Novel flexible rollable silicon-based solar module welding method

A welding method and solar technology, applied in the field of solar modules, can solve the problems of low automation, affecting the quality of finished products, affecting production capacity, etc., and achieve the effects of simplifying the production process, reducing the probability of broken, and reducing production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

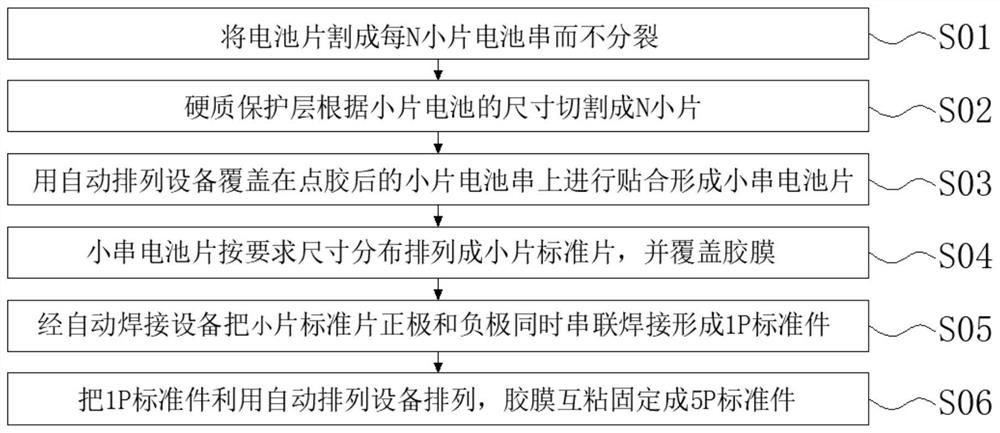

[0039] refer to Figure 1-Figure 9 , a novel flexible and rollable silicon-based solar module welding method, said method comprising the steps of:

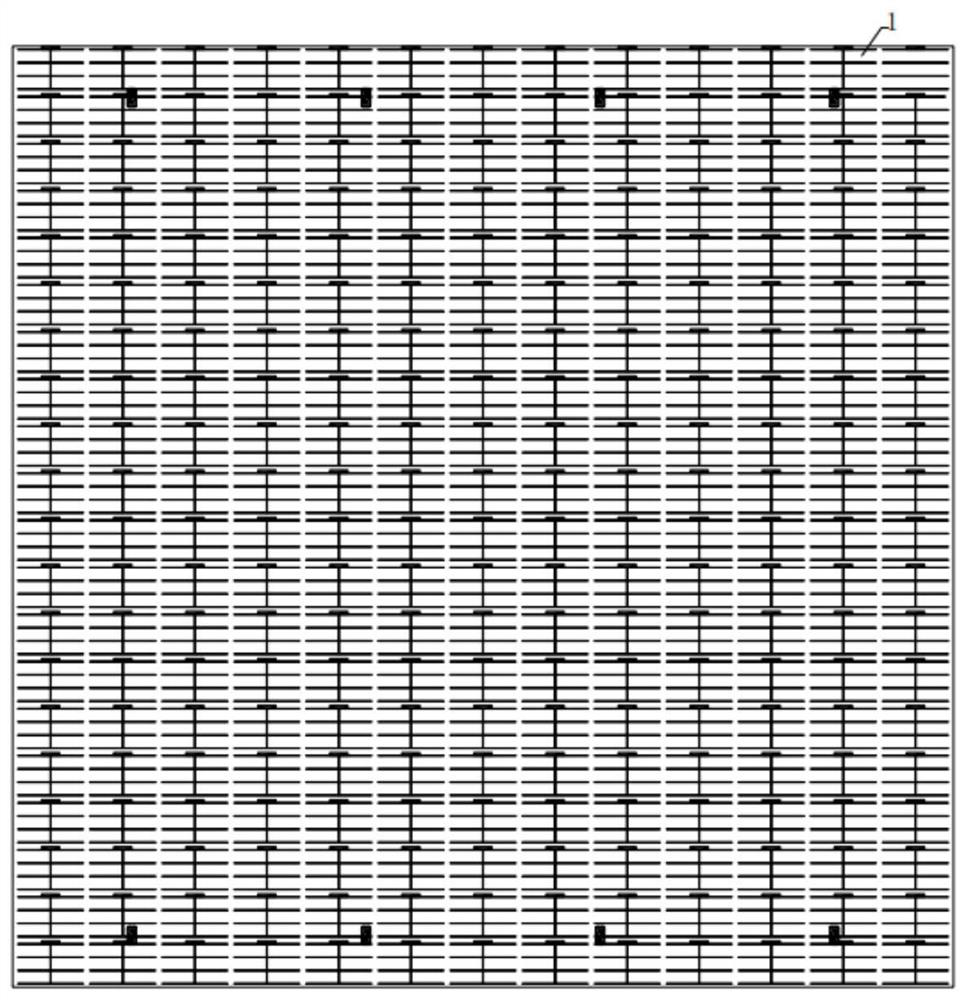

[0040] S01. Provide silicon-based heterojunction solar cells 1. Cut the cells 1 into 13 small cell strings 2 without splitting by laser cutting. Each small cell 3 has a length of 12mm and a width of 7.84mm, and a small cell 3 The positive and negative poles of the battery are arranged at one end of the front and back of the battery, and the negative solder joints are opposite or directly below the positive solder joints;

[0041] S02, the transparent glass 4 is cut into 13 small pieces according to the size of the small battery 3;

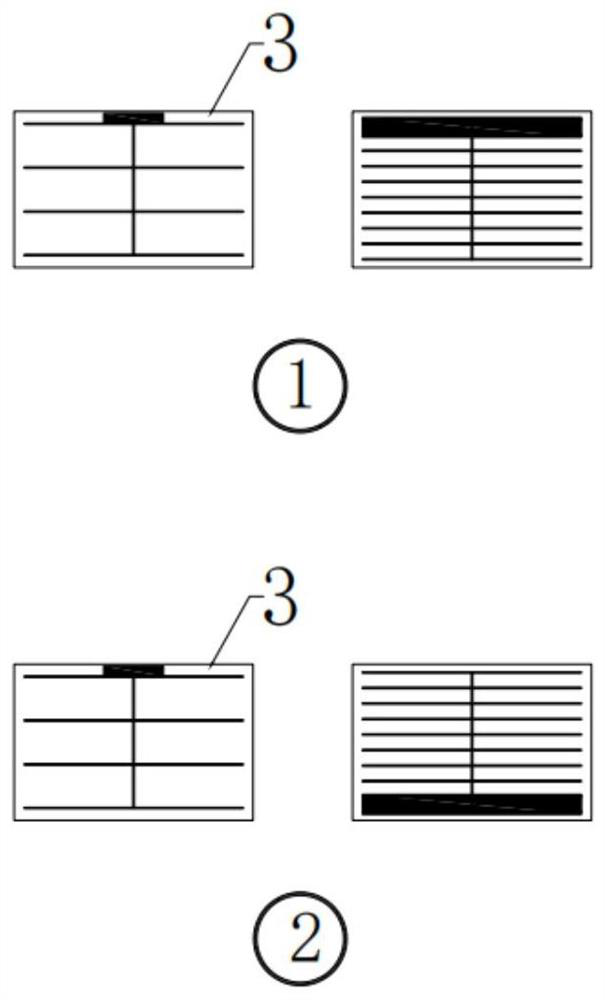

[0042] S03. The cut transparent glass 4 is covered on the small battery string 2 after glue dispensing by an automatic alignment device to form a small battery string 5;

[0043] S04, the small series of battery sheets 5 are arranged according to the required size distribution into small standard she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com