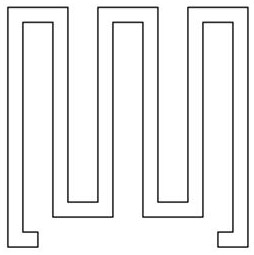

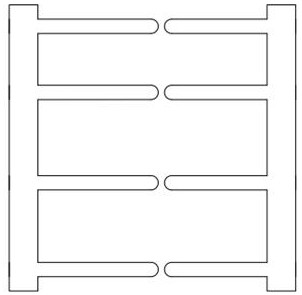

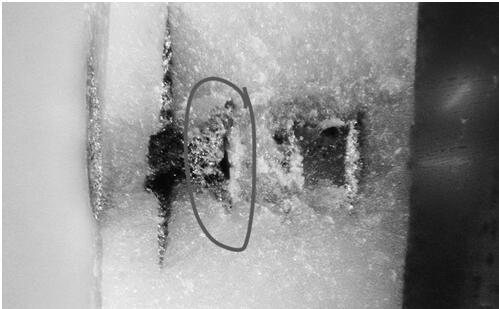

Transition pore-filling slurry for connecting upper and lower gold and silver layers of film belt in LTCC (Low Temperature Co-Fired Ceramic) substrate

A technology for connecting films and substrates, applied in the field of transition filling paste, can solve problems such as migration, and achieve the effects of good electrical conductivity, good electrical conductivity and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 8g of gold powder, 70g of silver powder, 2g of platinum powder, 5g of Ca-B-Si glass powder, 10g of TiN powder, and 5g of organic carrier, stir evenly with a glass rod, and place it for more than 1 hour to complete infiltration, and then roll on a three-roller machine , so that the fineness ≦ 15μm, to obtain transitional hole filling slurry.

Embodiment 2

[0026] Weigh 12.5g of gold powder, 63.5g of silver powder, 7g of platinum powder, 3g of Ca-B-Si glass powder, 9g of TiN powder, and 5g of organic carrier, stir evenly with a glass rod, and place it for more than 1 hour to complete infiltration, and then put it on a three-roll machine Rolling to make the fineness≦15μm, to obtain transitional hole filling slurry.

Embodiment 3

[0028] Weigh 12.5g of gold powder, 63.5g of silver powder, 7g of platinum powder, 3g of Ca-B-Si glass powder, 4g of TiN powder, and 10g of organic carrier, stir evenly with a glass rod, and place it for more than 1 hour to complete infiltration, and then put it on a three-roller machine Rolling to make the fineness≦15μm, to obtain transitional hole filling slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com