Pretreatment process of high-comfort China-hemp fabric

A pre-treatment and hemp technology, which is applied in the treatment of textile materials, liquid/gas/steam textile material treatment, fiber treatment, etc., can solve the problems of rough hand feeling, rough hand feeling and high hardness of hemp fabric, and achieve improved dissolution Sexuality and chemical reaction performance, reducing high-temperature scouring time, and improving the effect of rough handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

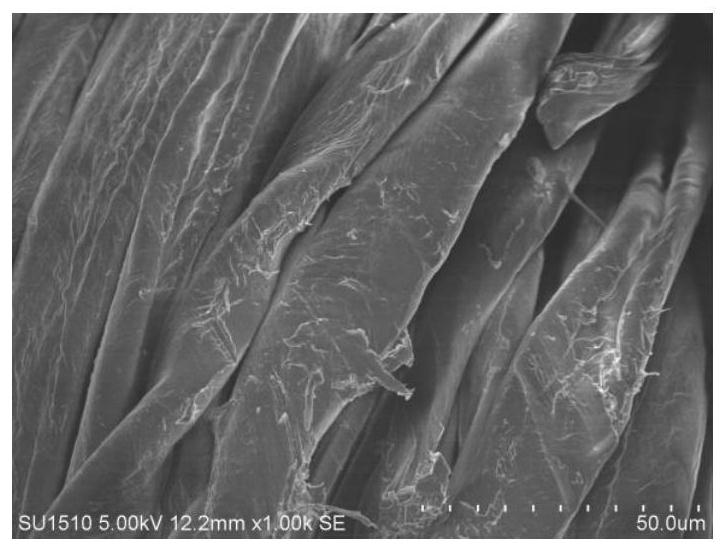

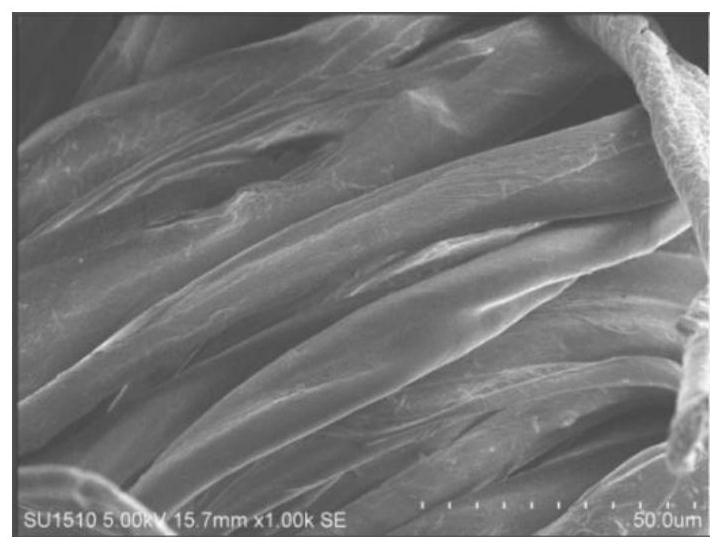

Image

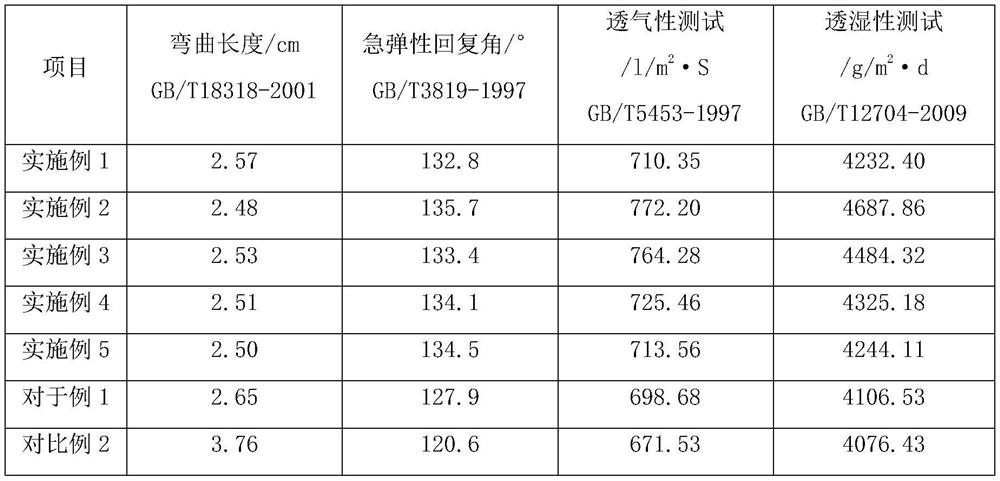

Examples

Embodiment 1

[0025] Embodiment 1: A kind of pretreatment process of high comfort hemp fabric:

[0026] Steam flash explosion scouring and bleaching pretreatment: before the pretreatment, the hemp fabric is dipped in the scouring and bleaching pretreatment liquid (the scouring and bleaching pretreatment liquid includes 30g / l sodium hydroxide, 3g / l penetrating agent JFC, 2g / l scouring aid Sodium bisulfite), with a liquid volume of 120%, and then two-stage steam flash explosion treatment (the hemp fabric is heated and pressurized to 4.2MPa in the steam flash explosion processor, and the pressure is kept for 6s, and then the controlled flash explosion is decompressed to 2.5 MPa, further pressurized for 8s, and then fully flashed to normal pressure), and then taken out for washing and drying.

[0027] Bleaching treatment: the hemp fabric after the steam flash scouring and bleaching pretreatment is completed under the condition of pH=3 to soak the bleaching liquor (sodium chlorite of 15g / l, 10g / ...

Embodiment 2

[0034] Embodiment 2: A kind of high comfort hemp pretreatment process:

[0035] Steam flash explosion scouring and bleaching pretreatment: before the pretreatment, the hemp fabric is dipped in the scouring and bleaching pretreatment liquid (the scouring and bleaching pretreatment liquid includes 20g / l sodium hydroxide, 2g / l penetrating agent JFC, 2g / l scouring aid Sodium bisulfite), with 100% liquid content, and then two-stage steam flash explosion treatment (the hemp fabric is heated and pressurized to 4.2MPa in the steam flash explosion processor, and the pressure is kept for 6s, and then the controlled flash explosion is depressurized to 2.5MPa MPa, further pressurized for 6s, and then fully flashed to normal pressure), and then taken out for washing and drying.

[0036] Bleaching treatment: the hemp fabric after the steam flash scouring and bleaching pretreatment is completed under the condition of pH=5 to soak the bleaching solution (sodium chlorite of 25g / l, ammonium sul...

Embodiment 3

[0039] Embodiment 3: a kind of high comfort hemp pretreatment process:

[0040] Steam flash explosion scouring and bleaching pretreatment: before the pretreatment, the hemp fabric is dipped in the scouring and bleaching pretreatment liquid (the scouring and bleaching pretreatment liquid includes 30g / l sodium hydroxide, 3g / l penetrating agent JFC, 3g / l scouring aid Sodium bisulfite), with a liquid volume of 120%, and then two-stage steam flash explosion treatment (the hemp fabric is heated and pressurized to 4.5MPa in the steam flash explosion processor, and the pressure is kept for 8s, and then the controlled flash explosion is depressurized to 2.8 MPa, further pressurized for 8s, and then fully flashed to normal pressure), and then taken out for washing and drying.

[0041] Bleaching treatment: the hemp fabric after the steam flash scouring and bleaching pretreatment is completed under the condition of pH=4 to soak the bleaching liquor (sodium chlorite of 20g / l, 11g / l ammoniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com