Application of non-release type antimicrobial adhesion coating in antibacterial pipe

An anti-microbial and adhesion technology, applied in coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve problems such as waste of resources, high reactivity, and complicated operation steps, so as to ensure a smooth structure and prevent The effect of microorganism adhesion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

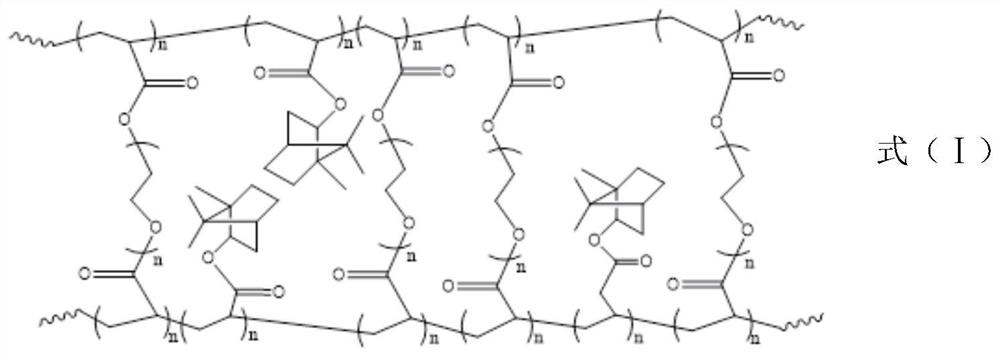

[0041] As mentioned above, in the two methods of preparing polymer antibacterial materials, adding antibacterial ingredients during the preparation process is difficult, and the utilization rate of antibacterial ingredients is not high; after the polymer is processed and formed, antibacterial ingredients are loaded on the surface. There are problems such as the release of antibacterial ingredients, poor persistence of effect, and even the release of antibacterial ingredients that affect the safety of use. In addition, it is difficult to combine resistance to fungi and bacteria in existing antibacterial materials.

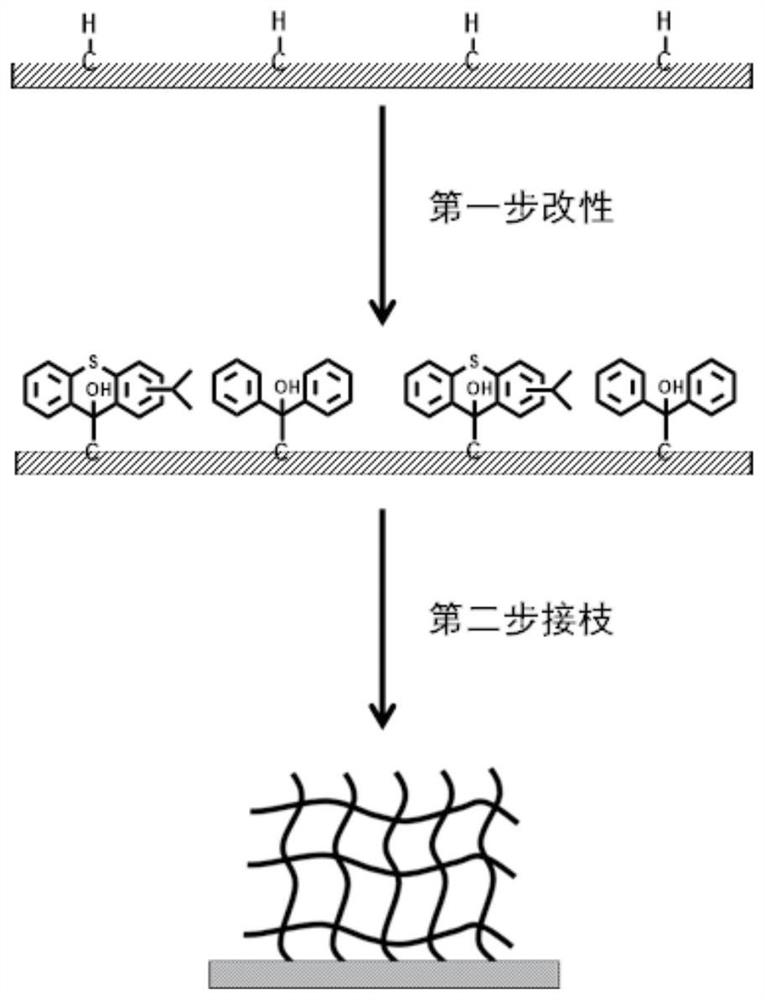

[0042] At present, the research on the antimicrobial properties of borneol only stays in the modification of the substrate by using borneol alone. Although it has a significant antibacterial effect, the photoinitiated polymerization of the borneol acrylate monomer cannot achieve the surface of the grafted material. antibacterial properties. However, the existing gr...

Embodiment 1

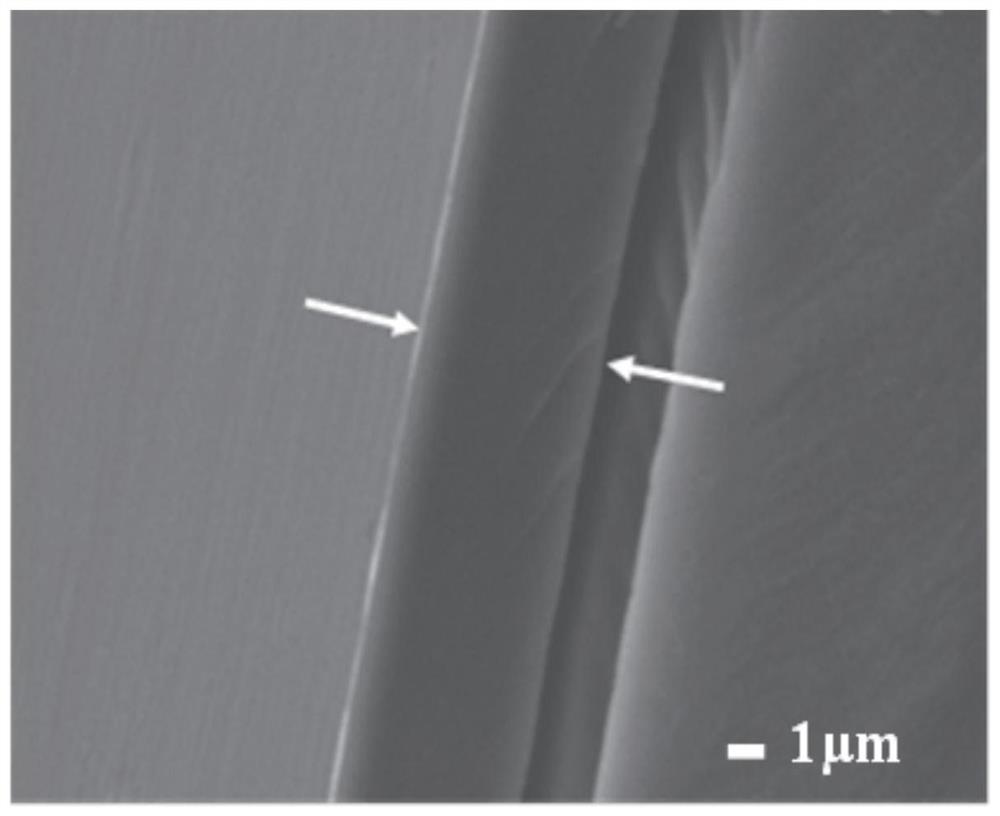

[0099] Grafted PBA-PPEGDA coating preparation of polyacrylonitrile membrane:

[0100] (1) Solution preparation

[0101] Preparation of photoinitiator solution: Weigh 4.2300g of isopropylthioxanthone and 0.6066g of benzophenone in a brown sample bottle, then add 10mL of acetone, vortex, ultrasonic 20min to fully dissolve it, and finally dissolve it Nitrogen blowing apparatus (ND400, Hangzhou Ruicheng Instrument Co., Ltd.) was used to bubble for 20 minutes to fully remove oxygen to obtain a photoinitiator solution.

[0102] Preparation of monomer solution: After mixing 2.08mL BA and 2.00mL PEGDA (relative molecular weight 200) (the molar ratio of BAP to PEGDA is 1:1), draw 0.8mL mixed monomer and 0.2mL acetone into a brown sample Ultrasonic treatment was carried out in the bottle, and then deoxygenated by nitrogen gas for 20 minutes to obtain a monomer solution.

[0103] (2) Preparation of photoinitiator-modified polyacrylonitrile film

[0104] Soak the polyacrylonitrile memb...

Embodiment 2

[0129] Embodiment 2: the grafting PBA-PPEGDA coating preparation of polyethylene film:

[0130] (1) Solution preparation

[0131] Preparation of photoinitiator solution: Weigh 2.5400g of isopropylthioxanthone and 1.8220g of benzophenone in a brown sample bottle, then add 10mL of acetone, vortex, ultrasonic 20min to fully dissolve it, and finally dissolve it Bubble for 20 minutes with a nitrogen blower to fully remove oxygen to obtain a photoinitiator solution.

[0132] Preparation of monomer solution: After mixing 2.08mLBA and 4.00mL PEGDA (relative molecular weight 400) (the molar ratio of BAP to PEGDA is 1:1), draw 0.65mL of mixed monomer and 0.35mL of acetone into a brown sample bottle Ultrasonic treatment was performed, followed by deoxygenation with nitrogen gas for 20 min to obtain a monomer solution.

[0133] (2) Preparation of photoinitiator-modified polyethylene film

[0134] Soak the polyethylene film in acetone for 10 h, and ultrasonically remove impurities for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com