Drying production line and control method thereof

A technology of production line and drying equipment, applied in drying, drying machine, drying solid materials, etc., can solve problems such as low efficiency and complicated control of drying production line, so as to improve production efficiency and reduce the difference in completion time. , the effect of reducing control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The dried production line provided in the embodiment of the present invention is applied to tobacco drying, tea drying, wood drying, sea product drying and other drying scenarios, and improves its production efficiency, and is not easy. The material is boring.

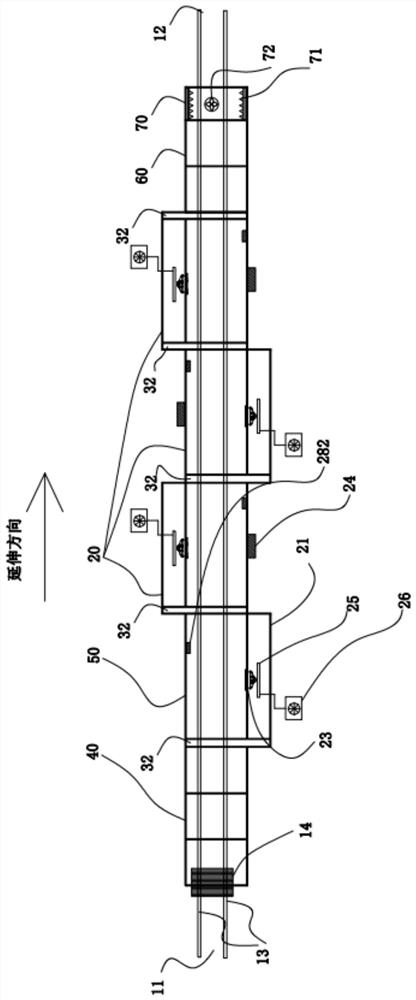

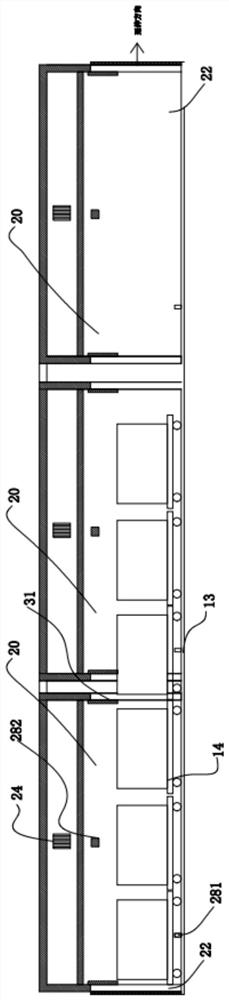

[0063] like Figure 1 to 2 As shown, the drying production line of the present embodiment includes a feed position 11, the assembly position 12, and the plurality of drying apparatus 20, and the feed position 11 and the assembly position 12 are provided with a rail unit 13, wherein different The drying apparatus 20 is used to perform different wetting dehumidification steps; the plurality of drying apparatus 20 are sequentially disposed on the track unit 13 along the extension direction of the rail unit 13. In the present embodiment, the number of drying apparatus 20 is three, and each configures different parameters, for example, figure 1 The target humidity of the material obtained from the three drying apparatus 2...

Embodiment 2

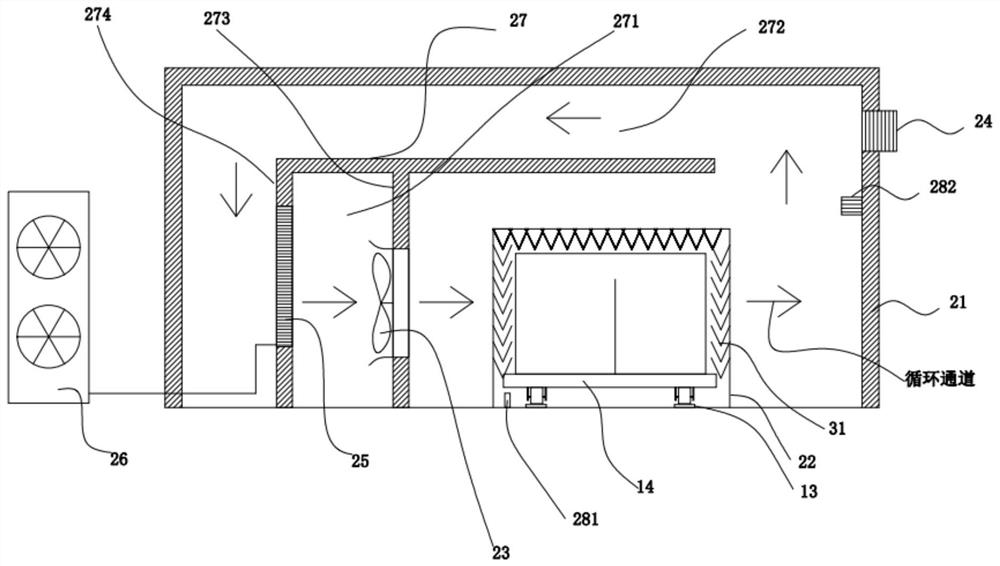

[0091] This example describes the control method of the above drying production line. It is necessary to supplement that the drying housing 21 is also provided with a monitoring sensor 281 for detecting whether the carrier unit 14 is present, and the temperature and humidity sensor 282 and the main control unit 283 for detecting temperature and humidity. Among them, the monitoring sensor 281 is used to detect whether the material to be dry within the drying apparatus 20 may be a metal bracket of a carrier, or a material on a carrier vehicle. The temperature and humidity sensor 282 can be used to monitor the dry ball wet ball temperature in the drying apparatus 20, and the main control unit 283 can calculate the humidity in real time according to the dry ball wet ball temperature.

[0092] The master unit 283 is electrically connected to the dehumidification unit 24, the temperature and humidity sensor 282, and the monitoring sensor 281, respectively. More specifically, the master ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com