Lumbar puncture training module and manufacturing method thereof

A training module and lumbar puncture technology, which is applied in the field of medical education, can solve problems such as difficulty in ensuring consistent puncture needles, affecting the effect of puncture training, and difficult to fit tightly between tissues, so as to ensure the needle feel and improve the overall appearance , the effect of precise size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

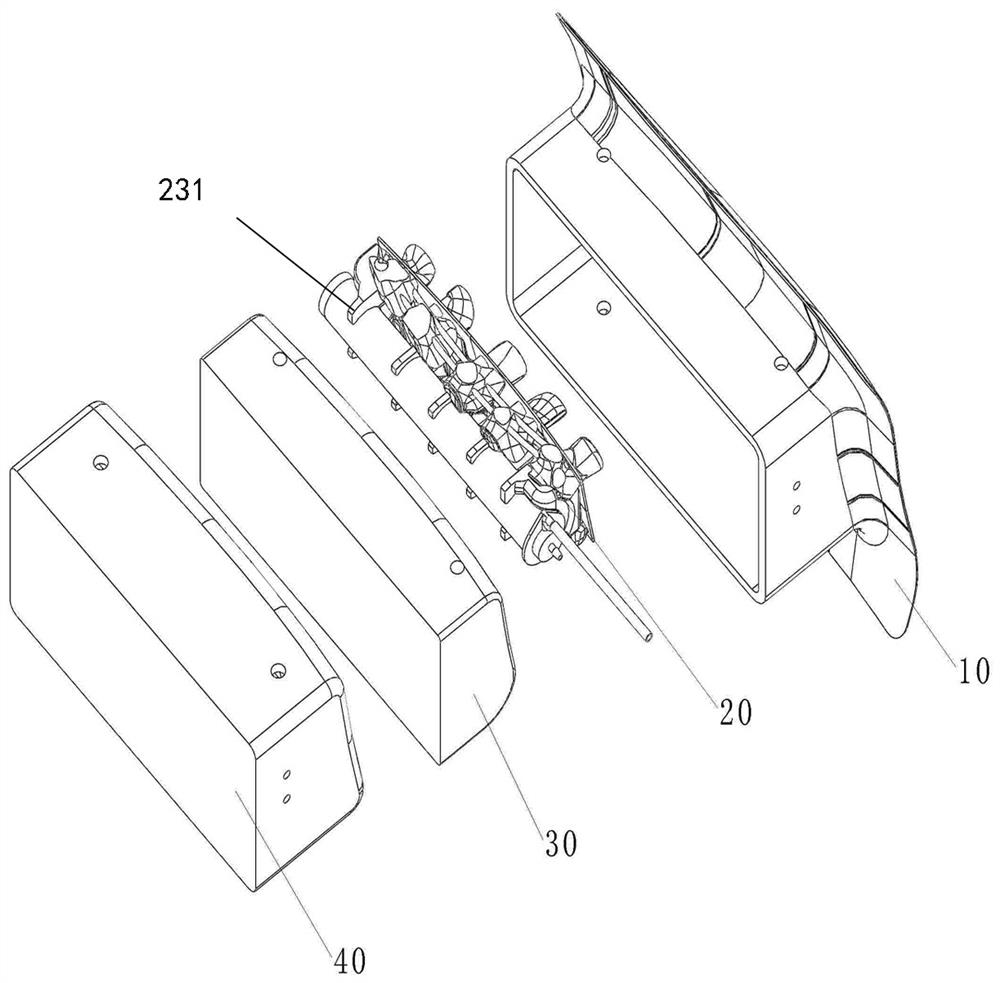

[0046] Specific embodiment 1 a kind of lumbar puncture training module, such as Figure 1~4 As shown, it includes simulated outer skin (10), simulated lumbar vertebra (20), simulated supraspinal ligament and interspinous ligament (30), simulated subcutaneous tissue (40), and simulated ligamentum flavum is set on the simulated lumbar vertebra (20) (60), simulation puncture tube (50); described simulation puncture tube (50) is arranged on simulation puncture tube (50) described in simulation lumbar vertebrae (20) inner chamber and comprises simulation spinal canal (52) and simulation hard meninges (51); the simulated ligamentum flavum (60) is set in the external cavity of the simulated lumbar vertebrae (20); the simulated lumbar vertebrae (20) are wrapped in the simulated supraspinal ligament and interspinous ligament (30), The simulated subcutaneous tissue (40) wraps the simulated supraspinal ligament and interspinous ligament (30), and the simulated skin (10) wraps the simulat...

specific Embodiment 2

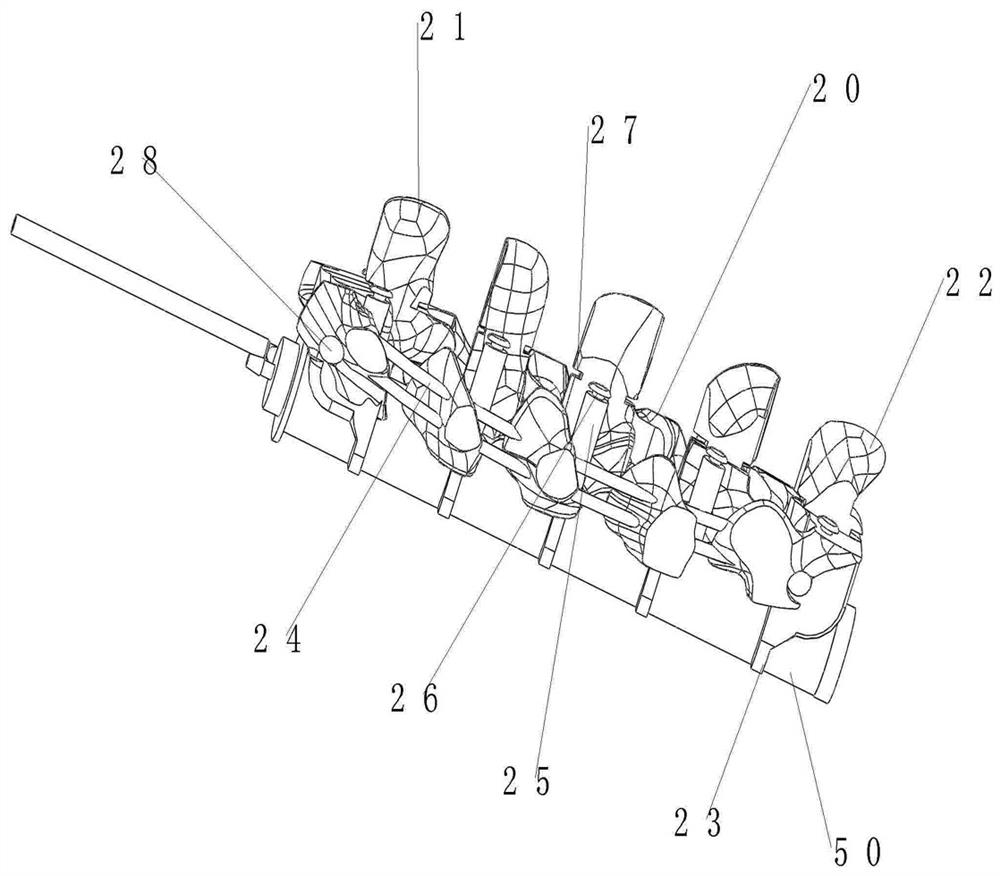

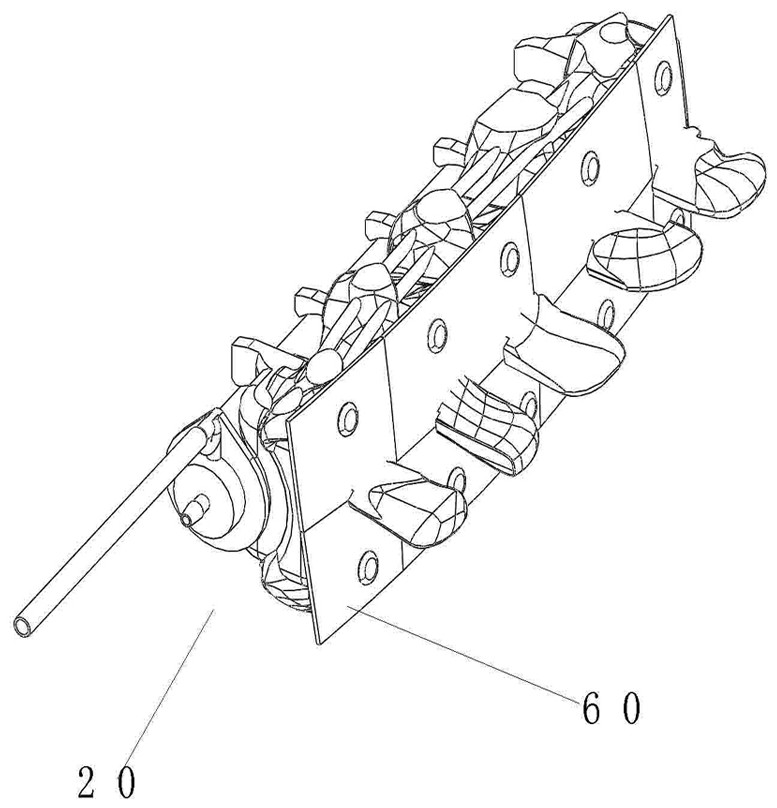

[0047] Specific embodiment 2 The simulated lumbar vertebrae described in this embodiment, such as Figure 2~3 Shown is a 3D printed complete simulated lumbar vertebra (20) with vertebrae 1 to 5. A shallow groove (27) is set on each spinous process of the first vertebra (21) to the fifth vertebra (22) of the 3D printed artificial lumbar vertebra (20), and the position of the shallow groove (27) is At 11mm away from the top of each spinous process, the shallow groove (27) has a height and depth of 1mm. Cylinders (25) are respectively arranged on both sides of each spinous process, and a 1mm annular shallow groove (26) is opened at a place 1mm away from the top of the cylinder (25). Open 1mm shallow grooves (26) on the cylinders (25) arranged on both sides of each spinous process, the purpose is to fix the simulated ligamentum flavum (60) on the simulated lumbar vertebrae (20), and pass 3 shallow grooves (26) on each vertebrae. The groove is used to fix the simulated ligamentum...

Embodiment 3

[0050] Example 3 as figure 2 and Figure 4 As shown, the simulated puncture tube described in this embodiment includes a simulated dura mater (51) and a simulated spinal canal (52), and the simulated puncture tube (50) is set on the 3D printed simulated lumbar vertebra ( 20) in the "C" type fixed structure 231). In this embodiment, the materials used for the simulated dura mater (51) and the simulated spinal canal (52) are soft materials. The soft material is specifically a latex tube and a silicone tube, the latex tube is used to simulate the simulated dura mater (51) in the simulated puncture tube, and the silicone tube is used to simulate the simulated spinal canal (51) in the simulated puncture tube ( 52). The size of the latex tube is 148mm in length and 14*18mm in diameter, and the size of the silicone tube is 140mm in length and 8*11mm in diameter. The silicone tube is sleeved in the latex tube, one end is blocked with a T-shaped silicone plug (53), and one end is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com