Method for transferring two-dimensional material to hole substrate

A two-dimensional material and substrate technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of weak adsorption capacity, cumbersome materials, and insufficient clean steps on the surface of materials, so as to improve the success rate and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

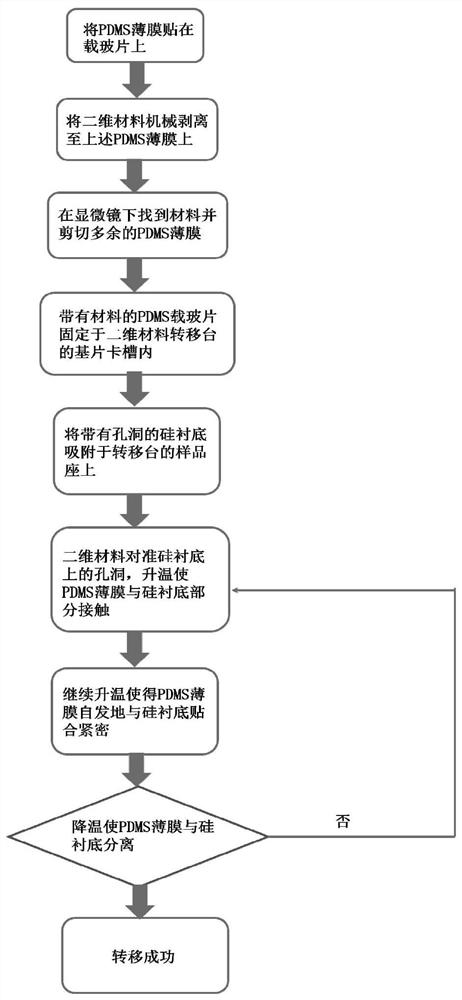

[0028] Embodiments of the present invention include the following steps:

[0029] The first step: cut the polydimethylsiloxane (Polydimethylsiloxane, PDMS) film into a size of 2 × 2cm and stick it on the glass slide;

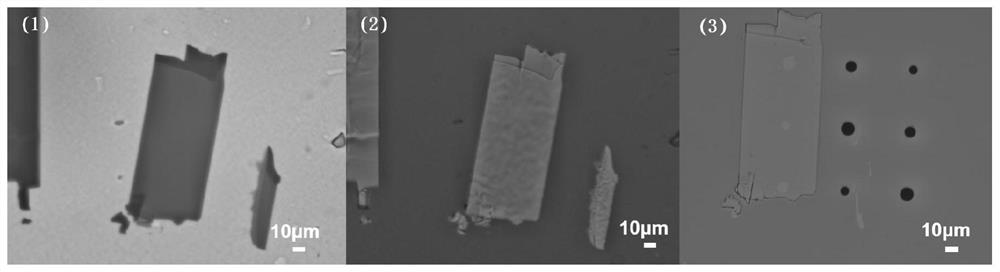

[0030] The second step: the two-dimensional material block is folded in half on the tape several times and then mechanically peeled off to the PDMS film obtained in the first step;

[0031] Step 3: Find the material that has been mechanically peeled off in the second step under the microscope, cut off the excess PDMS film, and cut it into a size of 5×5mm;

[0032] Step 4: Fix the glass slide with material obtained in the third step in the substrate slot of the transfer table;

[0033] Step 5: Adsorb the silicon Si substrate with holes on the sample holder of the transfer table;

[0034] Step 6: Align the materials in step 4 with the holes on the Si substrate precisely, and raise the temperature to 60°C to make the PDMS film partially contact with the substrate...

Embodiment 2

[0038] The first step: cutting the polydimethylsiloxane (PDMS) film into a size of 1 × 1 cm and pasting it on a glass slide;

[0039] The second step: the two-dimensional material block is folded in half on the tape several times and then mechanically peeled off to the PDMS film obtained in the first step;

[0040] Step 3: Find the material that has been mechanically peeled off in the second step under the microscope, cut off the excess PDMS film, and cut it into a size of 3×3mm;

[0041] Step 4: Fix the glass slide with material obtained in the third step in the substrate slot of the transfer table;

[0042] Step 5: Adsorb the silicon Si substrate with holes on the sample holder of the transfer table;

[0043] Step 6: Align the materials in step 4 with the holes on the Si substrate precisely, and raise the temperature to 75°C to make the PDMS film partially contact with the substrate;

[0044] Step 7: Continue to raise the temperature to 110°C and keep it for 15 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com