Novel cantilever steel scaffold and construction process thereof

A scaffolding and cantilevering technology, which is applied to the accessories of scaffolding, scaffolding supported by house structure, and construction, etc., can solve the problem of uneven stress on I-beams and floors, difficulty in masonry construction of cantilevered layers, and increase the limitations of scaffolding. and other problems, to achieve the effect of easy disassembly and recycling, repeated turnover, easy automatic correction, and stable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

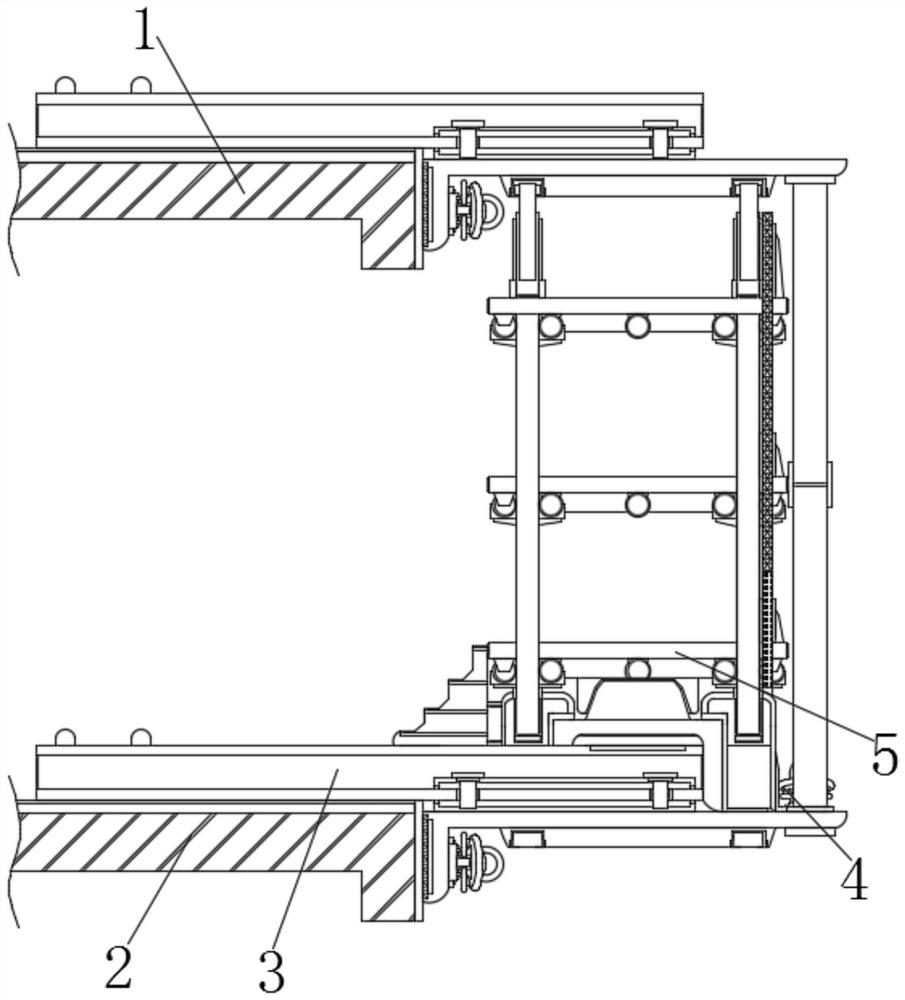

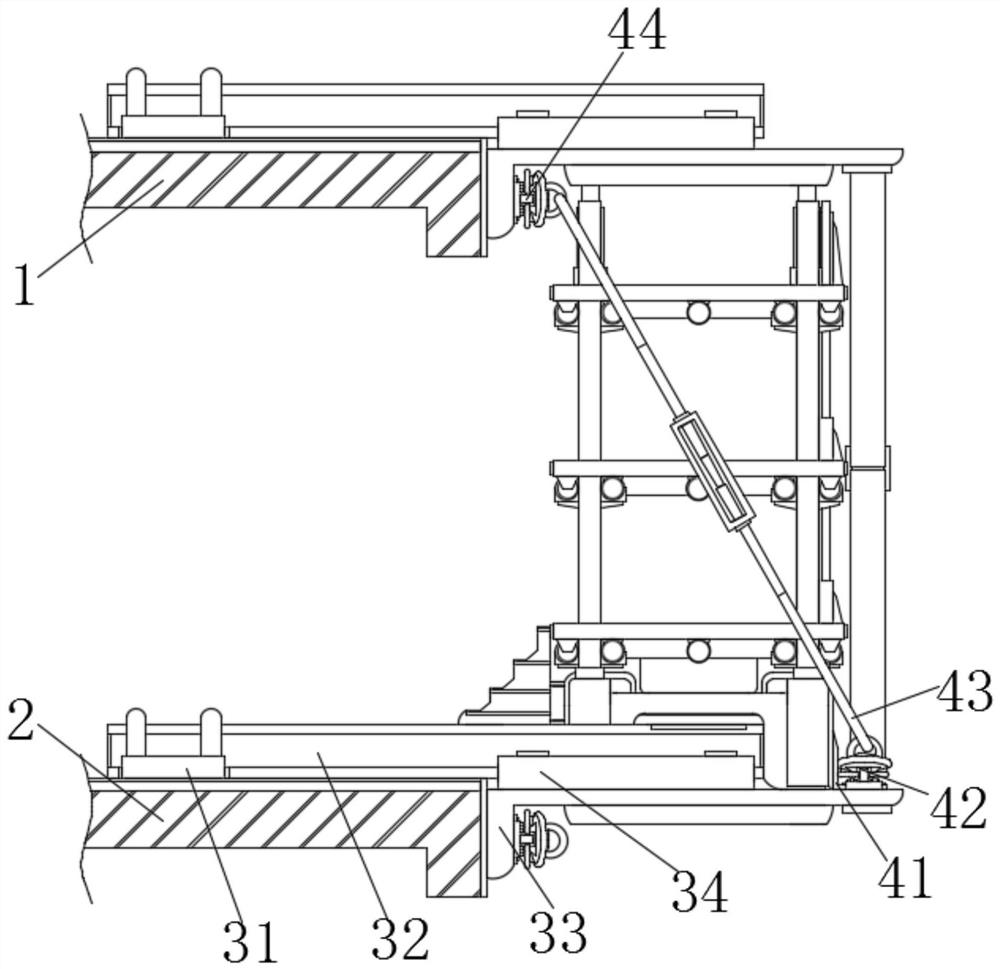

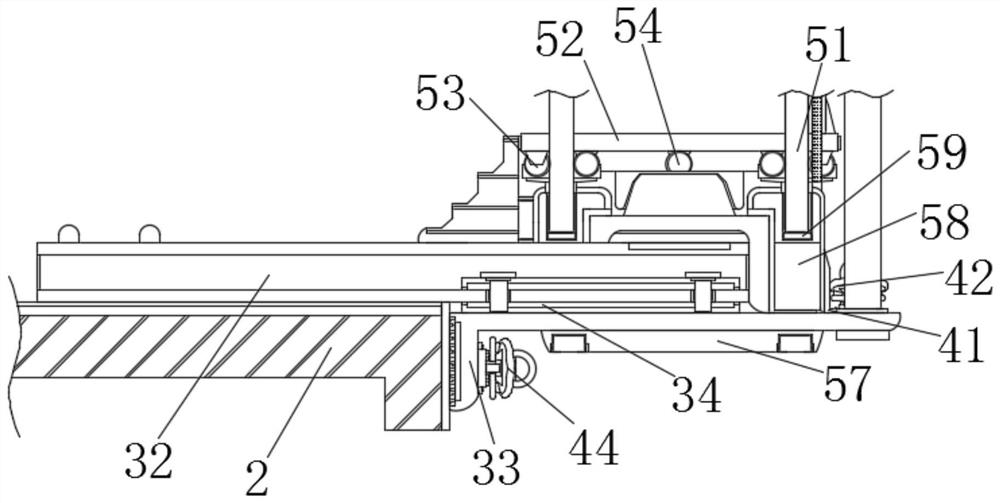

[0045] Example 1, such as image 3 As shown, when the scaffolding is fixed on the top of the I-shaped steel 32, the connection between the first ear plate 42 and the platform seat 58 can be fixed through the connecting support 41, so that the turnbuckle 43 can be installed on the L-shaped support plate 33 as a whole at the same time. The designed main structure is reinforced and supported, which greatly improves the stability of the outer scaffold, and the sleeve 59 provided by the cap seat 58 is matched with the trapezoidal fixing seat and the trapezoidal fixing groove to further improve the relationship between the scaffold and the I-shaped steel 32 structure. The tightness and positioning effect of the connection between them.

Embodiment 2

[0046] Example 2, such as Figure 5-6 As shown, the I-shaped steel 32 can be provided with a positioning hole at a designated position on the ground in advance, and the sliding kit 34 can be slid into the outside of the I-shaped steel 32 and fixed by positioning bolts, and then the L-shaped support plate 33 and the sliding The set 34 is welded into an integrated structure, so that the integrated structure of the I-shaped steel 32, the L-shaped support plate 33 and the sliding set 34 can be quickly contacted and positioned with the upper floor 1 and the lower floor 2, providing the structure between floors. fit and support strength.

[0047] Working principle: When the device is in use, the integrated structure of the I-shaped steel 32, the sliding set 34 and the L-shaped support plate 33 can be used to quickly position and splice the I-shaped steel 32 with the upper floor 1 or the lower floor 2 to promote The overall supporting force of the I-shaped steel 32 is more uniform, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com