Process for drawing low-light-attenuation single crystal, single crystal, silicon rod, silicon wafer, battery and assembly

A single crystal and process technology, applied in photovoltaic power generation, electrical components, single crystal growth, etc., can solve the problems of conversion efficiency attenuation, accelerate the attenuation of single crystal conversion efficiency, etc., achieve low attenuation rate, reduce RRV failure, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

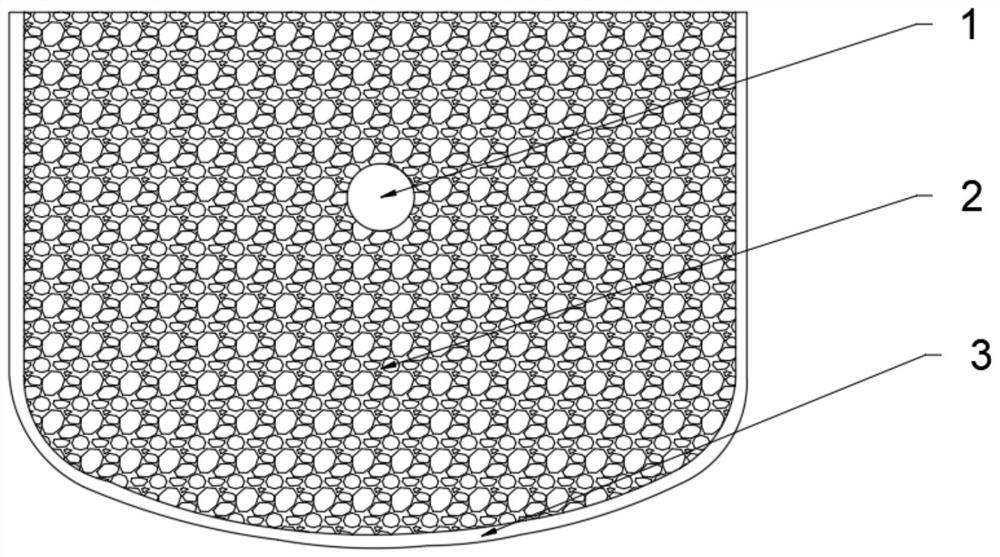

[0024] figure 1 It shows a schematic diagram of the placement position of dopants during charging according to one embodiment of the present invention. Cells and components are used for Czochralski single crystals. In the process of Czochralski single crystals, dopants are added to reduce boron-oxygen complexes in the process of single crystal growth, thereby reducing the light decay of single crystals. At the same time , in the single crystal pulling process, in the process of stabilizing the temperature to the equal diameter process, the high crystal transfer process is used to reduce the RRV failure of the single crystal and improve the gradient distribution of the single crystal. In the process of pulling multiple single crystals, the dopant is supplemented to reduce the working hours; at the same time, in the process of pulling single cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com