Water tank wire drawing machine capable of improving steel wire performance

A water tank wire drawing machine, performance technology, applied in the direction of the wire drawing die, etc., can solve the problems of poor steel wire ring diameter, abnormal use of wire mesh, and ring change, etc., to improve through-tuning, avoid the decline of steel wire surface finish, and reduce the problem of broken wires Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

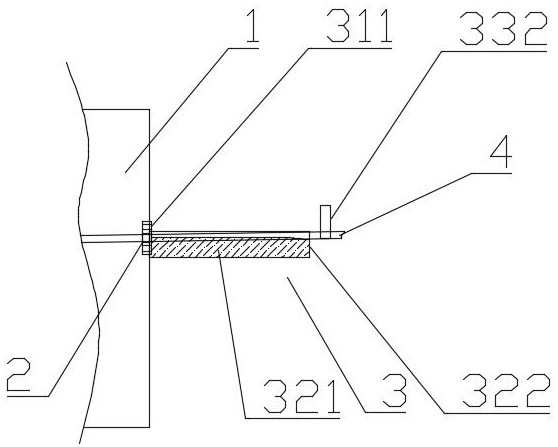

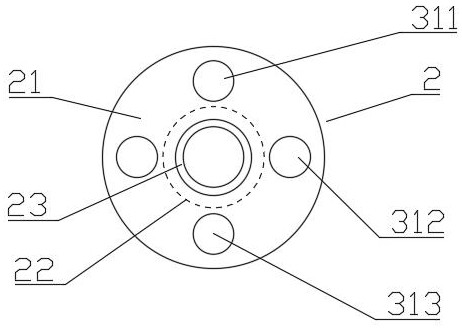

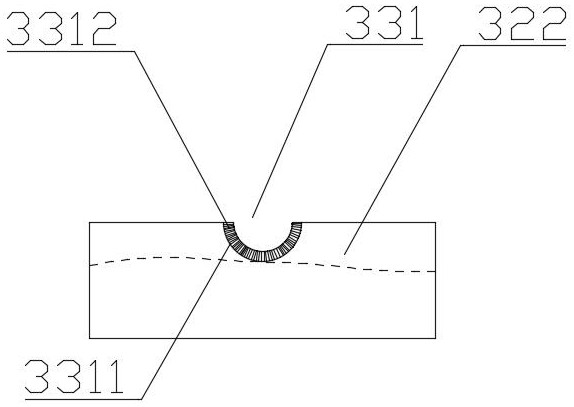

[0022] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a water tank wire drawing machine for improving the performance of the steel wire 4, comprising a water tank wire drawing machine body 1, an adjustable finished product mold 2 is embedded in the exit of the water tank wire drawn machine body 1, and the input end of the adjustable finished product mold 2 is located in the water tank In the wire drawing machine body 1 , the output end of the adjustable finished mold 2 is located outside the water tank wire drawing machine body 1 .

[0023] When the water tank wire drawing machine draws the steel wire 4 step by step, due to the rotation of the motor and other reasons, the finished mold of the steel wire 4 vibrates and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com