Simulation system for predicting auto-thermal reforming reaction of diesel oil, prediction method and medium

A technology of autothermal reforming and simulating system, applied in the fields of instrumentation, computational theoretical chemistry, chemical process analysis/design, etc., to achieve the effect of good prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Diesel composition analysis and simulation and determination of simulated components of diesel to be predicted

[0124] (1) Based on the "National VI" standard No. 0 diesel oil, experiments and modeling were carried out, and its components were analyzed experimentally. The analysis results show that the molecular formula of No. 0 diesel oil used in the experiment is C 14.3 h 27.4 , the mass content of carbon element is 86.32%, the mass proportion of hydrogen element is 13.68%, and the sulfur element is 5mg / L. The mass proportion of the experimental diesel oil hydrocarbon components is shown in Table 1.

[0125] Table 1 Hydrocarbon components of experimental diesel oil

[0126]

[0127]

[0128] (2) Using normal alkanes, single-ring aromatics and bicyclic aromatics to simulate diesel oil, the carbon number distribution of n-alkanes is C9-C20, accounting for 79.9% by mass; the carbon number distribution of single-ring aromatics is C11-C18, accounting for 7.4% by m...

Embodiment 2

[0133] A method for predicting diesel autothermal reforming reactions includes the following steps:

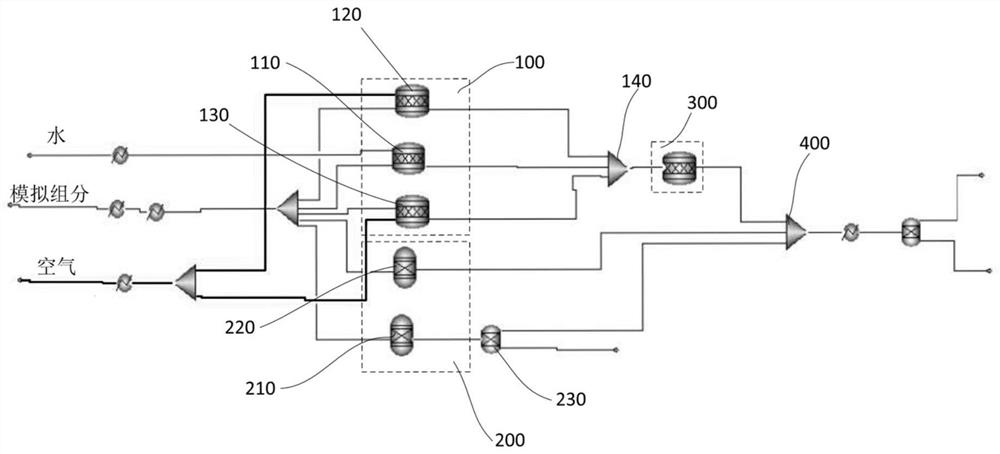

[0134] The first simulator 110 is configured according to the steam reforming reaction in the autothermal reforming main reaction. The second simulator 120 is configured according to the partial oxidation reforming reaction in the autothermal reforming main reaction. The third simulator 130 is configured according to the complete oxidation reaction. The first simulator 110, the second simulator 120 and the third simulator 130 are the stoichiometric ratio reactor "RStoic" modules in ASPEN respectively. At the same time, the reaction temperature and reaction pressure of each simulator were set to 750° C. and 1 bar.

[0135] The fourth simulator 210 is configured according to the reaction of pyrolysis to generate carbon deposits, small molecule olefins and alkanes. The fifth simulator 220 is configured according to the reaction of unconverted or incompletely converted diesel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com