Method for carbon source replacement for denitrification process in wastewater treatment

A carbon source and wastewater technology, applied in the adjustment method of biological treatment, natural water body treatment, water treatment parameter control and other directions, can solve the problems of microbial viability and activity effect, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Different turnover percentages were compared during the carbon source change from ethylene glycol (EG) to glucose. In Trial 1, the glucose percentage was initially increased by 10%, eg 10%, 20%, 30%, 40% and 50%, and maintained for 10 days after each replacement. The glucose percentage is then increased faster than the start, eg 70%, 90% and 100%, and each increase also runs steadily for 10 days. During test 1, the denitrification performance was good and stable, and the outlet TN was less than 20mg / L. In experiment 2, the replacement speed was faster than experiment 1, and the percentage of glucose was set to 20%, 40%, 60%, 80%, 100%, and each time was kept for 10 days, and the denitrification was found to be unstable, and the outlet TN exceeded 70mg many times / L (standard: 45mg / L). The mixture of ethylene glycol (EG) and glucose had a ratio of total COD to total nitrogen in the wastewater of 3.5 in the test.

[0060] Table 1 Comparison of the second carbon source ...

Embodiment 2

[0063] In order to examine the effect of the duration after each increase in the replacement carbon percentage, trials 3, 4, and 5 were carried out, with durations of 20 days, 5 days, and 30 days, respectively. In Experiment 3, the denitrification performance was good and stable, similar to Experiment 1 (10 days). In Trial 4, the outlet TN was higher than 50 mg / L several times due to the short run time (only 5 days) after the percentage conversion was increased. In Trial 4, no improvement in denitrification performance was seen after extending to 30 days, consuming a longer time. According to comparative experiments, it is recommended to choose 10-20 days as the maintenance time. In the test, the ratio of the total chemical oxygen demand of the mixture of ethylene glycol (EG) and glucose to the total amount of nitrogen in the wastewater was 3.5.

[0064] Table 2 Comparison of the duration of each displacement

[0065]

Embodiment 3

[0067] To investigate the effect of COD / TN ratio on nitrogen removal performance during carbon source switching from ethylene glycol (EG) to glucose, the first experiments were performed in beakers under the condition that 50% of the first carbon source was replaced. The same sludge was added to seven 1.0L beakers to prepare 1000mg / L initial TN and carbon source was added, COD / TN weight ratio (g / g) was 2.0, 3.0, 3.5, 4.0, 4.5, 5.0. Samples were taken from the beaker every 4 hours and analyzed for COD and TN.

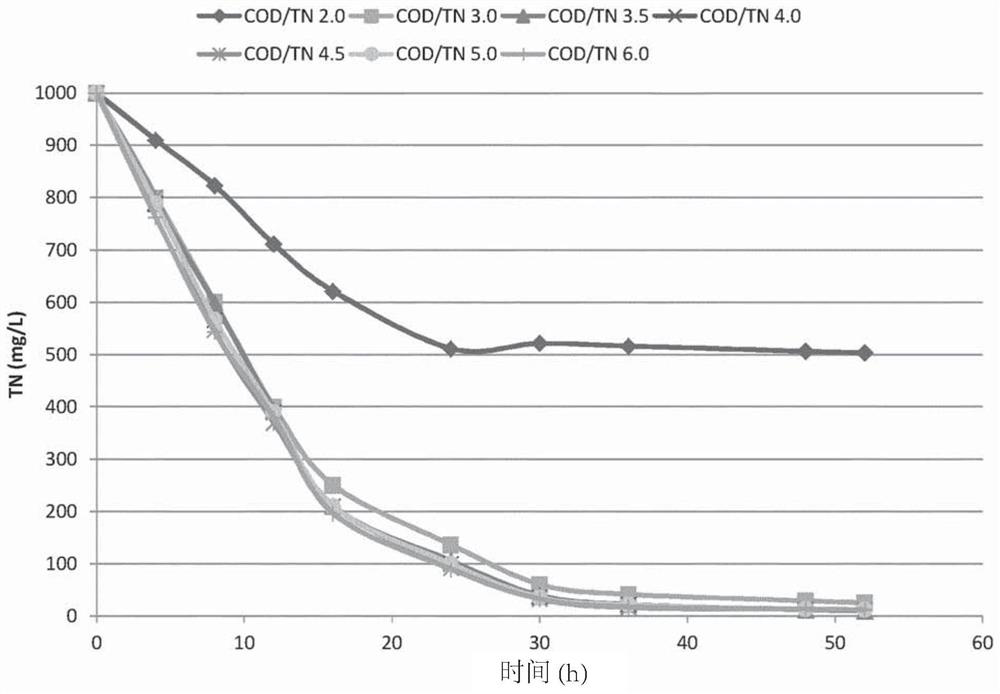

[0068] ·TN removal

[0069] COD / TN = 2.0, TN removal is not complete, outlet TN ~ 500mg / L, when the COD / TN ratio is 3.0, 3.5, 4.0, 4.5, 5.0 and 6.0, the final TN is ~ 20mg / L, see figure 1 .

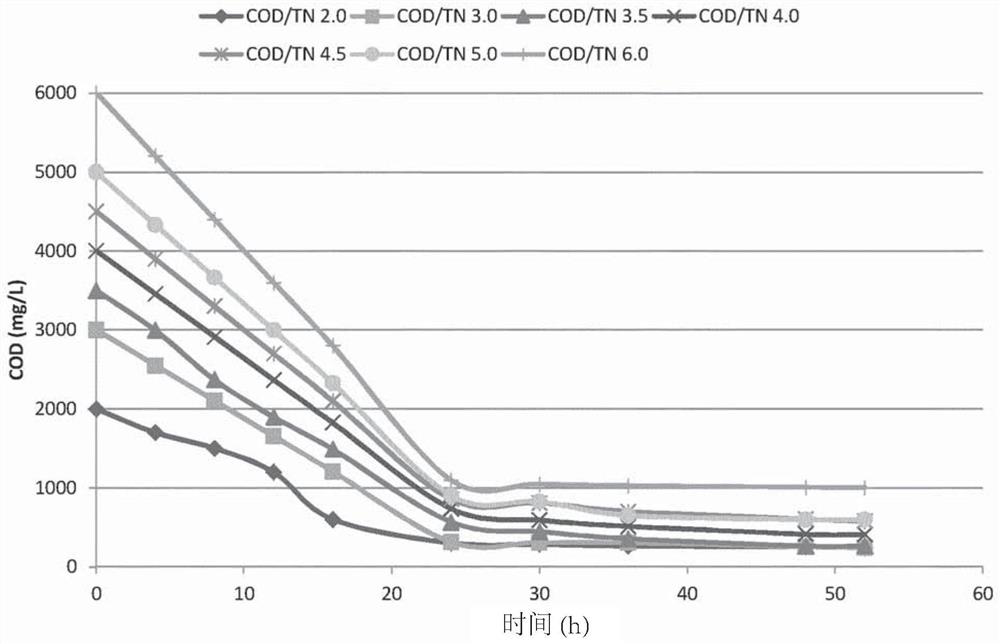

[0070] · Residual carbon (COD)

[0071] With the increase of COD / TN, the residual COD will increase. When COD / TN=6.0, the residual COD in the outlet wastewater is greater than 1000mg / L. When COD / TN=2.0, 3.0, 3.5, 4.0, 4.5, 5.0, 6.0, the final COD is 246, 245, 266, 409, 579, 599...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com