Production method of heat-insulating brick by reusing spoil

A production method and brick-laying technology, which are applied in the field of building brick-laying, can solve the problems of brick-laying production quality and inferior brick quality, and achieve the effects of ensuring production quality, slowing down temperature transfer and dissipation, and reducing building energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

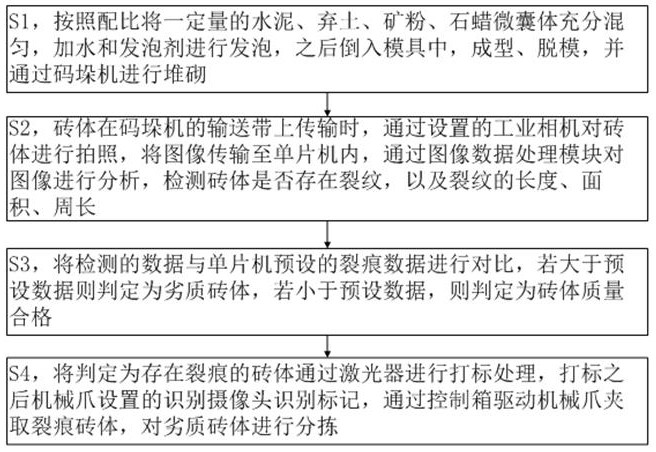

[0058] Such as Figure 11 As shown, a production method for reusing spoil to heat-preserve bricks comprises the following steps: S1, fully mix a certain amount of cement, spoil, mineral powder and paraffin microcapsules according to the ratio, add water and foaming agent Foaming, then pouring into the mold, forming, demoulding, and stacking by palletizer;

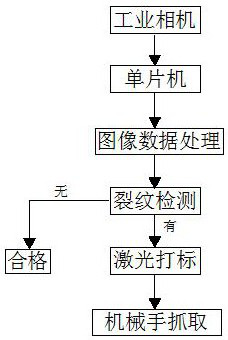

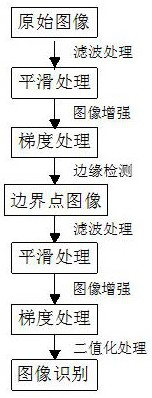

[0059] S2, when the brick body is transported on the conveyor belt of the palletizer, take pictures of the brick body through the set industrial camera, transmit the image to the single-chip microcomputer, analyze the image through the image data processing module, and detect whether there is a crack in the brick body, And the length, area and perimeter of the crack;

[0060] S3, comparing the detected data with the preset crack data of the single-chip microcomputer, if it is greater than the preset data, it is judged as a poor-quality brick body, and if it is less than the preset data, it is judged that the brick body qua...

Embodiment 2

[0069] Such as figure 1 as shown,

[0070] A kind of thermal insulation bricklaying produced by the production method of thermal insulation bricklaying using spoil, comprising a skeleton layer 1, an energy storage layer 2, and a thermal insulation layer 3; the skeleton layer 1 includes an upper skeleton layer 1a and a lower skeleton layer 1b, and the skeleton layer Layer 1 is made of recovered spoil mixed with hard particles, and an energy storage layer 2 is arranged between the upper skeleton layer 1a and the lower skeleton layer 1b, and the energy storage layer 2 is made of energy storage materials and mixed The upper surface of the energy storage layer 2 is bonded to the upper skeleton layer 1a, and the lower surface of the energy storage layer 2 is bonded to the lower skeleton layer 1b; the energy storage layer 2 At the central position, an insulating layer 3 is bonded horizontally, and the upper skeleton layer 1a, the lower skeleton layer 1b, the energy storage layer 2,...

Embodiment 3

[0075] Such as Figure 2-4 As shown, a production device for reusing waste soil and heat preservation brick laying used in a production method of waste soil reuse heat preservation brick laying includes a mechanical module and a detection module, the mechanical module includes a palletizer 4, and the palletizer The machine 4 is provided with a control box 5, and one side of the stacker 4 is provided with a conveying housing 6, and the inside of the conveying housing 6 is provided with a conveyor belt 7, and a frame body 12 is provided above the conveyor belt 7, and the frame The body 12 is connected with the conveying shell 6, and one side of the conveying shell 6 is provided with a chute 15, and a slide block 14 is arranged in the chute 15, and the other end of the slide block 14 is connected with a fixed block 8, The slider 14 is matched and slidably connected with the chute 15, the fixed block 8 is provided with a threaded rod 9, one side of the threaded rod 9 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com