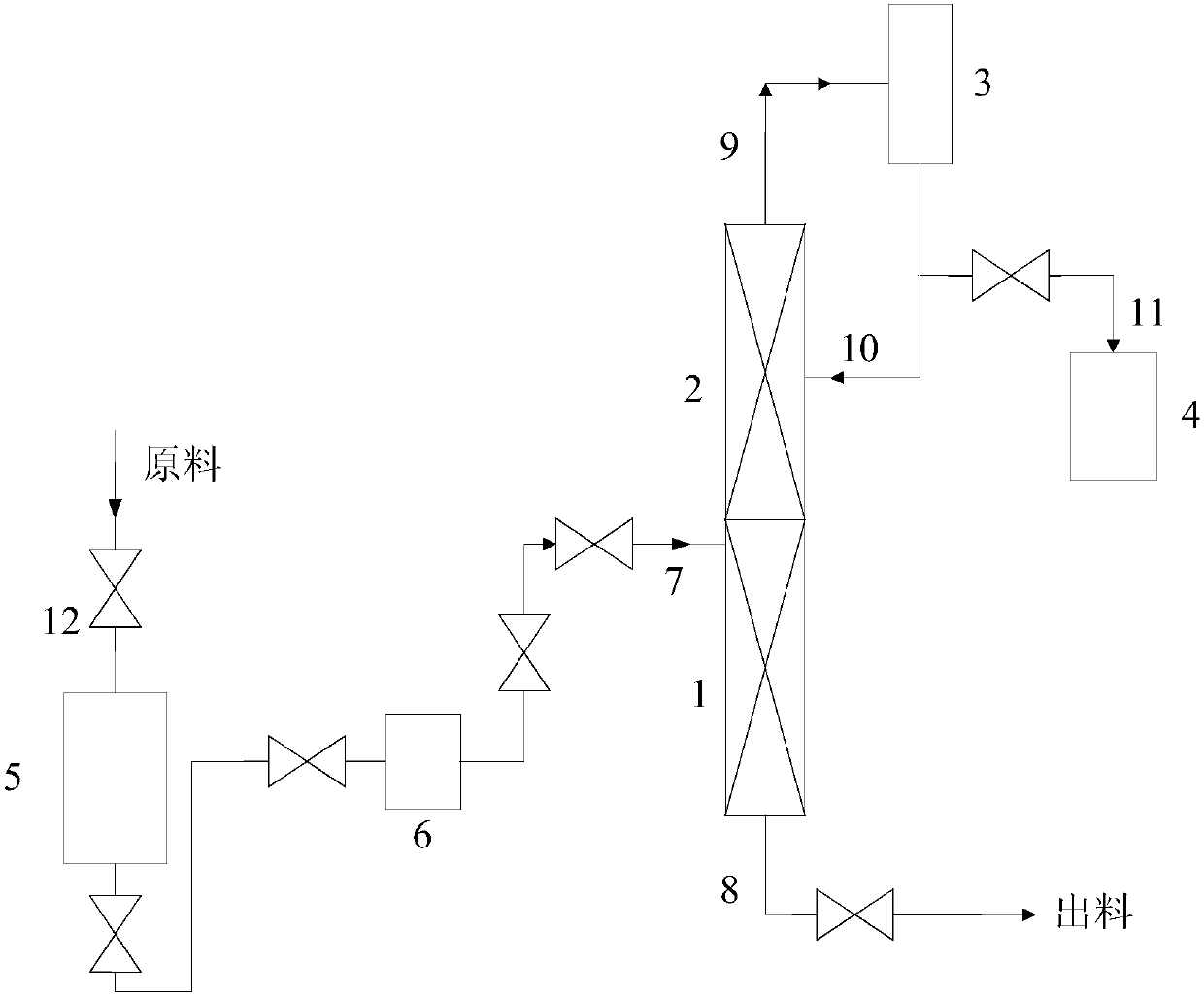

[0027] First, put butanone oxime and hydrochloric acid into the premixing tank 5 for premixing according to the molar ratio of butanone oxime and hydrochloric acid 1.1:1, and the jacket of the condenser 3 is fed with a cold medium, and then the reaction system is evacuated to -0.07Mpa. Reactor 1 is heated up to the reaction temperature of 80°C, and the feed metering pump 6 is started, and the raw materials in the premix tank 5 are poured into the tubular reactor 1 for reaction, and the residence time is 250s. Distillation and separation tower 2 separates the mixture of methyl ethyl ketone and water, after the mixture of methyl ethyl ketone and water is cooled by condenser 3, part of it is refluxed to rectification and separation tower 2, and part of it is collected in collection tank 4. The tubular reactor discharge pipe 8 at the bottom of the reactor 1 collects, concentrates, filters, and dries to obtain hydroxylamine hydrochloride. The raw materials were injected continuousl...

Embodiment 2

[0029] The residence time is 150s, the system is vacuumed to -0.06Mpa, and the others are the same as in Example 1, 613.6g of hydroxylamine hydrochloride can be obtained, the yield is 98.1%, and the content is 98.9%.

Embodiment 3

[0031] The reaction temperature was 70° C., the residence time was 300 s, the others were the same as in Example 1, and 614.2 g of hydroxylamine hydrochloride could be obtained, with a yield of 98.2% and a content of 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com