Pure electric loader transmission

A transmission and loader technology, applied in the field of pure electric loader transmission, can solve the problems of large input and output height difference of transmission, large working torque and impact load, complex structure and layout, etc., to improve transmission efficiency, reduce height difference, transmit clear route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

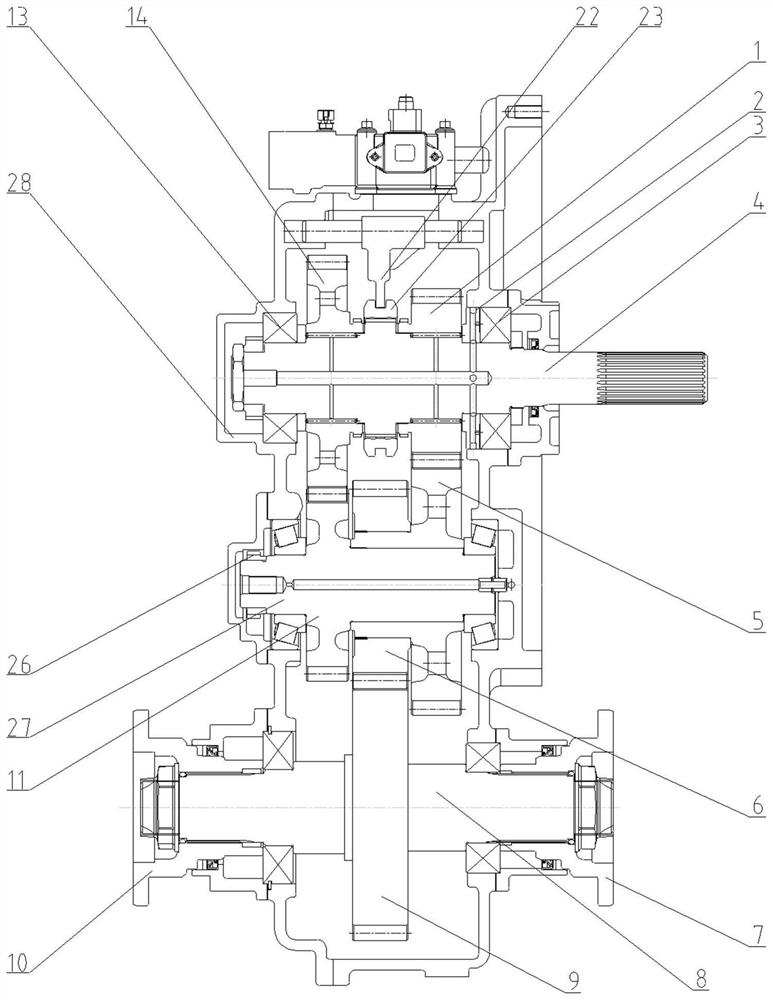

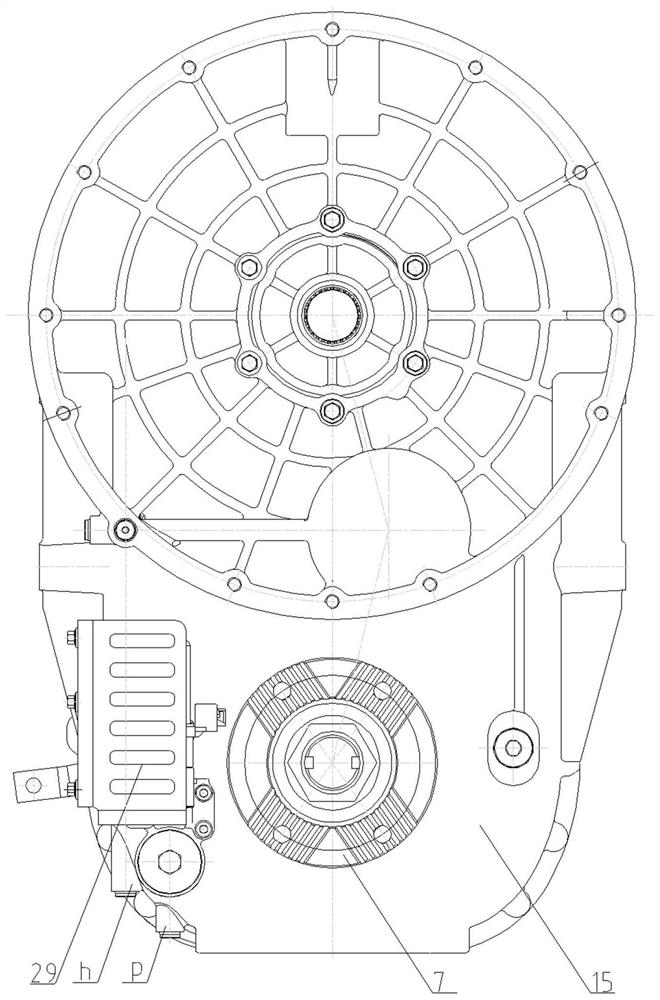

[0045] A pure electric loader transmission, such as figure 1 As shown, including the transmission body, the transmission body is provided with a transmission front housing 15 and a transmission rear housing 28, and an input shaft 4, an intermediate shaft 27 and an output shaft 8 are sequentially installed in the transmission body from top to bottom; on the input shaft 4 The first gear 1 of the input shaft and the second gear 14 of the input shaft are sleeved, and the input shaft 4 is connected with an external power source; the first gear 5 of the intermediate shaft, the second gear 11 of the intermediate shaft and the intermediate shaft Output gear 6, intermediate shaft output gear 6 is located between intermediate shaft first gear 5 and intermediate shaft second gear 11, intermediate shaft first gear 5 meshes with input shaft first gear 1, intermediate shaft second gear 11 and input shaft The second gear 14 meshes, and the intermediate shaft output gear 6 is fixedly connecte...

Embodiment 2

[0047] Except for the following content, all the other contents are the same as in Example 1.

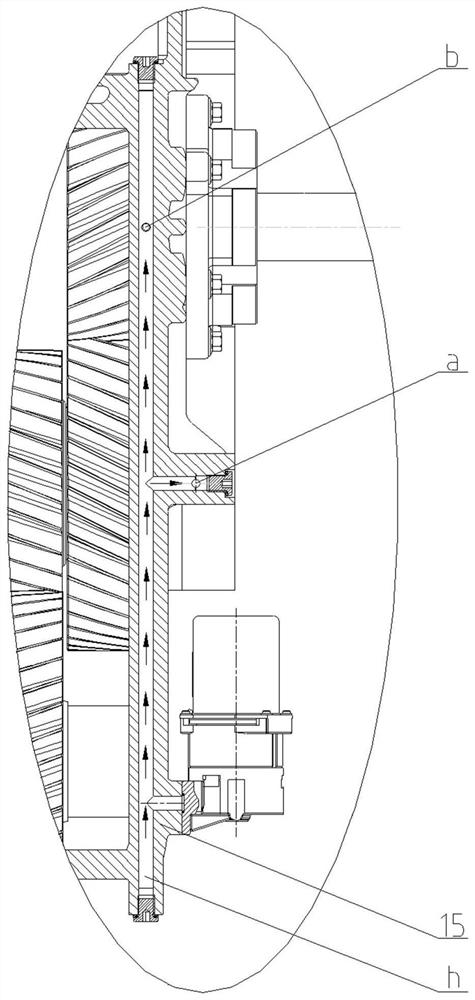

[0048]An electronic oil pump 16 is installed outside the lower end of the transmission front housing 15, and an oil filter plug 25 and an oil filter 24 are installed on the lower side of the electronic oil pump 16; the transmission front housing 15 is provided with a first oil passage and a second oil passage; The oil inlet of the electronic oil pump 16 is connected to the second oil passage, the oil outlet of the electronic oil pump 16 is connected to the first oil passage, the first oil passage is the main oil passage, and two oil passage branches are arranged on the main oil passage, respectively The first oil path branch and the second oil path branch, the first oil path branch is connected to the input shaft 4 , and the second oil path branch is connected to the intermediate shaft 27 . The front casing 15 of the transmission is provided with a threaded through hole, and the oil...

Embodiment 3

[0050] Such as figure 1 As shown, the present invention provides a pure electric loader transmission, including an input shaft 4 , an intermediate shaft 27 , and an output shaft 8 arranged in the front housing 15 of the transmission. The input shaft 4 is respectively sleeved with the first gear 1 of the input shaft and the second gear 14 of the input shaft through four sets of needle bearings 17 . The intermediate shaft 27 is respectively provided with the intermediate shaft first gear 5 and the intermediate shaft second gear 11 meshing with the input shaft first gear 1 and the input shaft second gear 14 . Wherein, the countershaft second gear 11 and the countershaft 27 are integrally arranged. The intermediate shaft 27 is also provided with an intermediate shaft output gear 6 welded integrally with the intermediate shaft first gear 5 , and the intermediate shaft first gear 5 is in interference connection with the intermediate shaft 27 . The output shaft 8 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com