Intelligent large-scale card insertion type optical module testing device

An optical module testing, plug-in technology, applied in the direction of measuring device, optical instrument testing, machine/structural component testing, etc., can solve the problems of high error rate, cumbersome steps, a large number of devices, etc. The effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

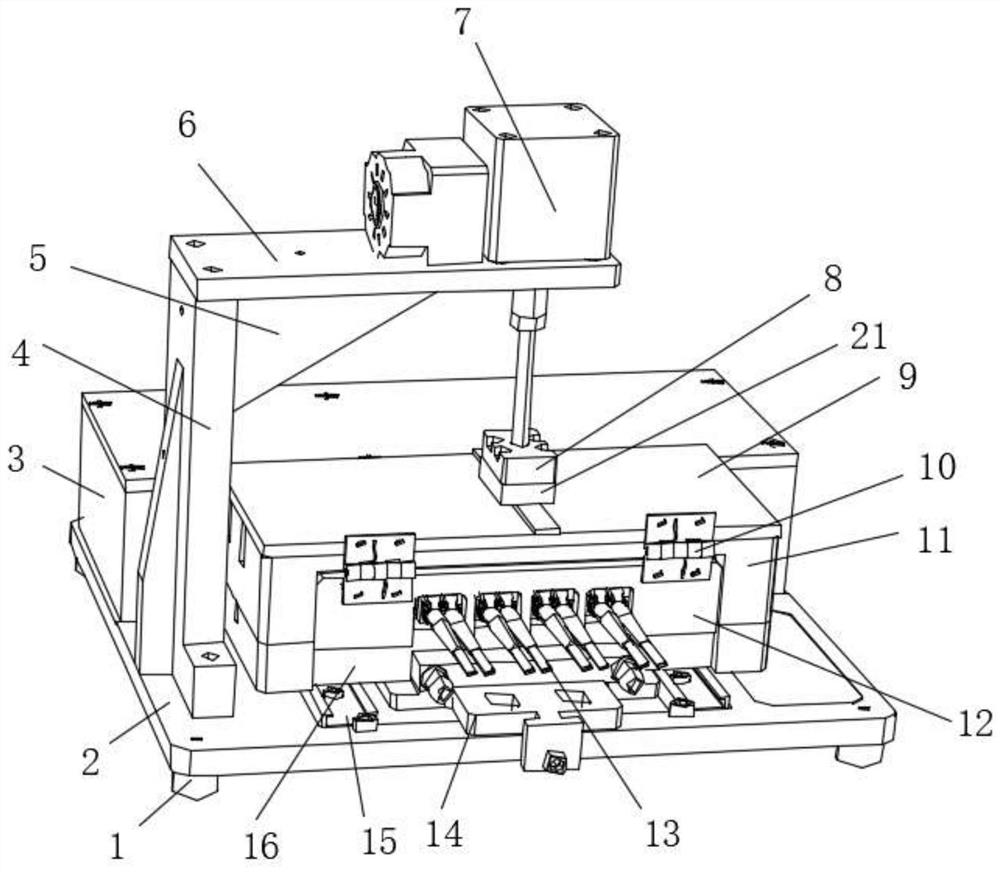

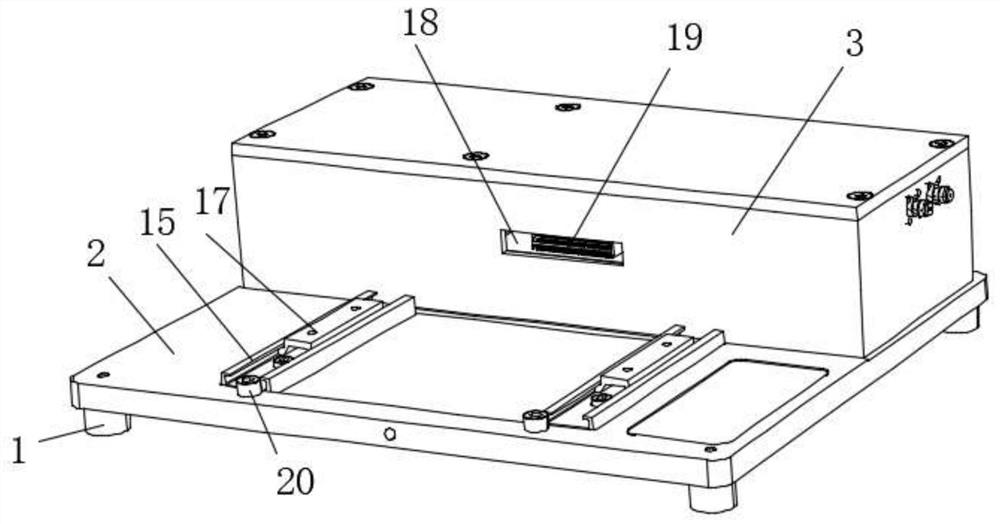

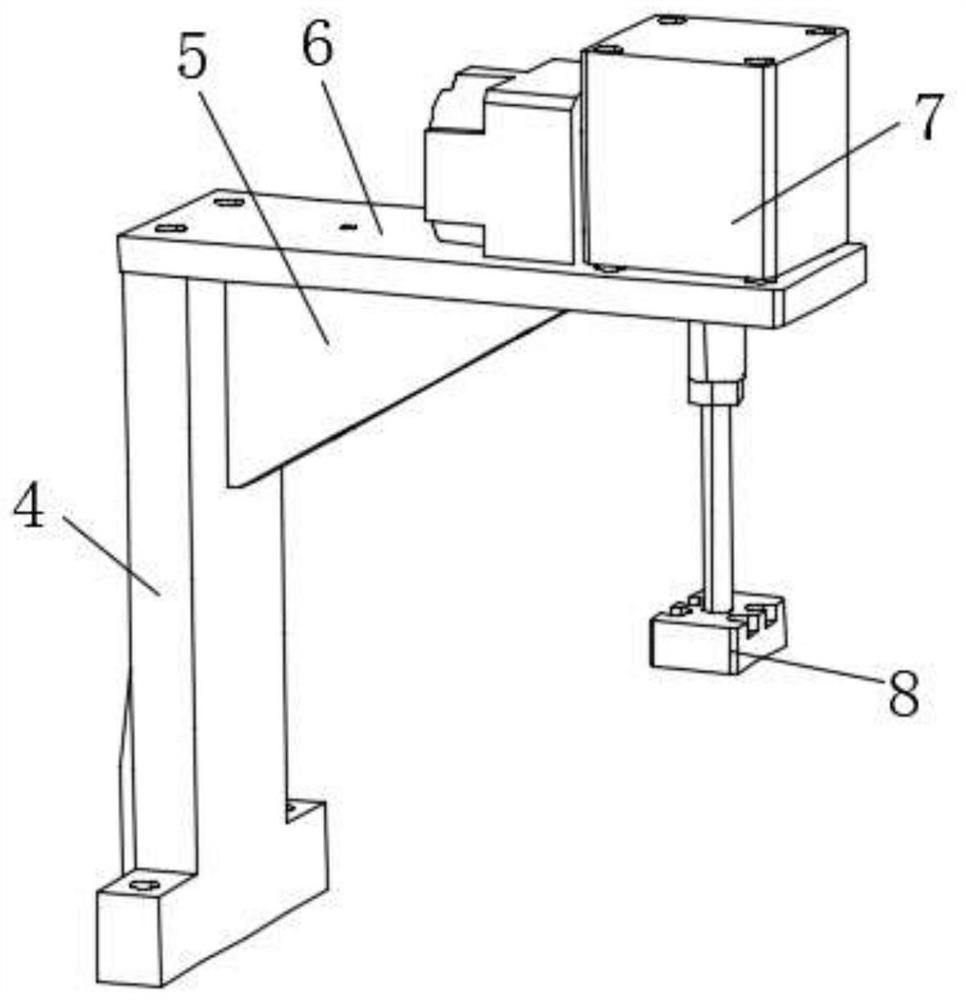

[0037] refer to Figure 1-11 , an intelligent large-scale plug-in type optical module testing device, including a base plate 2, an optical module body 13 and a fixed box 58, the top of the base plate 2 is fixedly connected with a main test box 3, and one side of the main test box 3 is provided with The briquetting groove 18, the inside of the main test box 3 is provided with a multi-pin connector socket 19, the top of the bottom plate 2 is slidably connected with a sliding plate 14, the top of the bottom plate 2 is fixedly connected with a riser 4, and one side of the riser 4 is slidably connected There is a cover plate 9, the bottom of the cover plate 9 is fixedly connected with an upper test box 11, the top of the vertical plate 4 is provided with a pneumatic lifting mechanism for lifting the height of the cover plate 9, the top of the sliding plate 14 is fixedly connected with a lower test box 16, and the bottom of the vertical plate 4 is fixedly connected with a lower test ...

Embodiment 2

[0039] refer to Figure 1-11 , the present invention proposes a technical solution, an intelligent large-scale plug-in type optical module testing device, comprising a base plate 2, an optical module body 13 and a fixed box 58, the top of the base plate 2 is fixedly connected with a main test box 3, the main One side of the test box 3 is provided with a briquetting groove 18, the inside of the main test box 3 is provided with a multi-pin connector socket 19, the top of the bottom plate 2 is slidably connected with a sliding plate 14, and the top of the bottom plate 2 is fixedly connected with a riser 4, One side of the riser 4 is slidingly connected with a cover plate 9, and the bottom of the cover plate 9 is fixedly connected with an upper test box 11. The top of the riser 4 is provided with a pneumatic lifting mechanism for raising the height of the cover plate 9. The pneumatic lifting mechanism includes a fixed connection On the top plate 6 at the top of the vertical plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com