Double-pipe metering device, double-pipe metering method and double-pipe metering system

A technology of measuring device and measuring method, which is applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring differential pressure. , reduce labor intensity and production cost, optimize the effect of measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

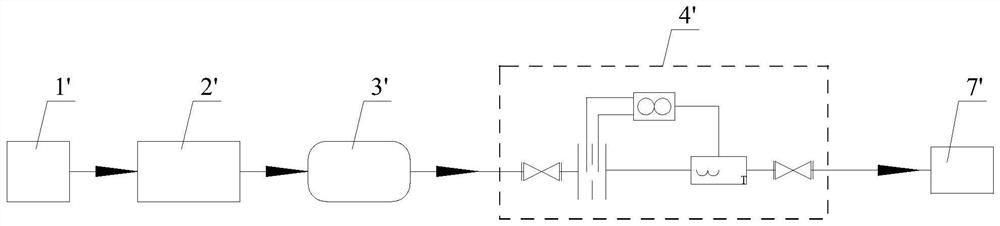

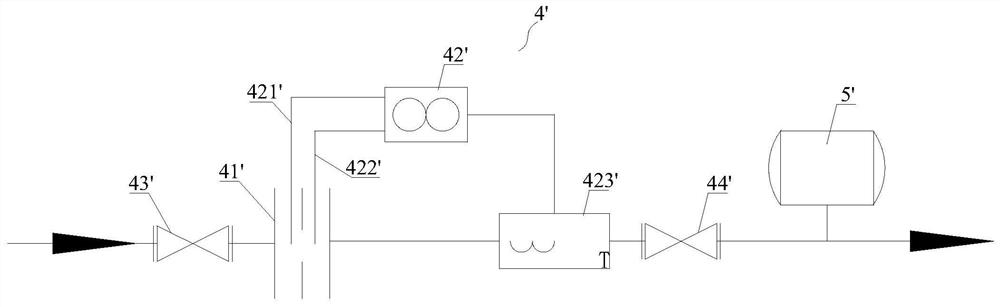

[0051] Such as Figure 4 As shown, the natural gas from the wellhead 1 passes through the water jacket furnace 2, the separator 3 and the metering section in sequence, and then is transported to the user end through the gathering and transportation pipeline 7, wherein the metering section includes the main channel metering section 4 and the bypass channel which are connected in parallel and have the same structure. The metering section 5 and the bypass metering section 5 cooperate with the main metering section 4 to measure the flow of natural gas delivered to the gathering and transportation pipeline 7 .

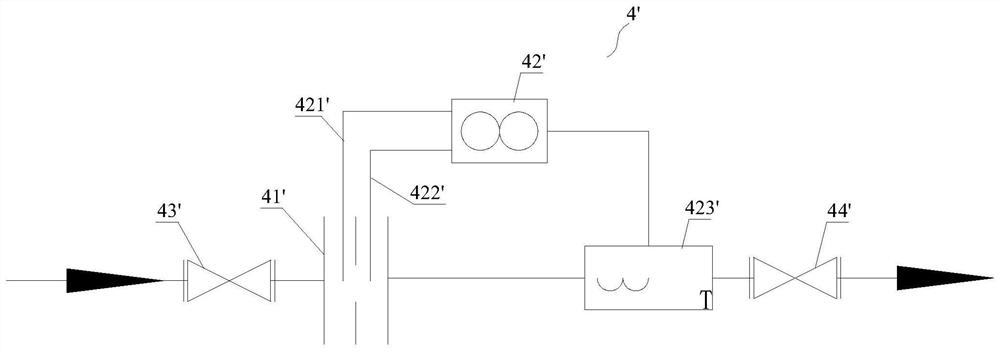

[0052] Such as Figure 5-6 As shown, the main metering section 4 includes an inlet valve-43, an orifice throttling device-41, a differential pressure flowmeter-42 and an outlet valve-44 connected in series in sequence; the differential pressure flowmeter-42 passes through the low-pressure pipeline- 421 and high-pressure pipeline one 422 collect and form pressure difference...

Embodiment 2

[0060] Such as Figure 7 shown, combined with Figure 3-5 , the operation steps of the double-tube metering method using the double-tube metering device are:

[0061] A. When the flow Q in the main flow metering section 4 is stable and less than the set value Q1, keep the inlet valve 2 53 and the outlet valve 2 54 in a closed state, so that the main flow metering section 4 can be measured separately;

[0062] B. When the flow Q in the main metering section 4 continues to rise and reaches the set value Q1, open the outlet valve 2 54 and the inlet valve 2 53 in sequence to make the bypass metering section 5 start metering, that is, double-pipe metering.

[0063] C. When the flow Q in the main flow metering section 4 continues to drop and is lower than the set value Q1, close the inlet valve 2 53 and the outlet valve 2 54 in turn, so that the bypass metering section 5 stops measuring and returns to the main flow metering section 4 Individually metered status.

[0064] Wherein,...

Embodiment 3

[0070] Such as Figure 8 As shown, the double-pipe metering system includes a double-pipe metering device and a corresponding control system 6 .

[0071] Among them, the inlet valve 2 53 and the outlet valve 2 54 are both hydraulic gate valves, and their hydraulic control system is connected to the control system 6; the flow Q data output by the differential pressure flowmeter 1 42 is also sent to the control system 6; the control system 6. Monitor the flow Q in real time, and control the opening and closing of the inlet valve 2 53 and the outlet valve 2 54 according to the operation steps described in Embodiment 2, thereby replacing manual double-pipe metering control; the specific steps are as follows:

[0072] Set the threshold Q2 of the flow Q in the control system 6, and the setting value of Q2 should be consistent with or close to Q1, which can be set as 70% of the range of the differential pressure flowmeter one (42), or according to the control system 6 According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com