Sodium-lithium battery

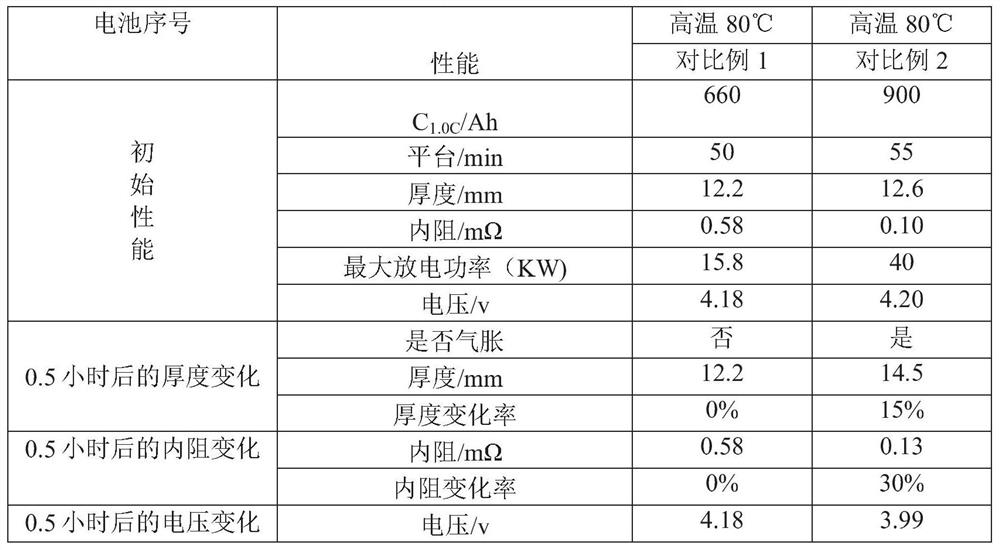

A battery and sodium salt technology, applied in the field of sodium-lithium batteries, can solve the problems of high temperature resistance and poor safety of lithium batteries, and achieve the effects of high temperature resistance, high safety, and high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

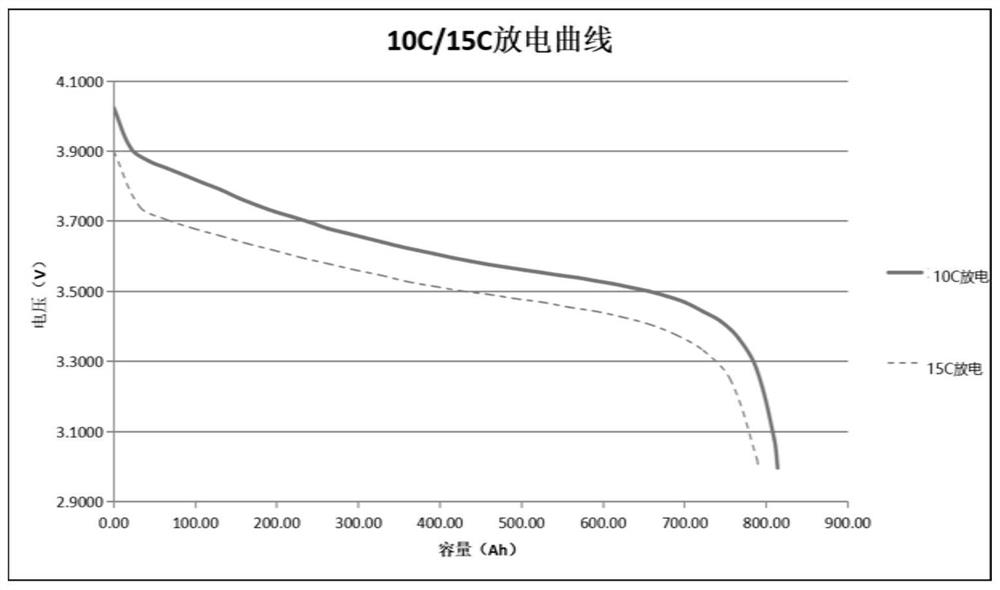

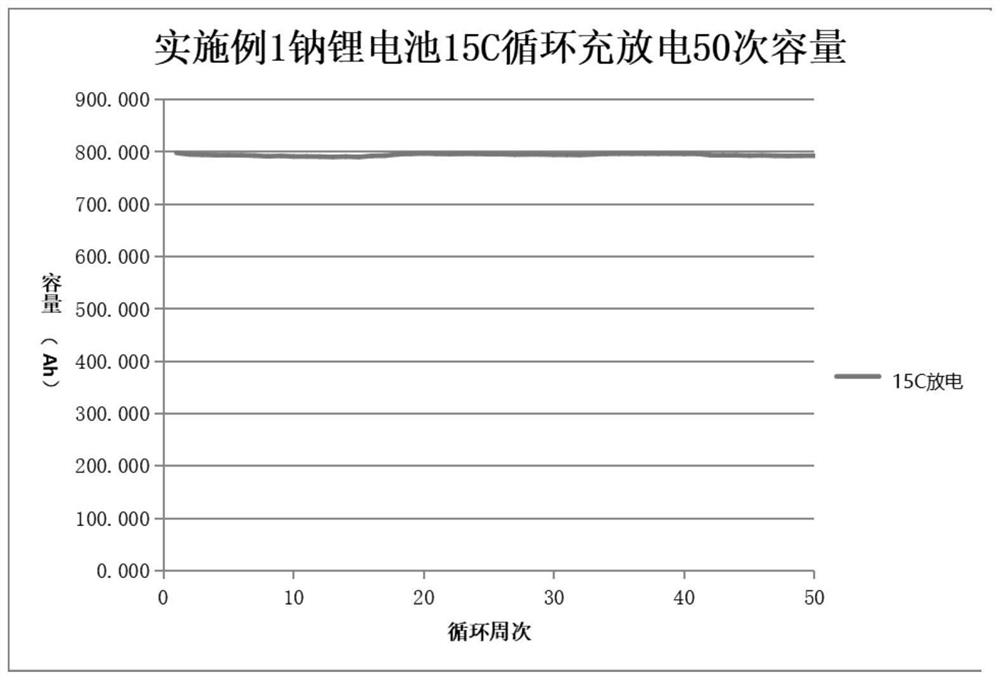

[0056] Embodiment 1: Na-lithium battery

[0057] 1. Composition of Na-Li battery

[0058] The high-power sodium-lithium battery consists of a positive electrode, a negative electrode, a separator, an electrolyte, and a flexible package. It is a soft-packed square battery; calculated based on the total mass of the positive electrode, the positive electrode is composed of 92wt% nickel-cobalt sodium manganate and nickel-cobalt lithium manganate mixture, 4wt % of conductive graphite and 4wt% PVDF, the mass ratio of sodium nickel cobalt manganate and lithium nickel cobalt manganate in the mixture of sodium nickel cobalt manganate and lithium nickel cobalt manganate is 51:49, and the negative pole is 95wt% hard carbon Composed of 2wt% conductive graphite and 3wt% PVDF, the diaphragm is PE with a thickness of 25 microns, the capacity is 800Ah, and the maximum power is 30kW.

[0059] The electrolyte is composed of solvent, sodium salt, lithium salt and additives. Based on the total ...

Embodiment 2

[0065] Embodiment 2: Na-lithium battery

[0066] 1. Composition of Na-Li battery

[0067] The high-power sodium-lithium battery consists of a positive electrode, a negative electrode, a separator, an electrolyte, and a flexible package. It is a soft-packed square battery; calculated based on the total mass of the positive electrode, the positive electrode is composed of 92wt% nickel-cobalt sodium manganate and nickel-cobalt lithium manganate mixture, 4wt % of conductive graphite and 4wt% PVDF, the mass ratio of nickel-cobalt-sodium manganate and nickel-cobalt-lithium manganate in the mixture of nickel-cobalt-manganate-sodium-nickel-cobalt-manganate and nickel-cobalt-lithium-manganate-lithium is 75:25, and the negative pole is 95wt% hard carbon It is composed of 2wt% conductive graphite and 3wt% PVDF; the negative electrode is hard carbon, the separator is PE with a thickness of 25 microns, and the capacity is 600Ah.

[0068] The electrolyte is composed of solvent, sodium lith...

Embodiment 3

[0073] Embodiment 3: Na-lithium battery

[0074] 1. The composition of sodium-lithium battery

[0075] The high-power sodium-lithium battery consists of a positive electrode, a negative electrode, a separator, an electrolyte, and a flexible package. It is a soft-packed square battery; calculated based on the total mass of the positive electrode, the positive electrode is composed of 92wt% nickel-cobalt-manganese-aluminate and nickel-cobalt-lithium manganate mixture. Composed of 4wt% conductive graphite and 4wt% PVDF, the mass ratio of nickel-cobalt-manganese-aluminate sodium and nickel-cobalt-lithium manganate in the mixture of nickel-cobalt-manganese-aluminate and nickel-cobalt-lithium manganate is 75:25, and the negative pole is 95wt % hard carbon and 2wt% conductive graphite and 3wt% PVDF, the diaphragm is PE with a thickness of 25 microns, and the capacity is 600Ah.

[0076] The electrolyte is composed of solvent, sodium lithium salt and additives. Based on the total mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com