Torsional wave ultrasonic vibrator for metal microwire drawing

A technology of ultrasonic vibrators and microwires, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve problems such as low yield, small ring diameter, frequent broken wires, etc. problem, to achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

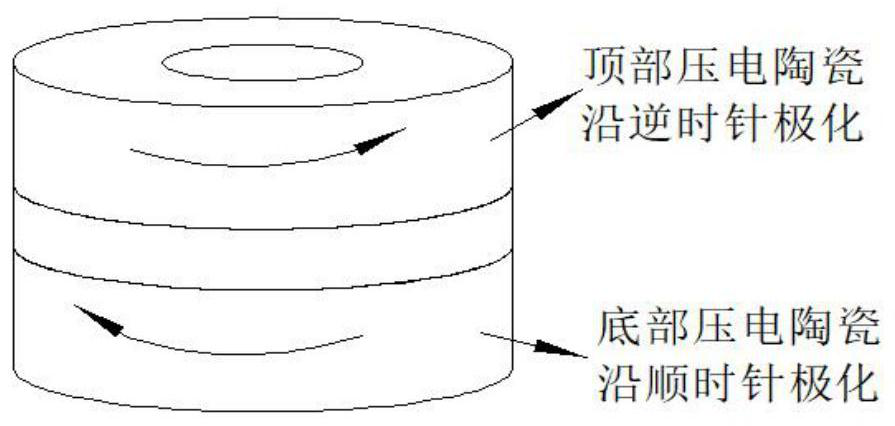

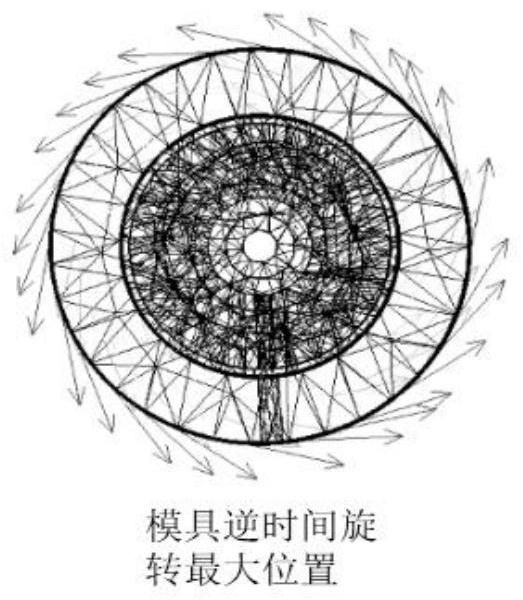

[0048] The piezoelectric ceramic 2 works in the torsional wave resonance mode; when the pulling force is not less than 25N, the two piezoelectric ceramic sheets (2) in the torsional wave ultrasonic vibrator for metal microwire drawing provided by the present invention adopt an amplitude are equal, the frequency is equal to the parallel resonance frequency of the vibrator, and the AC voltage signal is excited, and the inverse piezoelectric effect of the circumferentially polarized piezoelectric ceramic (2) generates high-frequency torsional mechanical vibration, thereby realizing the ultrasonic vibration of the wire drawing die (6), The ultrasonic vibrator works in power bootstrap mode. In the power bootstrap mode, the output power of the ultrasonic vibrator increases automatically as the load increases.

Embodiment 2

[0050] The difference between this implementation case and implementation case 1 is that when the pulling force is not greater than 10N, the excitation frequency of the ultrasonic vibrator is equal to the series resonance frequency of the vibrator, and the ultrasonic vibrator works in a low-voltage driving mode. All the other are identical with embodiment 1. In the low-voltage driving mode, the ultrasonic vibrator can realize large-amplitude ultrasonic vibration output under the driving of high-frequency alternating current with an effective value of only tens of volts.

Embodiment 3

[0052] The difference between this example and Example 1 is that when the pulling force is greater than 10N and less than 25N, the excitation frequency of the ultrasonic vibrator is equal to the average value of the parallel resonant frequency and the series resonant frequency of the vibrator, and the ultrasonic vibrator works in a mixed mode. All the other are identical with embodiment 1. In the hybrid mode, the ultrasonic vibrator takes into account the low-voltage drive characteristics of the series resonance and the power bootstrap characteristics of the parallel resonance.

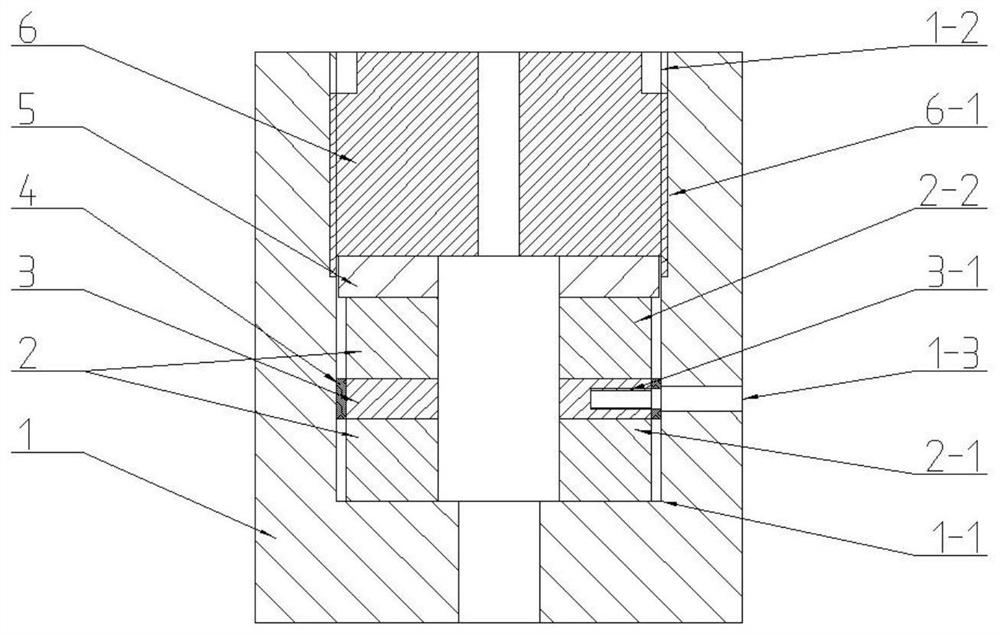

[0053] The torsional wave ultrasonic vibrator used for drawing metal microwires provided by the invention solves the existing problems of low metal microwire drawing yield, poor wire surface quality, and small ring diameter. The vibrator is a half-wavelength longitudinal wave ultrasonic vibrator, and the piezoelectric ceramic sheet 2 is polarized along the circumferential direction; the wire drawing d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com