Special ceramic product polishing machine

A special ceramic and polishing machine technology, applied in the field of polishing, can solve the problems of fixed clamping and inability to realize ceramic products, etc., and achieve the effect of accelerating air flow speed, improving the quality of working environment, and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

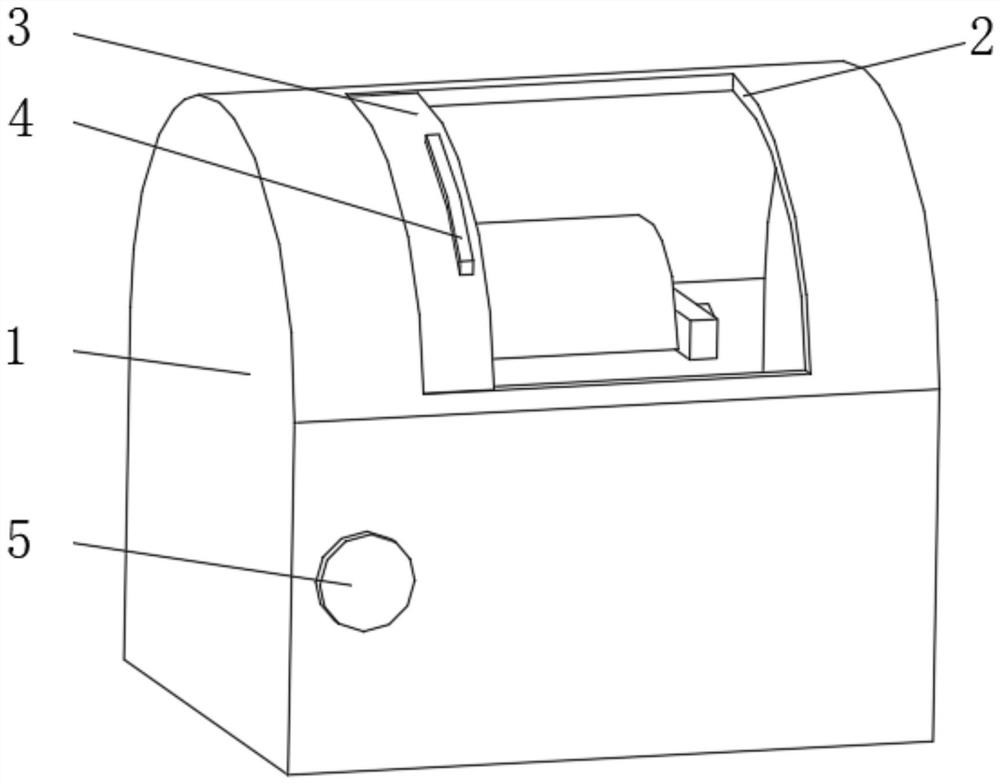

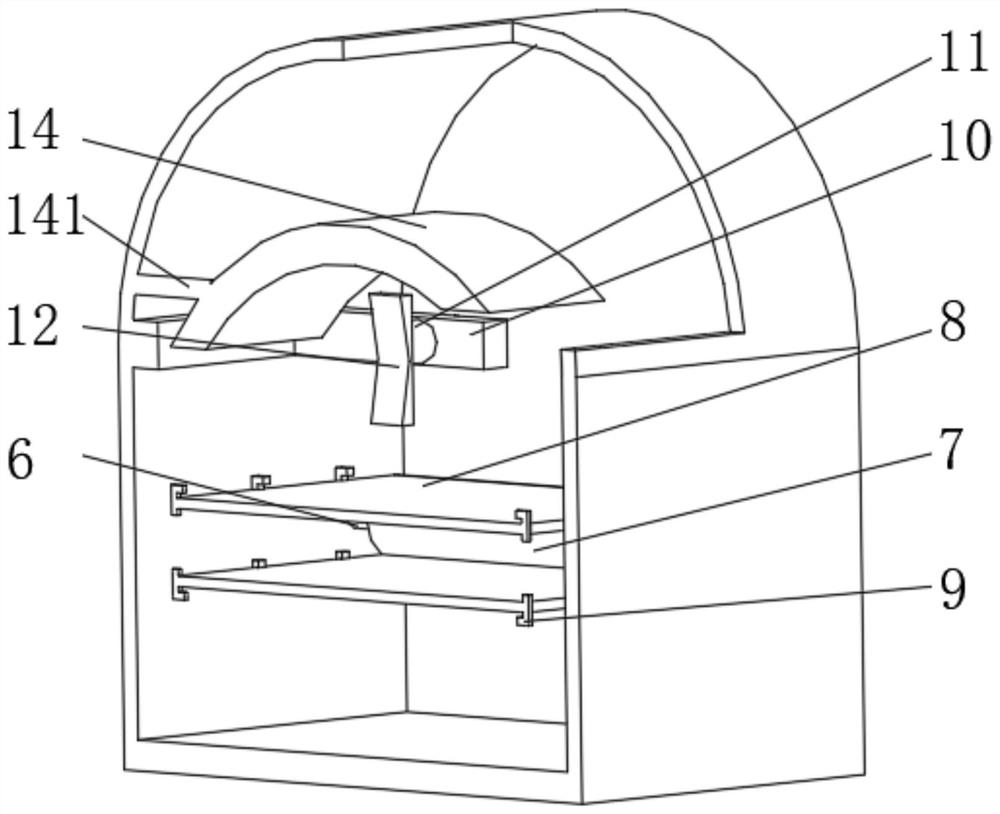

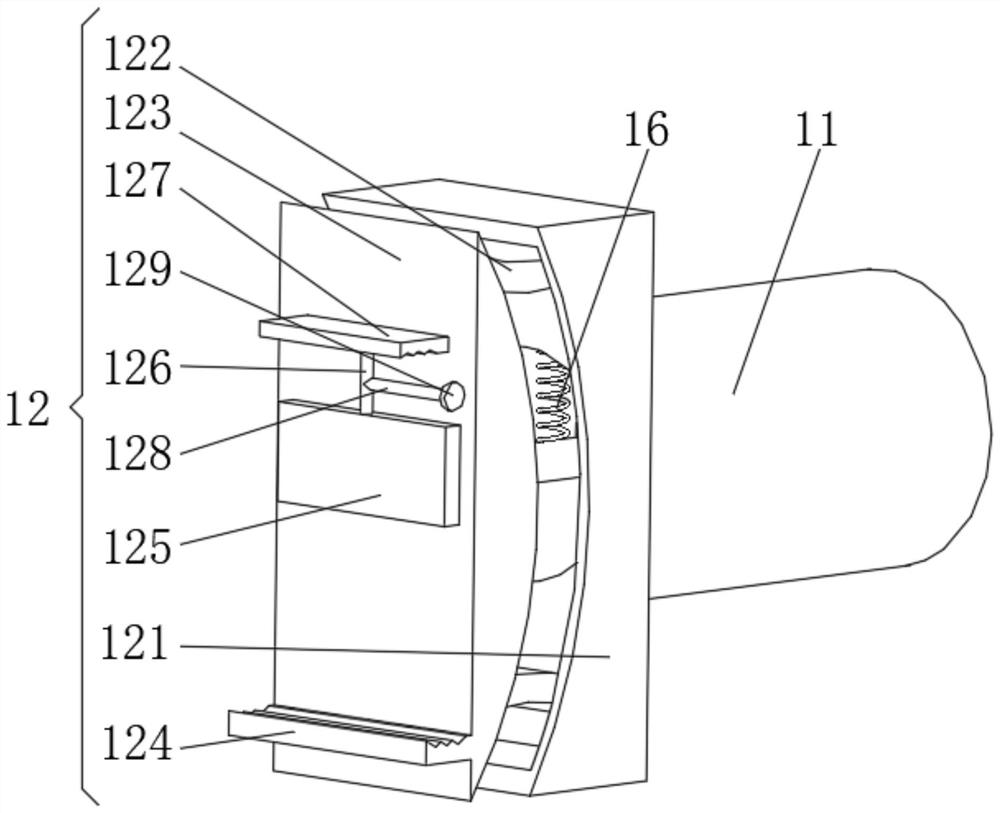

[0029] see Figure 1-4 , the present invention provides a technical solution: a polishing machine for special ceramic products, including a shell 1, characterized in that: one side of the shell 1 is provided with a feed port 2, and one side of the feed port 2 is slidably connected with a sliding door 3 The side of the sliding door 3 away from the shell 1 is fixedly connected with a handle 4, the outside of the shell 1 is fixedly connected with a drive motor 5, the output end of the drive motor 5 is rotatably connected with a rotating rod 6, and one end of the rotating rod 6 runs through the shell 1 and is fixedly connected There is a rolling column 7, the outer side of the rolling column 7 is provided with a rolling belt 8, and one side of the rolling belt 8 is evenly equipped with a buckle 9, and the inner wall of the shell 1 is fixedly connected with a fixed block 10, and one side of the fixed block 10 is fixedly connected with a A cylindrical frame 11 , one side of the cyli...

Embodiment 2

[0037] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a dust suction device 14 is installed on the inner wall of the housing 1, the dust suction device 14 includes a dust discharge pipe 141, and one side of the dust discharge pipe 141 is connected with a dust suction frame 142, the inner wall of the dust discharge pipe 141 is fixedly connected with a rotating motor 143, the output end of the rotating motor 143 is connected with a rotating rod 144, and the end of the rotating rod 144 away from the rotating motor 143 is fixedly connected with a rotating fan blade 145, one of the suction frame 142 The side is connected with a dust inlet pipe 146, and the inner wall of the dust inlet pipe 146 is evenly connected with inclined plates 147, and connecting ropes 148 are connected between the inclined plates 147.

[0038] The side of the inclined plate 147 away from the connecting rope 148 is fixedly connected with an arc-shaped sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com