Heat accumulating type steel rolling heating furnace low-temperature flue gas desulfurization and denitrification system and method

A technology for desulfurization and denitrification, low-temperature flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems affecting the use and effect of desulfurization and denitrification, low flue gas temperature, low dew point temperature, etc., to save an investment Cost and running cost, reduction of gas consumption, effect of reduction of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

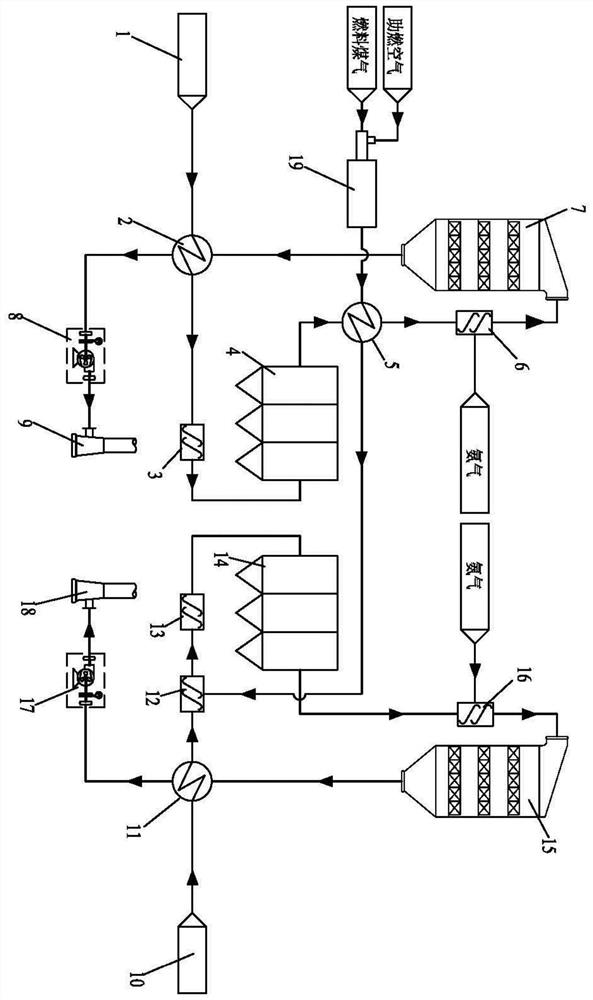

[0052] This embodiment provides a low-temperature flue gas desulfurization and denitrification system of a regenerative steel rolling heating furnace, such as figure 1 As shown, it includes a soot flue gas desulfurization and denitrification device and an air flue gas desulfurization device;

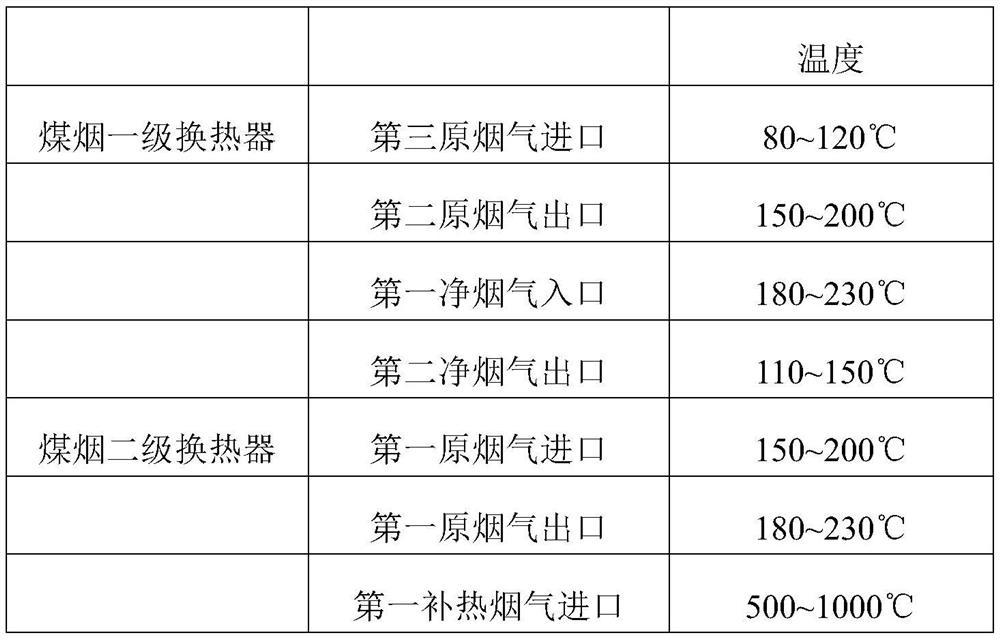

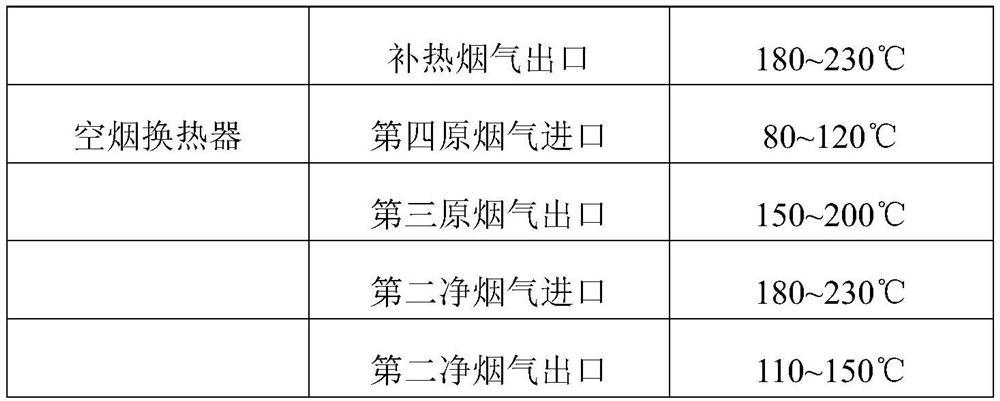

[0053] Specifically, the soot flue gas desulfurization and denitrification device in this embodiment includes a soot dry desulfurization and dust removal mechanism, a soot secondary heat exchanger 5, and a soot SCR denitrification reactor 7 connected in sequence; The pipe 1 communicates with the inlet end of the soot dry desulfurization and dust removal mechanism through the soot primary heat exchanger 2; the soot secondary heat exchanger 5 includes the first raw flue gas inlet, the first raw flue gas outlet, the first supplementary The hot flue gas inlet and the heating flue gas outlet, the first heating flue gas inlet and the heating flue gas supply mechanism are connected through flue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com