Smoke waste heat recovery and hot water white smoke elimination system and working method thereof

A flue gas waste heat and hot water technology, applied in heat pumps, climate sustainability, greenhouse gas reduction, etc., can solve the problems of incomplete flue gas waste heat recovery, complicated process, and inability to achieve flue gas whitening, and achieve simple structure , Avoid environmental pollution, improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

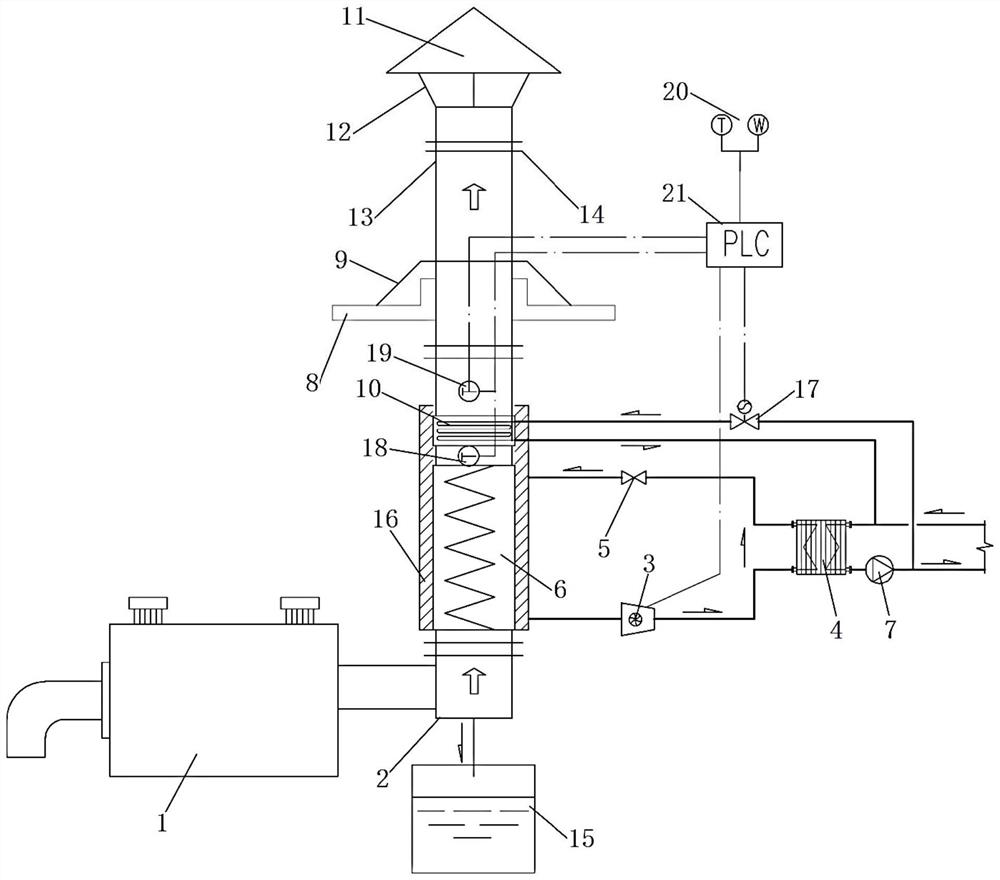

[0055] as attached figure 1 As shown, this embodiment provides a flue gas waste heat recovery and hot water whitening system, including a flue gas discharge system, a waste heat recovery system, a flue gas whitening system, and a monitoring and control system.

[0056] The flue gas discharge system includes a flue 2, a wind cap 11, a fixed support 12 and a water collection tank 15; The gas discharge side port is connected; the flue 2 is arranged vertically and runs through the roof panel 8 or the cover plate; the conical cover 9 is set on the outside of the flue 2 and is fixedly connected with the roof panel 8 or the cover plate; Set on the top of the flue 2, the wind cap 11 is set on the top of the fixed support 12; wherein, the wind cap 11 adopts a round umbrella-shaped wind cap; in this embodiment, the flue 2 adopts a flue; the flue 2 includes several flue pipe joints 13 , a number of flue pipe joints 13 are spliced vertically sequentially, and flanges 14 are fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com