Ejecting mounting mechanism for assembling missiles under belly of airplane and control method of ejecting mounting mechanism

A missile and top-mounted technology, applied in two-dimensional position/course control, aircraft parts, non-electric variable control, etc., can solve the problems of complex operation of equipment, interference of power supply lines, low work efficiency, etc., and achieve high transmission efficiency, Responsive, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

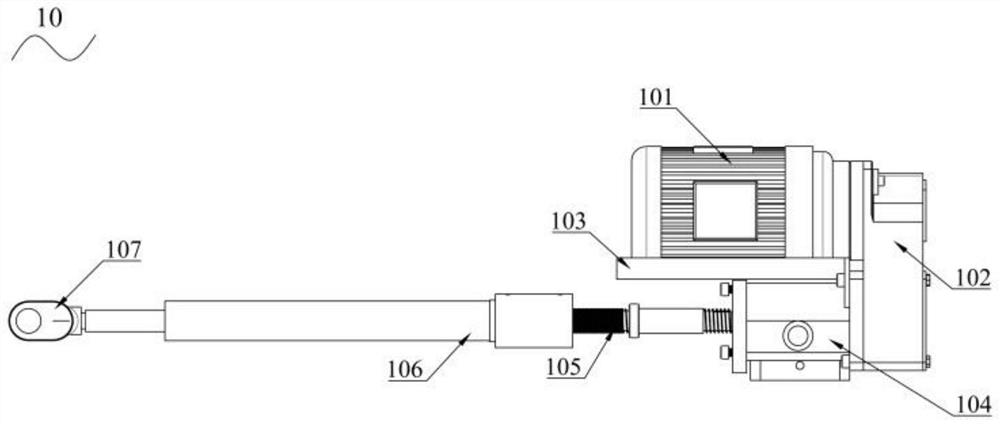

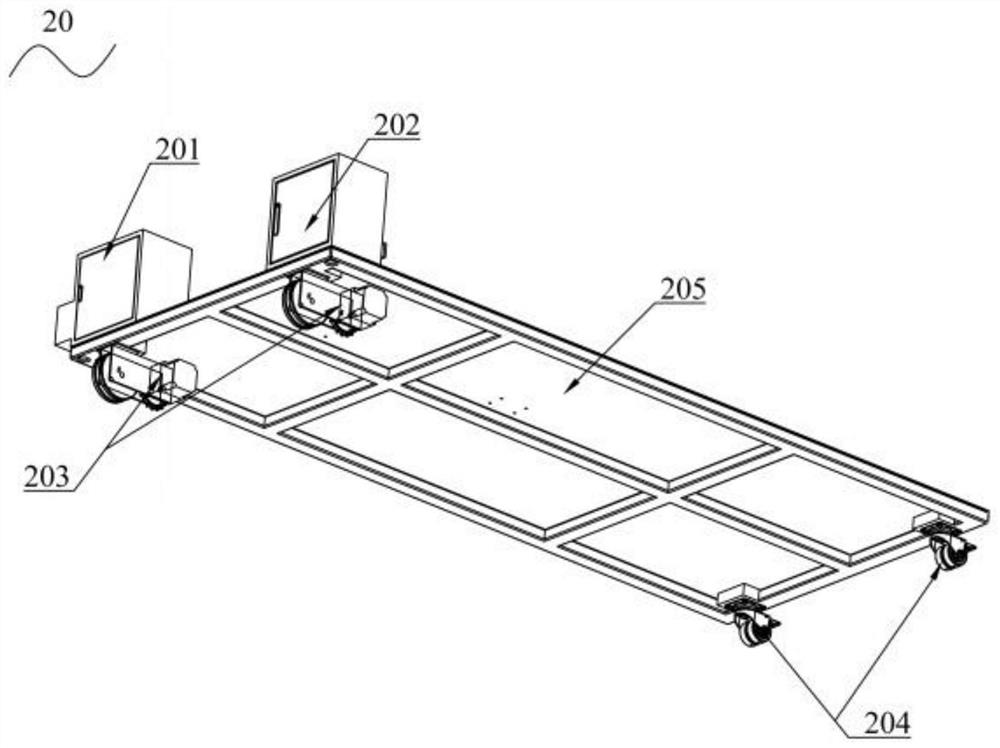

[0036] Specific implementation mode one: see Figure 1-8This embodiment will be described. The top loading mechanism for missile assembly under the belly of the aircraft described in this embodiment includes a power transmission mechanism 10 based on a planetary roller screw, a travel control mechanism 20, an upper platform support mechanism 30, a scissor lift mechanism 40 and a base 205, the upper end of the scissor lift mechanism 40 is connected to the upper platform support mechanism 30, and the bottom is installed on the slideway of the base 205, the travel control mechanism 20 remotely controls the base 205 to advance to the designated station, and the power transmission mechanism 10 controls the scissors Type elevating mechanism 40 rises or descends to missile installation height.

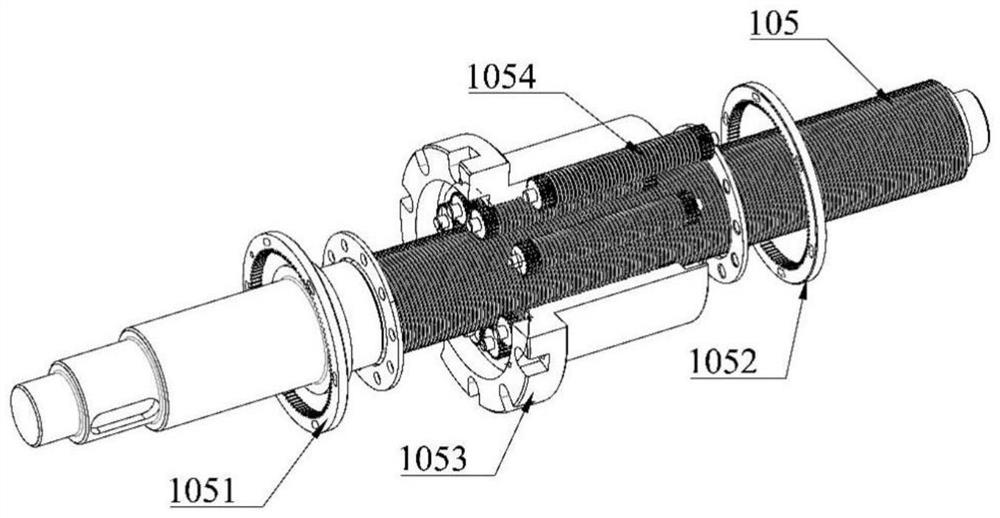

[0037] The power transmission mechanism based on the planetary roller screw includes a screw drive motor 101, a screw drive motor reducer 102, a planetary roller screw lever 105 and a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com