Waste soil recycling heat preservation building brick and production device thereof

A production device and brick-laying technology, which is applied in the direction of unloading device, layered products, transportation and packaging, etc., can solve the problems of brick-laying production quality and inferior brick quality, and achieve production quality, slow down temperature transfer and The effect of dissipation and reduction of building energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

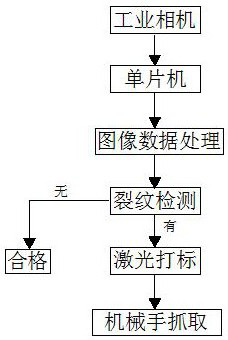

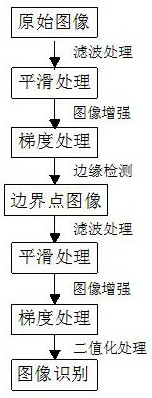

[0049] Such as figure 1 as shown,

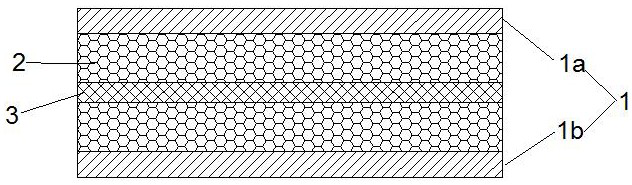

[0050] A kind of waste soil reutilization thermal insulation bricklaying, comprises skeleton layer 1, energy storage layer 2, insulation layer 3; Said skeleton layer 1 comprises upper skeleton layer 1a and lower skeleton layer 1b, and described skeleton layer 1 is made of recycled spoil It is bonded by mixing hard particles, and an energy storage layer 2 is arranged between the upper framework layer 1a and the lower framework layer 1b, and the energy storage layer 2 is formed by bonding energy storage materials and mixing hard particles , the upper surface of the energy storage layer 2 is bonded to the upper skeleton layer 1a, the lower surface of the energy storage layer 2 is bonded to the lower skeleton layer 1b; the center position of the energy storage layer 2 is horizontally bonded There is an insulating layer 3, and the upper skeleton layer 1a, the lower skeleton layer 1b, the energy storage layer 2 and the insulating layer 3 constit...

Embodiment 2

[0055] Such as Figure 2-4 As shown, a production device for reusing waste soil for heat preservation brick laying, including a mechanical module and a detection module, the mechanical module includes a palletizer 4, and the palletizer 4 A control box 5 is arranged on the top, and a conveying housing 6 is provided on one side of the stacker 4, and a conveyor belt 7 is provided inside the conveying casing 6. A frame body 12 is provided above the conveyor belt 7, and a frame body 12 is provided above the conveyor belt 7. Connected with the conveying housing 6, one side of the conveying housing 6 is provided with a chute 15, the chute 15 is provided with a slider 14, the other end of the slider 14 is connected with a fixed block 8, the The slide block 14 is matched and slidably connected with the chute 15, and the fixed block 8 is provided with a threaded rod 9, one side of the threaded rod 9 is connected with a motor 10, and the motor 10 drives and connects the threaded rod 9, a...

Embodiment 3

[0057] Such as Figure 5-6 As shown, on the basis of the second embodiment, the mechanical gripper 11 includes a first rotating shaft 111, the bottom of the first rotating shaft 111 is connected to the fixed block 8, and a second rotating shaft is connected above the first rotating shaft 111 112, the second rotating shaft 112 is connected with the main arm 118, the other end of the main arm 118 is connected with the third rotating shaft 113, the other side of the third rotating shaft 113 is connected with the fourth rotating shaft 11414, the first The four rotating shafts 11414 are connected with the big arm 119, the other end of the big arm 119 is connected with the fifth rotating shaft 115, the fifth rotating shaft 115 is connected with the small arm 120, and the other end of the small arm 120 is connected with the sixth rotating shaft 116, so The other side of the sixth rotating shaft 116 is connected with an adjusting arm 121, and the other end of the adjusting arm 121 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com