Printing VOC waste gas treatment system

A waste gas treatment and waste gas technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of limited VOC waste gas contact and low efficiency of VOC waste gas treatment, and achieve the effect of optimizing catalytic degradation and reducing waste gas content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

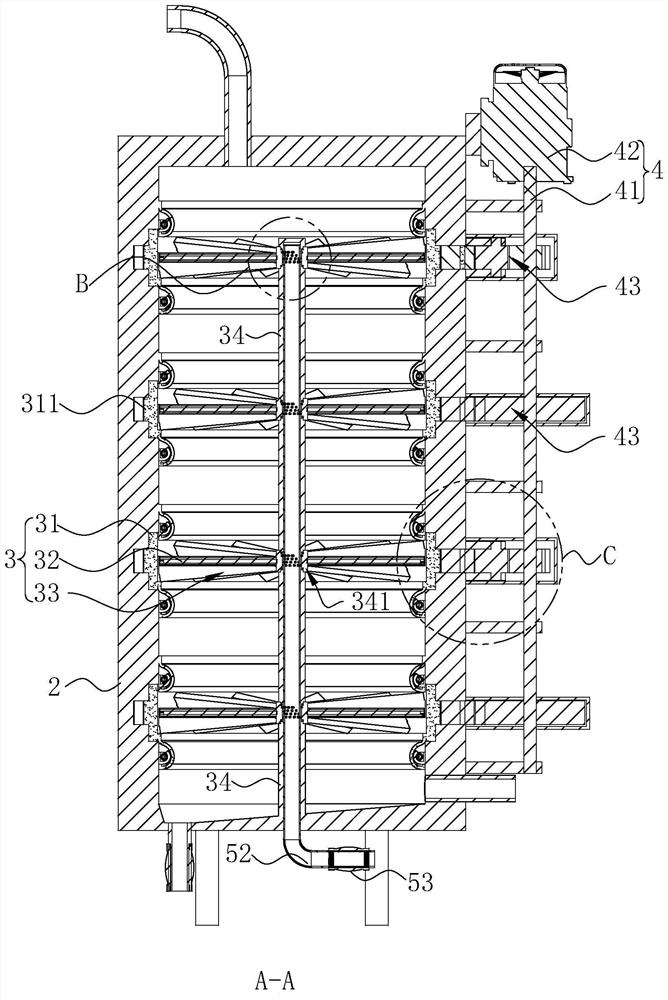

[0035] The following is attached Figure 1-5 The application is described in further detail.

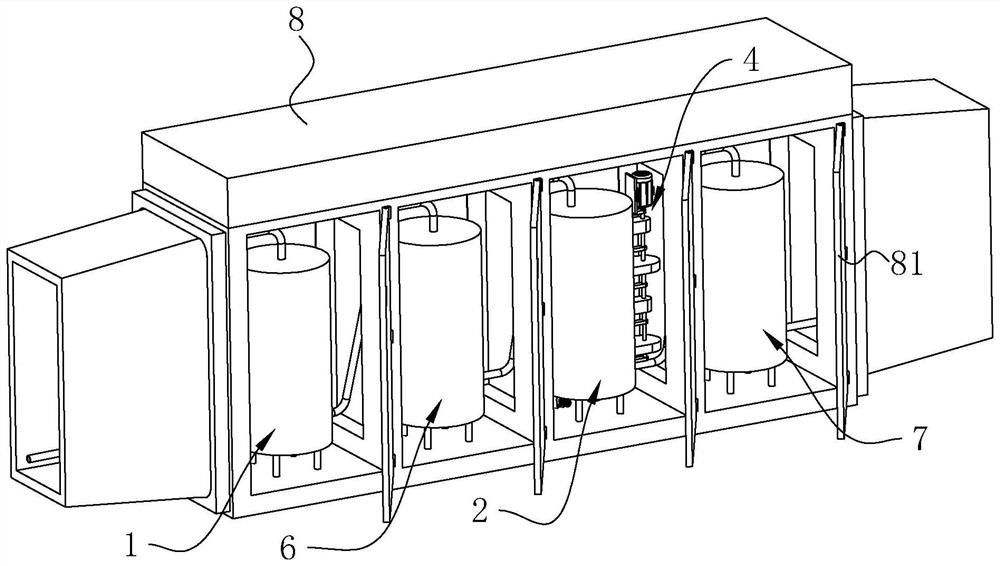

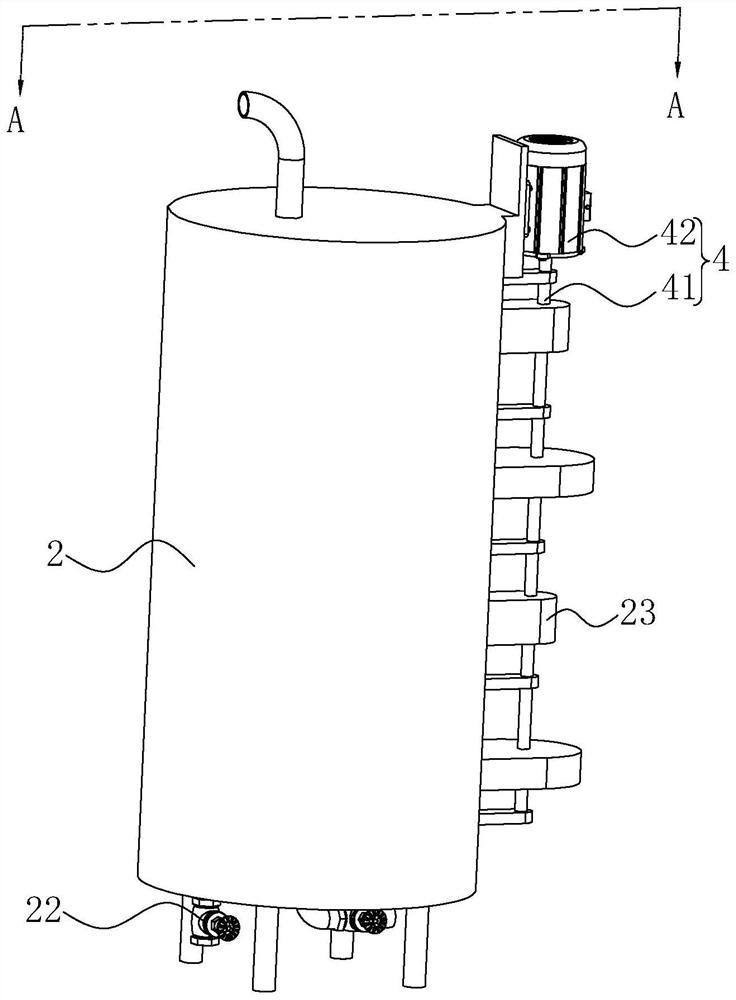

[0036] The embodiment of the present application discloses a printing VOC waste gas treatment system. refer to figure 1 and figure 2 , the printing VOC waste gas treatment system includes an initial effect purification mechanism 1 , a photo-oxygen purification mechanism 6 , a photocatalytic mechanism and an ozone purification mechanism 7 . The air inlet end of the primary effect purification mechanism 1 is used to communicate with the printing waste gas discharge pipeline, the air outlet end of the primary effect purification mechanism 1 is connected to the air inlet end of the photooxygen purification mechanism 6 through a pipeline, and the gas outlet end of the photooxygen purification mechanism 6 is connected through a pipeline At the air inlet end of the photocatalytic mechanism, the air outlet end of the photocatalytic mechanism is connected to the air inlet end of the ozone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com