Circuit measuring system for substrate

A circuit and substrate technology, applied in the field of substrate circuit measurement system, can solve problems such as slow measurement time, unsatisfactory electrical performance, inaccurate line width measurement, etc., to improve accuracy and increase detection accuracy , the effect of increasing the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

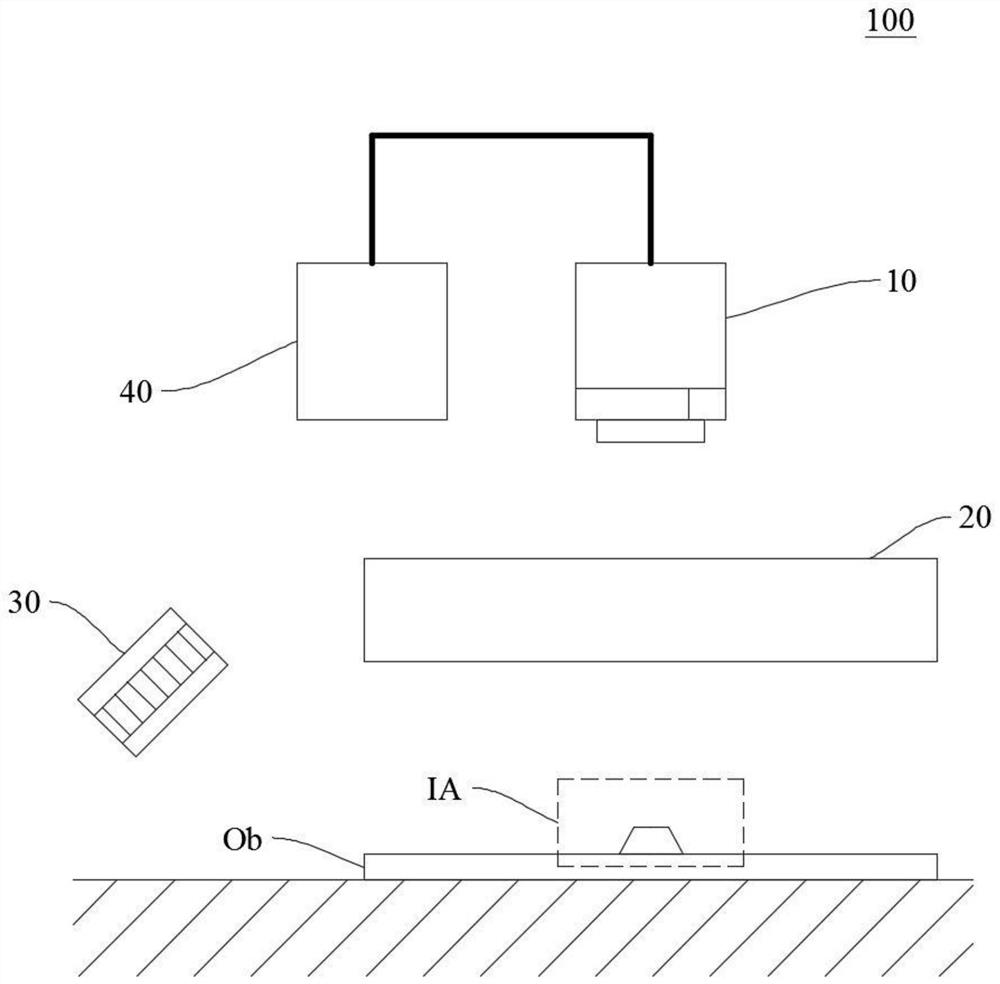

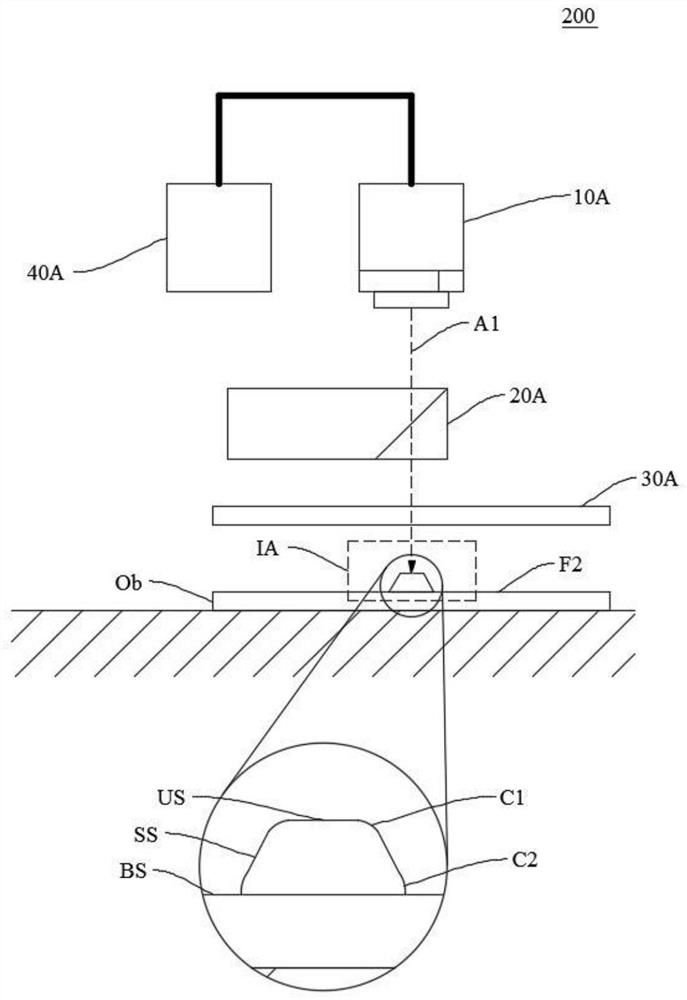

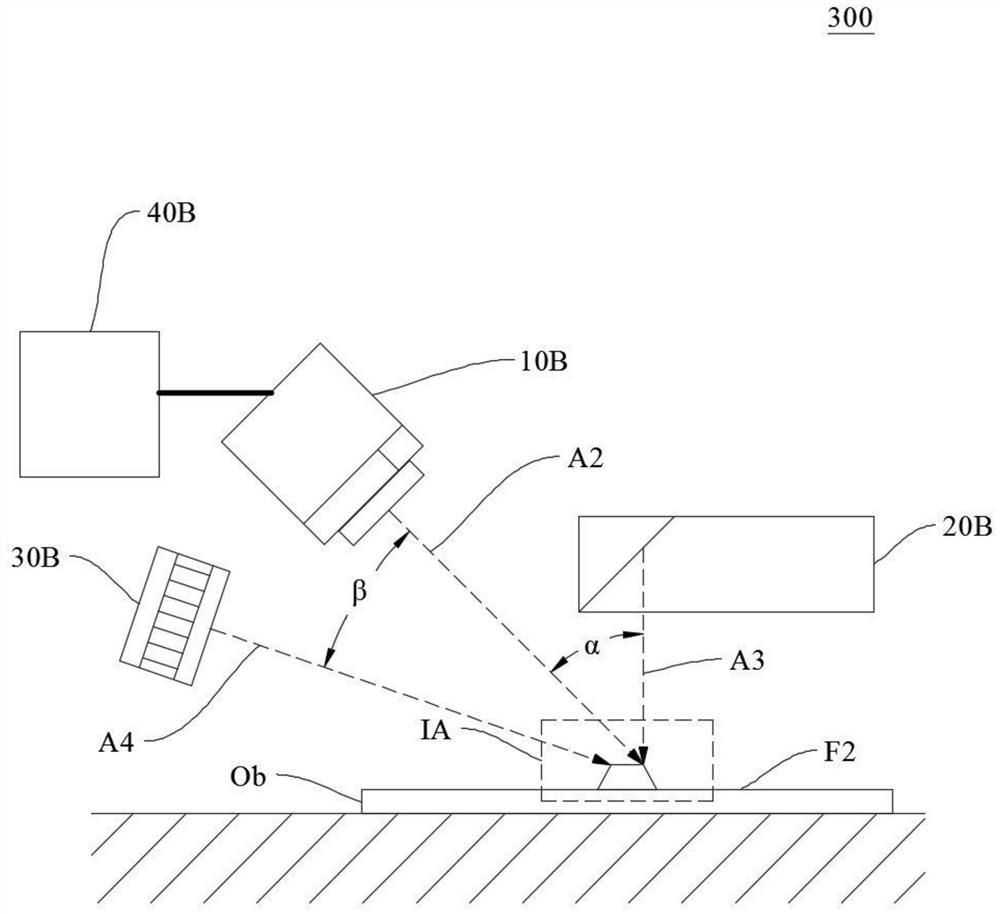

[0113] Please refer to " figure 1 " is a schematic block diagram of the line measurement system of the present invention. The line measurement system 100 of this embodiment mainly includes an image capture device 10 , a first light source 20 , a second light source 30 and an image processing device 40 .

[0114] The image capture device 10 is used to capture the image of the substrate Ob to obtain an image of the substrate. The image capture device 10 includes but is not limited to, for example, a color camera for photographing the substrate Ob on the inspection area IA. Wherein the substrate Ob includes at least one substrate circuit. In one embodiment, the image capture device 10 may be an area scan camera or a line scan camera.

[0115] The first light source 20 provides light beams of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com