Chromatographic material and preparation method thereof, micro chromatographic column and coating method thereof, and micro gas chromatograph

A chromatographic material and chromatographic column technology, applied in the direction of material separation, analysis materials, separation methods, etc., can solve the problems of separation effect and separation ability improvement, and achieve the effect of improving chromatographic separation performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

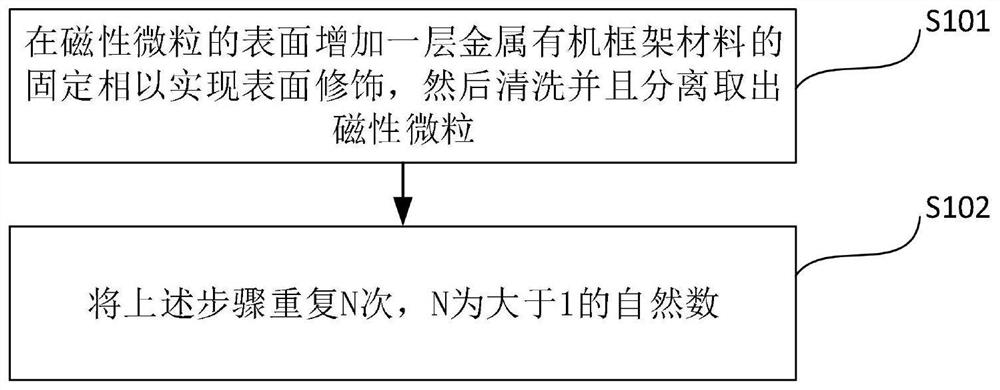

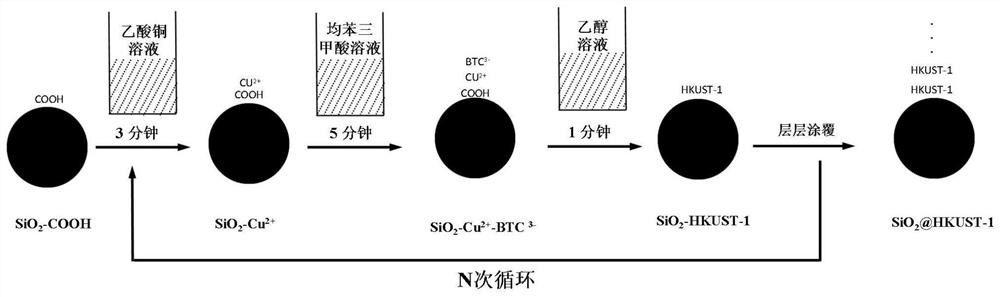

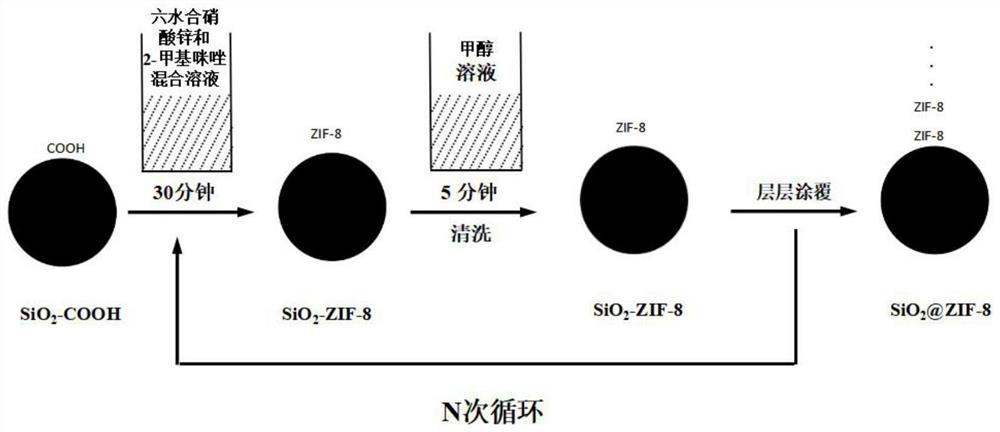

[0033] Metal Organic Framework (MOF) material is a kind of coordination polymer that has developed rapidly in recent years. Generally, metal ions or metal clusters are used as connection points to form a three-dimensional porous structure through self-assembly of organic ligands. It is a kind of New porous materials with broad applications in catalysis, energy storage, and separations. At present, MOF has become an important research direction in many chemical branches such as inorganic chemistry and organic chemistry. In the embodiment of the present invention, magnetic particles are introduced as the stationary phase carrier, and the MOF material is modified on the surface by layer-by-layer coating (Layer-by-Layer) method, and finally the chromatogram of the multilayer MOF stationary phase is obtained. Materials, so that the contact area between the gas and the stationary phase can be greatly increased during the chromatographic separation process, thereby improving the sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com