Semi-reverse construction method for large-span corridor structure along street

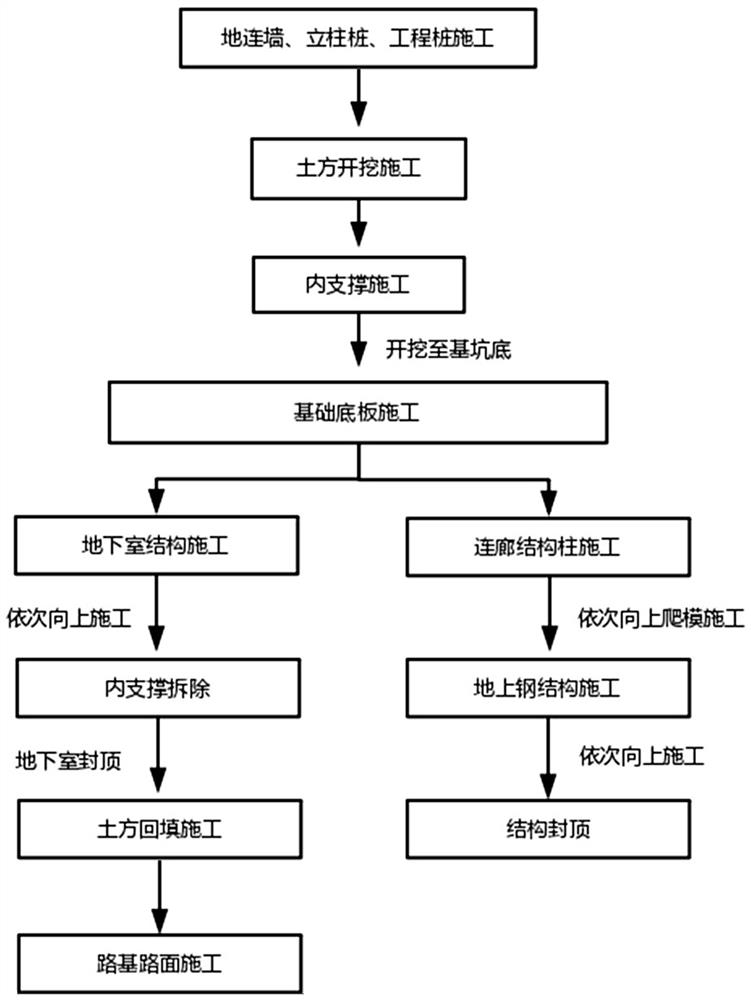

A construction method and large-span technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., to achieve the effect of shortening the construction period, reducing the risk of delay, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

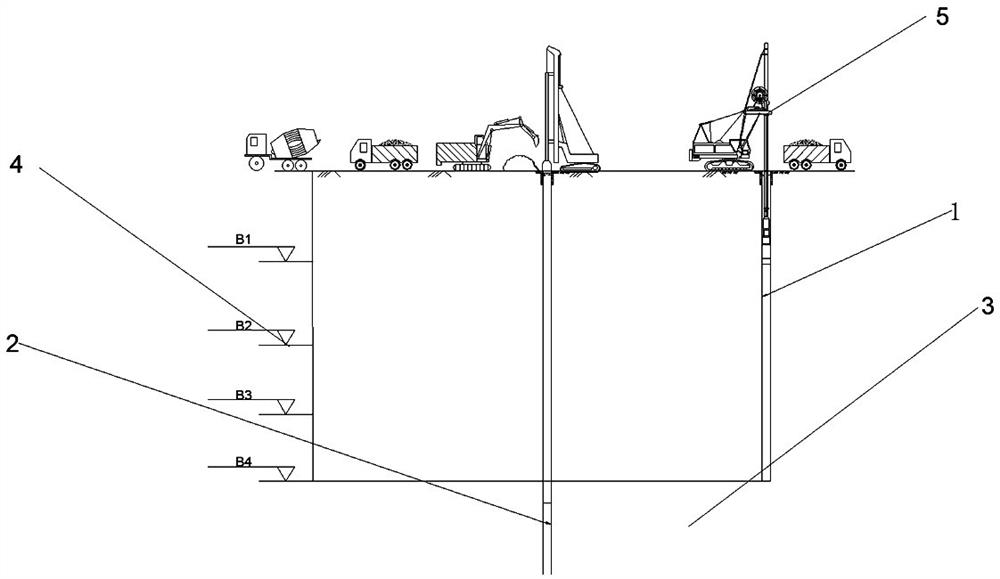

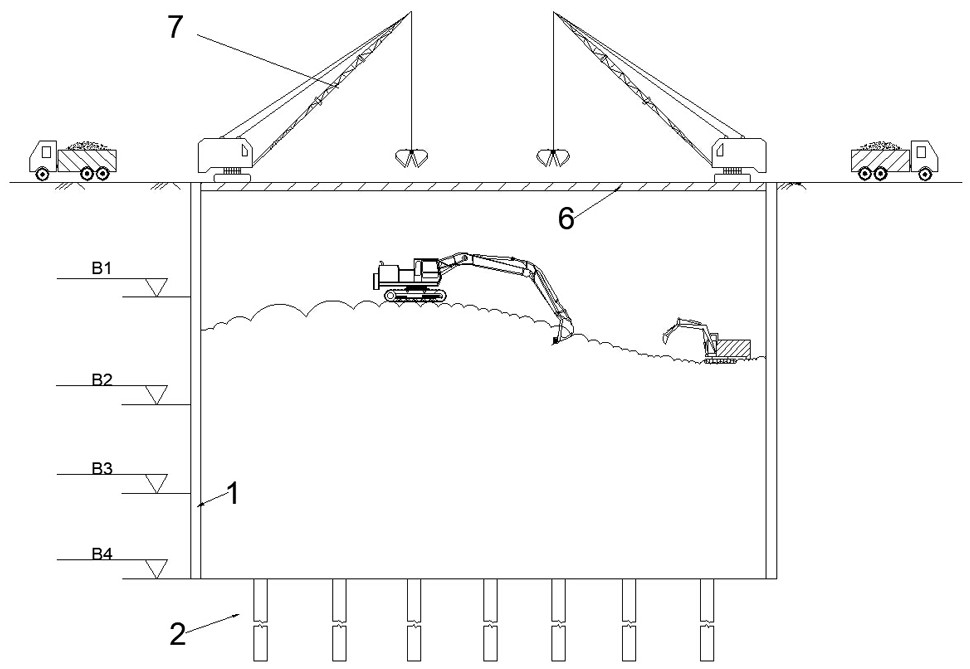

[0042] Take a financial center project, which is located at the intersection of roads, and its structure is a frame core tube structure. The project is positioned as an urban complex integrating offices, commerce, and high-end hotels. The project is located in the bustling central area, and it is the main traffic artery in the urban area, with a large traffic flow and dense underground pipelines. The bridge connecting the south tower project and the north tower project connects the south tower and the north tower through the underground B2-B5 floors and the ground L3-L7 floors. The basement is a reinforced concrete frame structure, and the ground corridor is a steel structure. Supported by eight giant columns. Temporary connecting wall 1 is divided into two independent foundation pits, the deepest foundation pit of the south tower is 37.4m, and the area of the south tower foundation pit is 6940㎡; the other foundation pit has an area of 4240㎡, and the safety level of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com