Embedded planetary speed reducing mechanism

A planetary deceleration and embedded technology, which is applied to clockwork mechanisms, mechanical equipment, vehicle gearboxes, etc., can solve problems such as changing the lifting speed, limited transmission ratio improvement, and self-heavy mass, so as to increase the load and increase the transmission ratio , compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

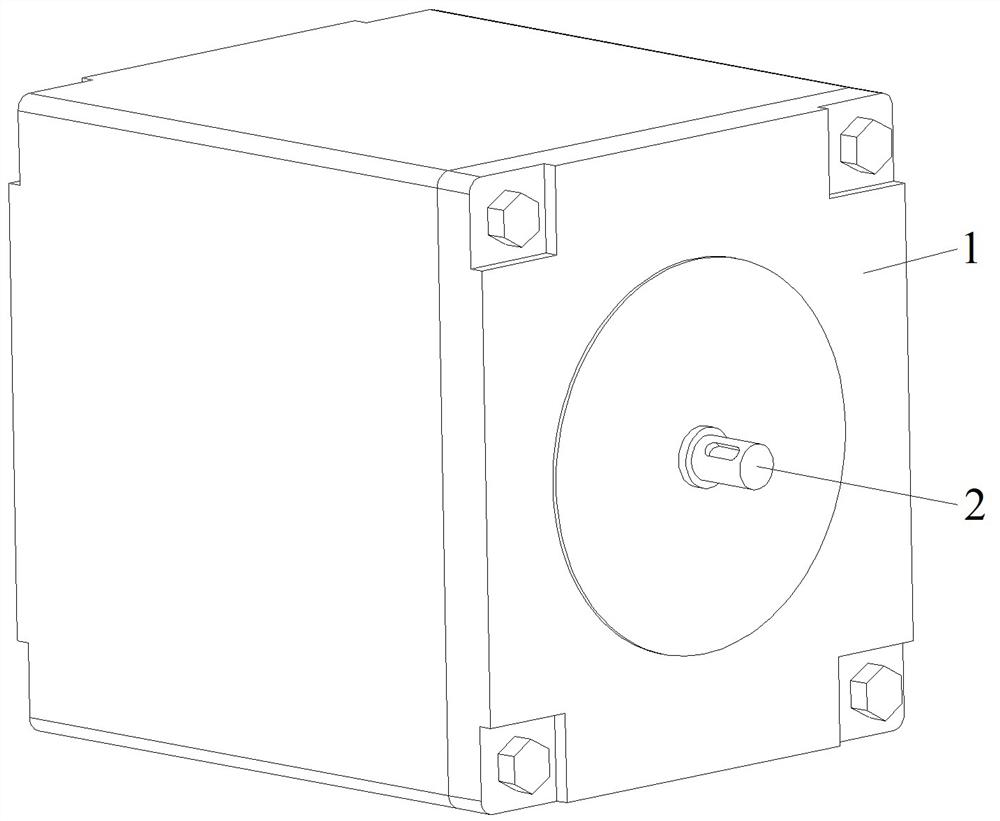

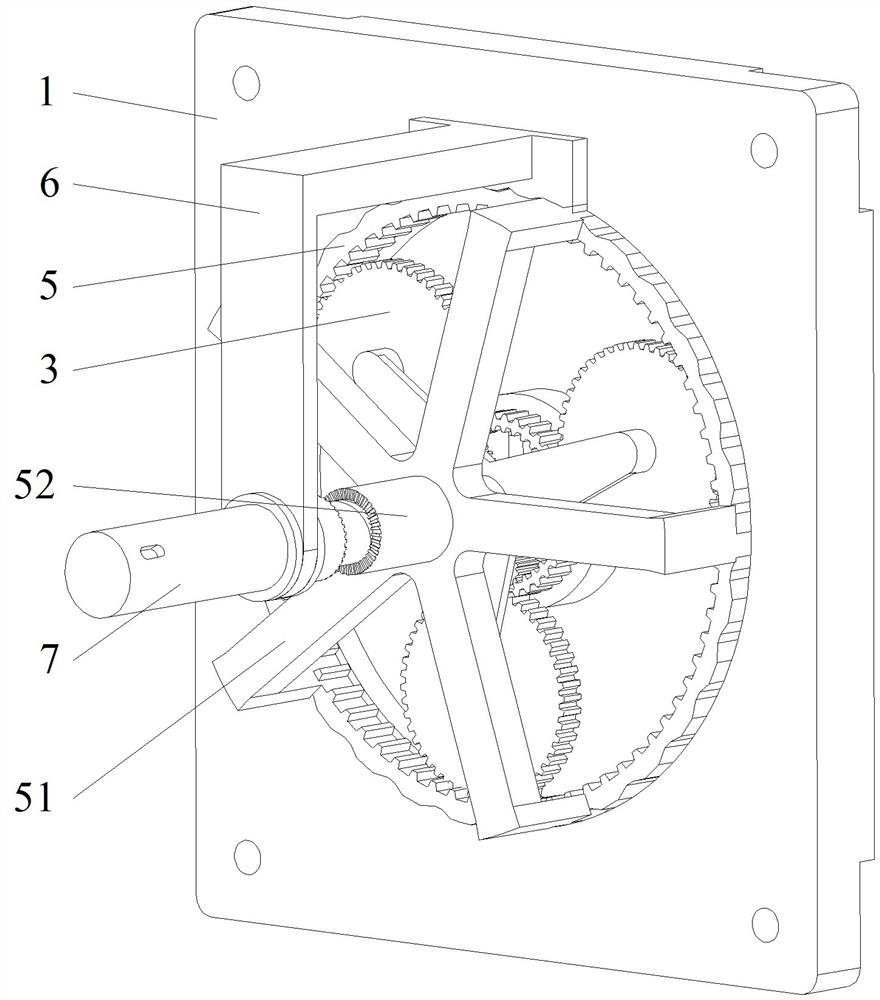

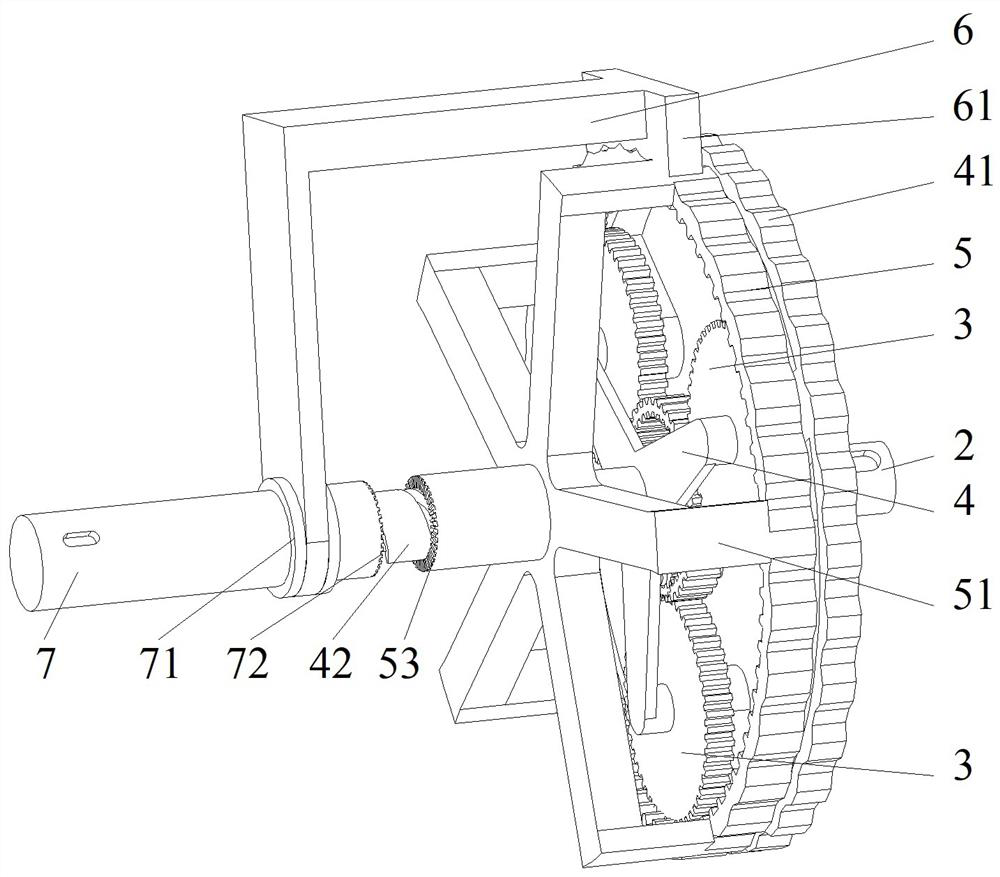

[0047] Such as Figure 1-14 The shown embodiment of the present invention is an embedded planetary reduction mechanism, which includes a housing 1, a sealing groove 12, a chute 11, and a planetary groove 13 are arranged on the housing 1, and the primary planetary gear is arranged in the housing 1 gear train and secondary planetary gear train;

[0048] The primary planetary gear system includes planetary gear Ⅱ3, planetary carrier Ⅱ4, ring gear 5, and input ring gear 22, wherein the input ring gear 22 is the sun gear of the primary planetary gear system, and planetary carrier Ⅱ4 includes planetary gear 41, planetary output shaft 42;

[0049] The planetary output shaft 42 is pivotally connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com