Method for analyzing degree of sugar-based oxidation of fish eggs through in-vitro model

A technology of oxidation degree and fish meat protein, which is applied in the direction of material inspection, food testing, etc., can solve problems such as multi-factor interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

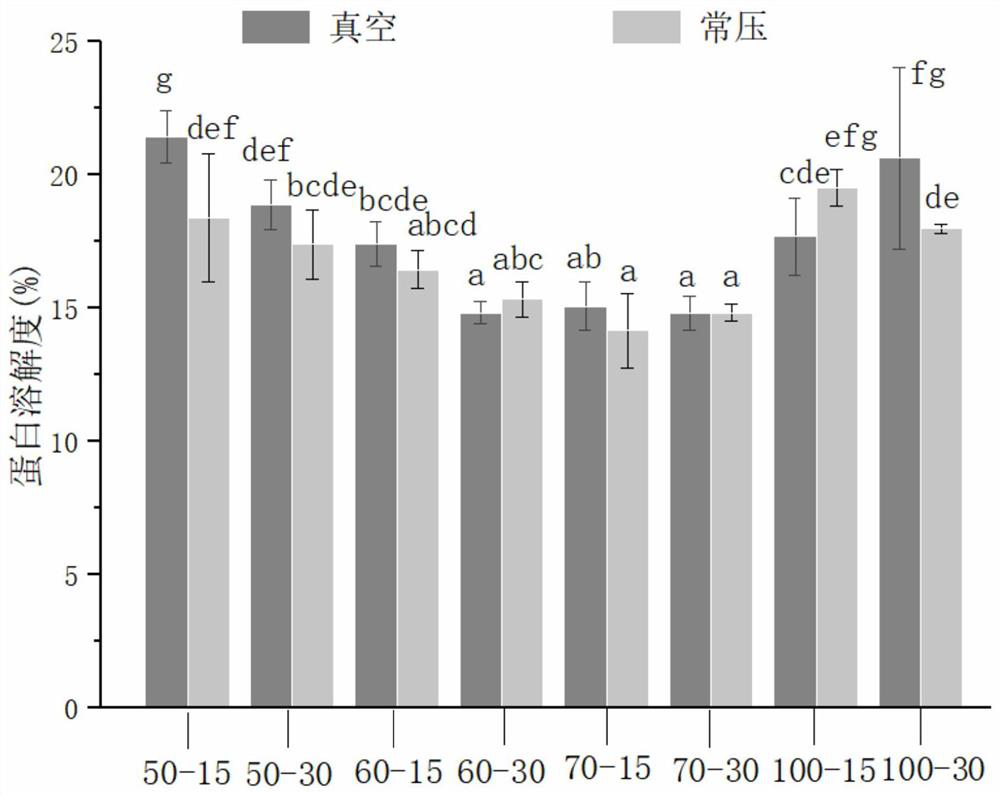

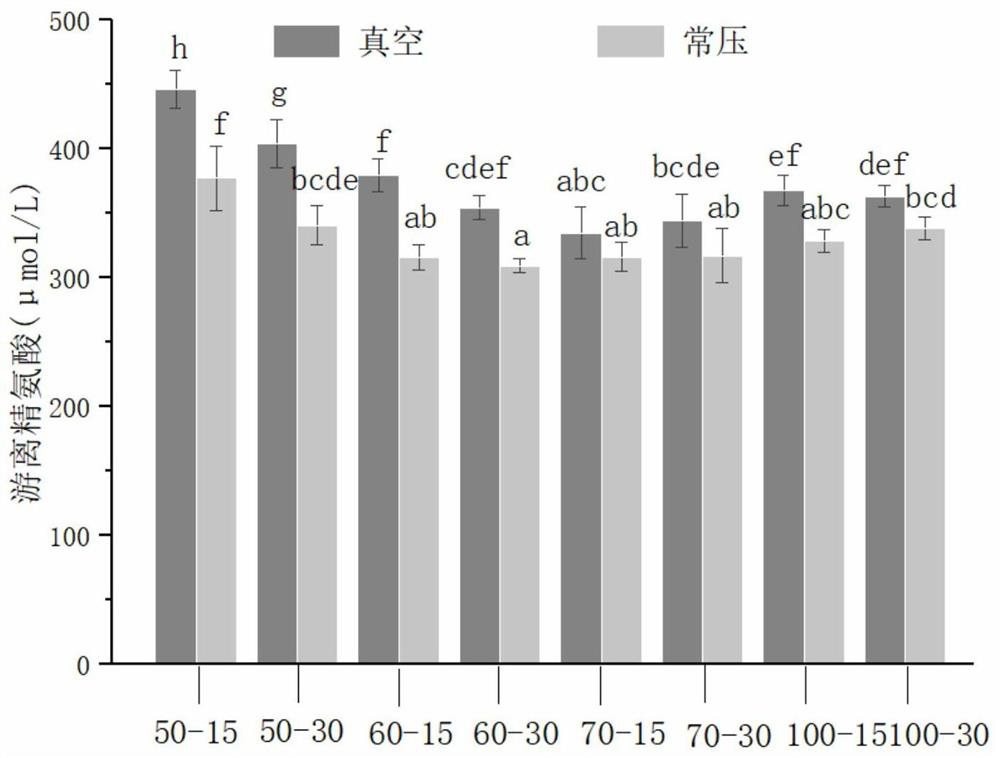

[0054] To compare the degree of protein oxidation of sturgeon meat during vacuum low heat processing and atmospheric pressure low heat processing.

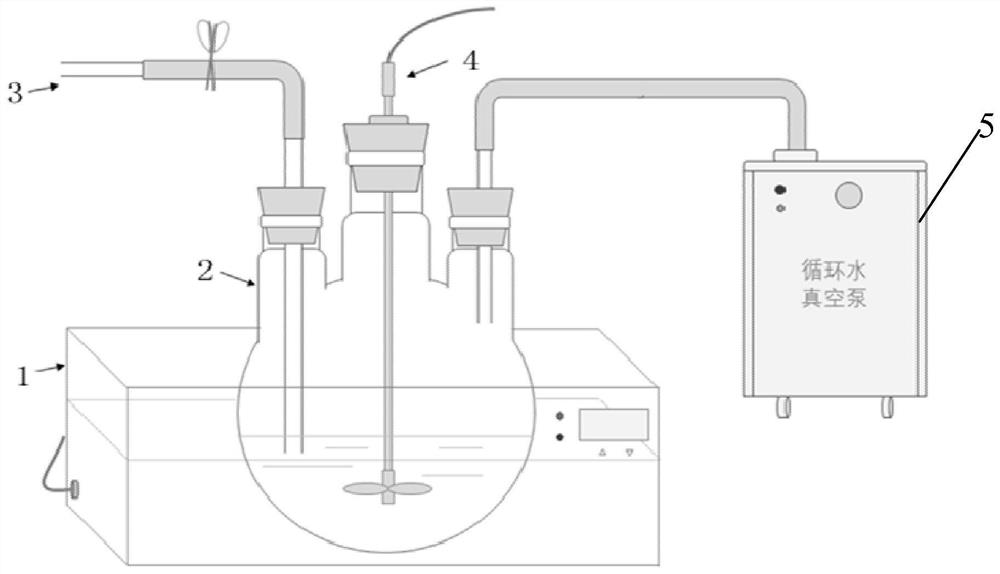

[0055] (1) Construction of in vitro model device

[0056] Use a constant temperature water bath, circulation pump, electric stirrer, three-necked flask, catheter, etc. to set up such as figure 1 device shown. The feeding pipe goes deep below the liquid level in the bottle, and the circulating pump conduit is higher than the liquid level in the bottle.

[0057] (2) Preparation of myofibrillar protein precipitate

[0058] 10 g of fish samples were defatted, chopped, put into a beater, added 100 mL of 50 mmol / L phosphate buffer (pH=7.0) containing 0.1 mol / L NaCl, beat and crushed for 1 min in an ice bath, and centrifuged at 8000 g for 10 min (4 ℃), remove the supernatant, wash twice to remove water-soluble protein; add 200mL 50mmol / L phosphate buffer (pH=7.0) containing 0.6mol / L NaCl and mix with the precipitate, extract at 4℃ for 1...

Embodiment 2

[0065] Analysis of protein glycosylation and anti-oxidation in sturgeon meat during vacuum low heat process.

[0066] (1) Construction of in vitro model device

[0067] Use a constant temperature water bath, circulation pump, electric stirrer, three-necked flask, catheter, etc. to set up such as figure 1 device shown. The feeding pipe goes deep below the liquid level in the bottle, and the circulating pump conduit is higher than the liquid level in the bottle.

[0068] (2) Preparation of myofibrillar protein freeze-dried powder

[0069] Remove the fat from 10g fish sample, chop it, put it into a beater, add 100mL of 50 mmol / L phosphate buffer (pH=7.0), beat and crush it in an ice bath for 1min, centrifuge at 8000g for 10min (4°C), and remove the supernatant , repeated washing 4 times to remove water-soluble protein; add 200mL 50mmol / L phosphate buffer (pH=7.0) containing 0.6mol / L NaCl and mix well with the precipitate, extract at 4°C for 12h, centrifuge at 8000g for 10min (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com