Hook-headed type wedge key anti-loosening device of railway wagon and railway wagon

A railway freight car and wedge key technology, applied in railway car body parts, hopper cars, transport passenger cars, etc., can solve problems such as affecting the interchangeability of accessories and repairing efficiency, affecting the safety of train transportation, and improper welding precautions, etc. Improve anti-loosening and anti-dropping technology and functions, improve assembly efficiency and quality, and improve the effect of versatility and interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

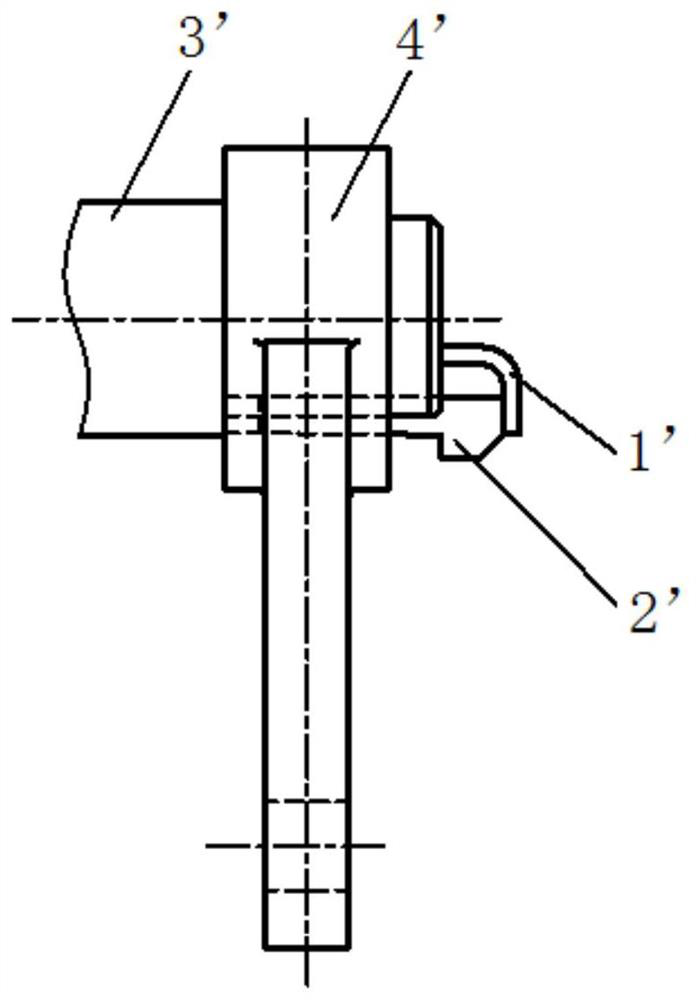

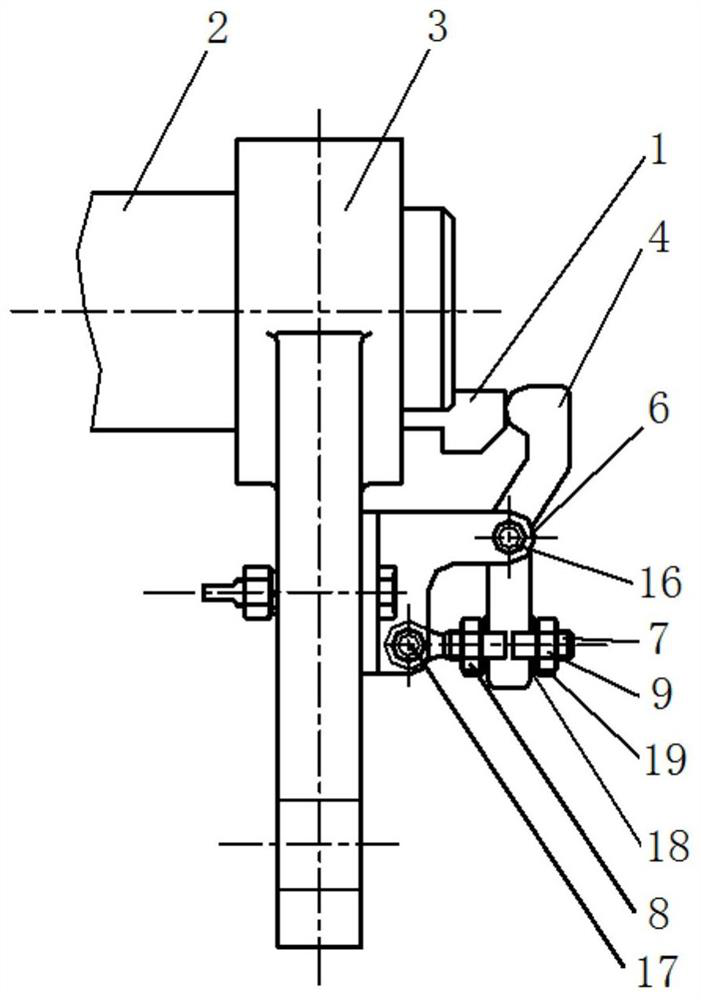

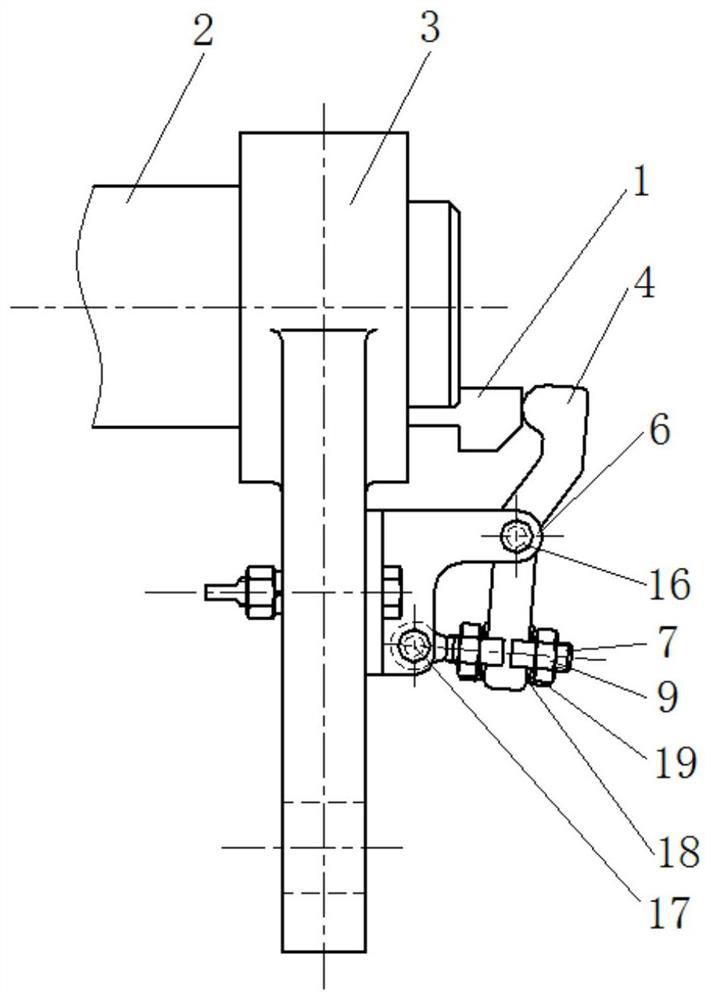

[0100] Such as Figure 2 to Figure 15 As shown, the present invention provides a hook head type wedge key anti-loosening device for railway wagons, which is used for anti-loosening of the key connection structure between the transmission shaft and the crank throw, including:

[0101] The hook head type wedge key 1 is matched with the keyway on the transmission shaft 2 and the crank throw 3;

[0102] A lever 4, one end of the lever 4 abuts against the exposed end of the hook-shaped wedge key 1, and the other end of the lever 4 is provided with an oblong hole 5;

[0103] Mounting seat 6, one side of mounting seat 6 is arranged on the web plate of crank throw 3, and the other side of mounting seat 6 is hinged with the middle part of lever 4 near one end of hook head type wedge key 1;

[0104] Swing bolt 7, the round hole of swing bolt 7 is hinged with the other side of mounting seat 6 away from the end of hook head type wedge key 1, the middle part of the screw rod of swing bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com