High-solid-content thermoplastic waterborne polyurethane emulsion and preparation method thereof

A technology of water-based polyurethane with high solid content, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problems of low solid content of emulsion, resistance to hydrolysis, complicated preparation, etc., and achieve low temperature hot melting Good resistance, poor hydrolysis resistance, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

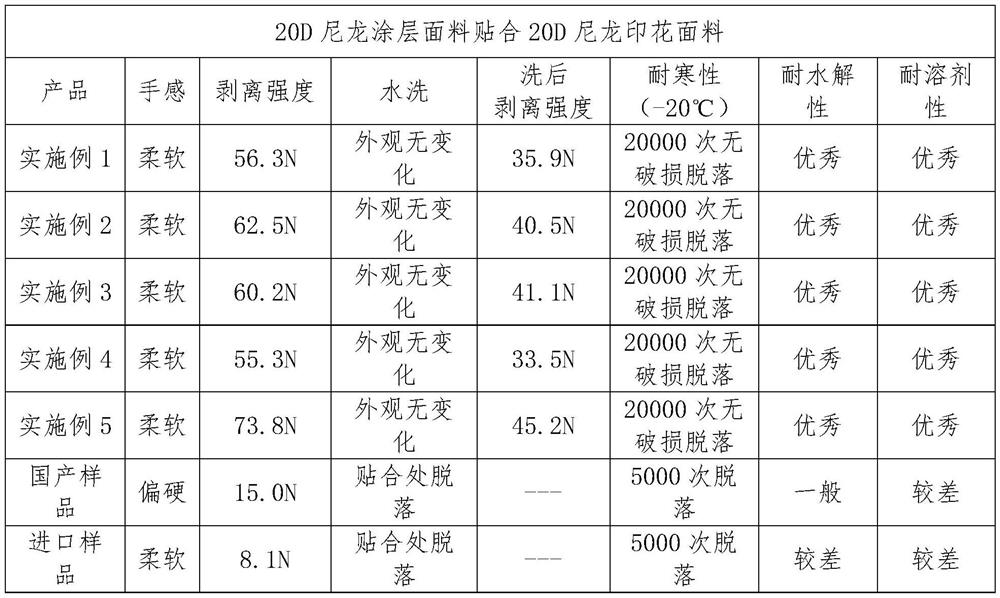

Examples

Embodiment 1

[0037] Preparation Example 1 A high solids aqueous polyurethane emulsion of the thermoplastic embodiment

[0038] HDI trimer selected NCO content (21.8 ± 0.3)% Wanhua Chemical Company;

[0039] Polytetramethylene ether glycol selected number-average molecular weight of polytetramethylene ether glycol of 2000;

[0040] Polycarbonate diols selected number average molecular weight of polycarbonate diol of 1000;

[0041] Chain extenders chain extender is hydroxy sulfonates, number average molecular weight of 270, the product selected from a double bond Chemical Co. Taiwan;

[0042] Small molecule chain extender selected hydrazine hydrate;

[0043] Catalyst selection of America's leading chemical company organic bismuth catalysts BiCAT 8118

[0044] raw material:

[0045] Isophorone diisocyanate (IPDI) 55 parts

[0046] 20 parts of HDI trimer

[0047] Polytetramethylene ether glycol 30 parts

[0048] 100 parts of polycarbonate diol

[0049] 2 parts of neopentyl glycol

[0050] 0.2 parts...

Embodiment 2

[0066] Example 2 Preparation of a high solids content of the aqueous polyurethane emulsion of the thermoplastic embodiment

[0067] HDI trimer selected NCO content (21.8 ± 0.3)% Wanhua Chemical Company;

[0068] Polytetramethylene ether glycol selected number-average molecular weight of polytetramethylene ether glycol of 2000;

[0069] Polycarbonate diols selected number-average molecular weight of polycarbonate diol of 2000;

[0070] The chain extender is a hydroxy sulfonate chain extender having a number average molecular weight of 450, the product selected from a double bond Chemical Co. Taiwan;

[0071] Select a small molecule chain extender isophorone diamine;

[0072] Catalyst selection of America's leading chemical company organic bismuth catalysts BiCAT 8124.

[0073] raw material:

[0074] Isophorone diisocyanate (IPDI) 55 parts

[0075] 25 parts of HDI trimer

[0076] Polytetramethylene ether glycol 30 parts

[0077] 110 parts of polycarbonate diol

[0078] 2 parts of ne...

Embodiment 3

[0095] Example 3 Preparation of a high solids content of the aqueous polyurethane emulsion of the thermoplastic embodiment

[0096] HDI trimer selected NCO content (21.8 ± 0.3)% Wanhua Chemical Company;

[0097] Polytetramethylene ether glycol selected number-average molecular weight of polytetramethylene ether glycol of 1500;

[0098] Polycarbonate diols selected number average molecular weight of polycarbonate diol of 1000;

[0099] Chain extenders chain extender is hydroxy sulfonates, number average molecular weight of 270, the product selected from a double bond Chemical Co. Taiwan;

[0100] Select a small molecule chain extender 2.3 parts of hydrazine hydrate and 4.5 parts of isophoronediamine mixed solution;

[0101] Catalyst selection of America's leading chemical company organic bismuth catalysts BiCAT 8108.

[0102] raw material:

[0103] Isophorone diisocyanate (IPDI) 60 parts

[0104] 20 parts of HDI trimer

[0105] Polytetramethylene ether glycol 40 parts

[0106] 90 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com