Novel EGR corrugated pipe suitable for high temperature and provided with composite layer flow guide pipe structure

A technology of composite layer and diversion pipe, which is applied in the direction of pipes/pipe joints/fittings, expansion compensation devices for pipelines, pipe components, etc., which can solve problems such as root fractures between flanges and pipes, and reduce thermal stress , the service life is improved, and the effect of ensuring high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

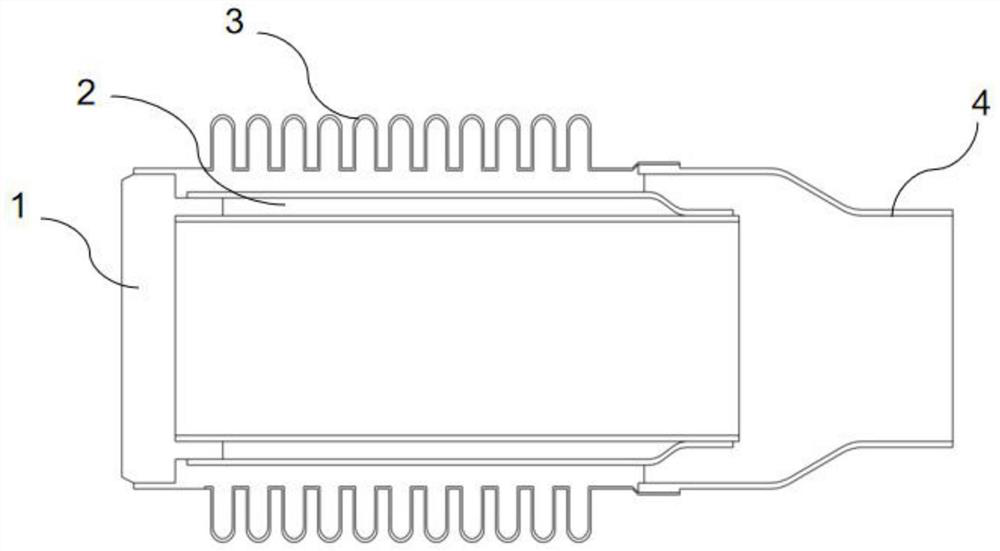

[0034] See figure 1 , a new type of EGR corrugated pipe with a composite layer guide pipe structure suitable for high temperature includes: a flange 1, a composite layer guide pipe 2, a multilayer corrugated pipe 3, and a straight pipe 4. The straight pipe 4 can be arranged according to actual needs, and the straight pipe 4 can also be replaced by an elbow or the straight pipe 4 can be removed to directly connect to the second flange.

[0035] The flange 1 and the straight pipe 4 are respectively arranged at both ends of the new EGR bellows structure;

[0036] One end of the multilayer bellows 3 is connected to the flange 1, and the other end is connected to the straight pipe 4;

[0037] The composite layer diversion pipe 2 is formed by nesting two pipes of different specifications to form a medium-vacuum closed structure, one end of which is connected to the flange 1, and the other end is inserted into the inside of the straight pipe 4 without welding;

[0038] The number o...

Embodiment 2

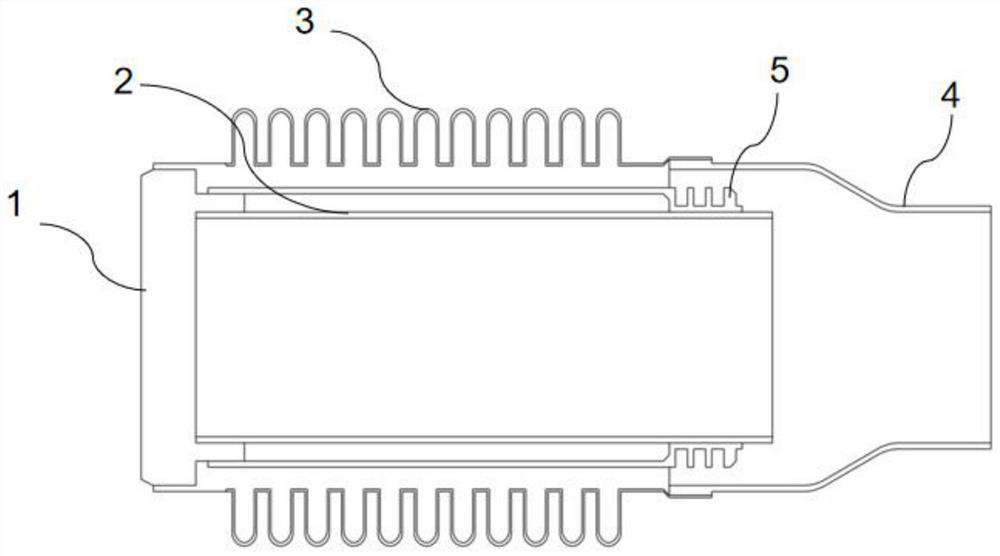

[0043] See figure 2 , a new type of EGR corrugated pipe with a composite layer guide pipe structure suitable for high temperature includes: a flange 1, a composite layer guide pipe 2, a multilayer corrugated pipe 3, and a straight pipe 4. Straight pipe 4 also can be bent pipe according to actual needs or removes straight pipe 4 and directly connects flange.

[0044] The flange 1 and the straight pipe 4 are respectively arranged at both ends of the new EGR bellows structure;

[0045] One end of the multilayer bellows 3 is connected to the flange 1, and the other end is connected to the straight pipe 4;

[0046] Composite layer diversion pipe 2 is nested by two kinds of pipes of different specifications, forming a real An empty closed structure, one end of which is connected to the flange 1, and the other end is inserted into the inside of the straight pipe 4 without welding;

[0047] The outer end of the composite layer guide tube 2 located in the straight tube 4 is provided...

Embodiment 3

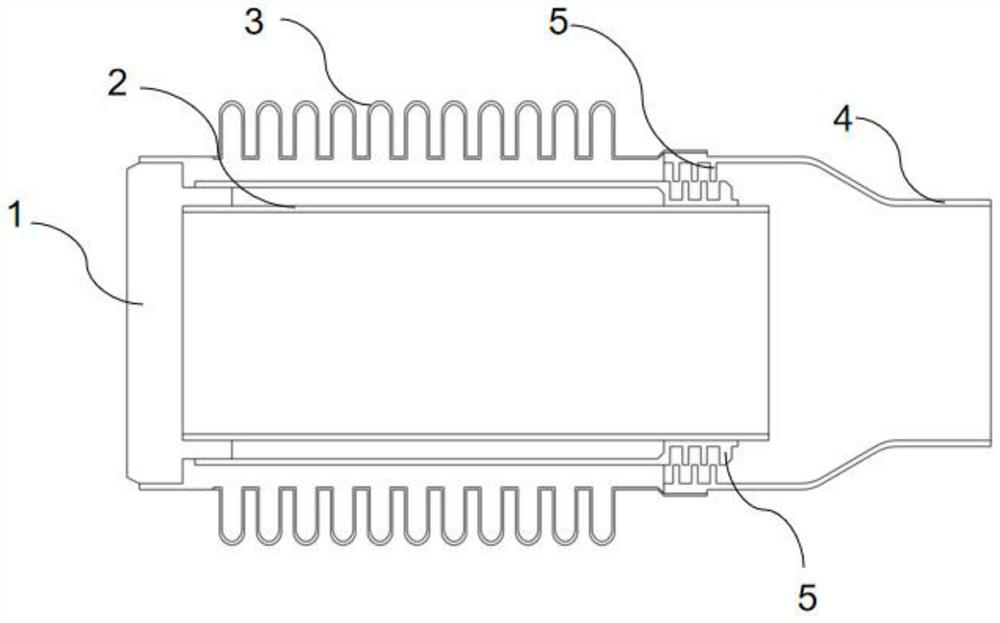

[0053] See image 3 , a new type of EGR corrugated pipe with a composite layer guide pipe structure suitable for high temperature includes: a flange 1, a composite layer guide pipe 2, a multilayer corrugated pipe 3, and a straight pipe 4. Straight pipe 4 also can be bent pipe according to actual needs or removes straight pipe 4 and directly connects the second flange.

[0054] The flange 1 and the straight pipe 4 are respectively arranged at both ends of the new EGR bellows structure;

[0055] One end of the multilayer bellows 3 is connected to the flange 1, and the other end is connected to the straight pipe 4;

[0056] The composite layer diversion pipe 2 is formed by nesting two pipes of different specifications to form a medium-vacuum closed structure, one end of which is connected to the flange 1, and the other end is inserted into the inside of the straight pipe 4 without welding;

[0057] Composite layer guide pipe 2 is located on the outside of the end of straight pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap