Method for predicting microstructure change of near-alpha type titanium alloy aviation die forging

A technology of microstructure and prediction method, applied in chemical property prediction, furnace type, chemical statistics, etc., to improve production efficiency, increase yield, and reduce waste

Active Publication Date: 2021-09-17

YANSHAN UNIV +1

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to overcome the defects of the prior art, the object of the present invention is to provide a method for predicting the microstructure change of near-α-type titanium alloy aviation die forgings, which can effectively predict the content and Reducing the content of primary α-phase during hot die forging solves a series of problems caused by dynamic phase transformation, and then can provide optimization ideas for the deformation process of titanium alloy die forgings, increase the yield of forgings, reduce production costs, and improve production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0066] Specifically, the present invention provides a prediction method for evaluating microstructure changes of near-α-type titanium alloy die forgings, the steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

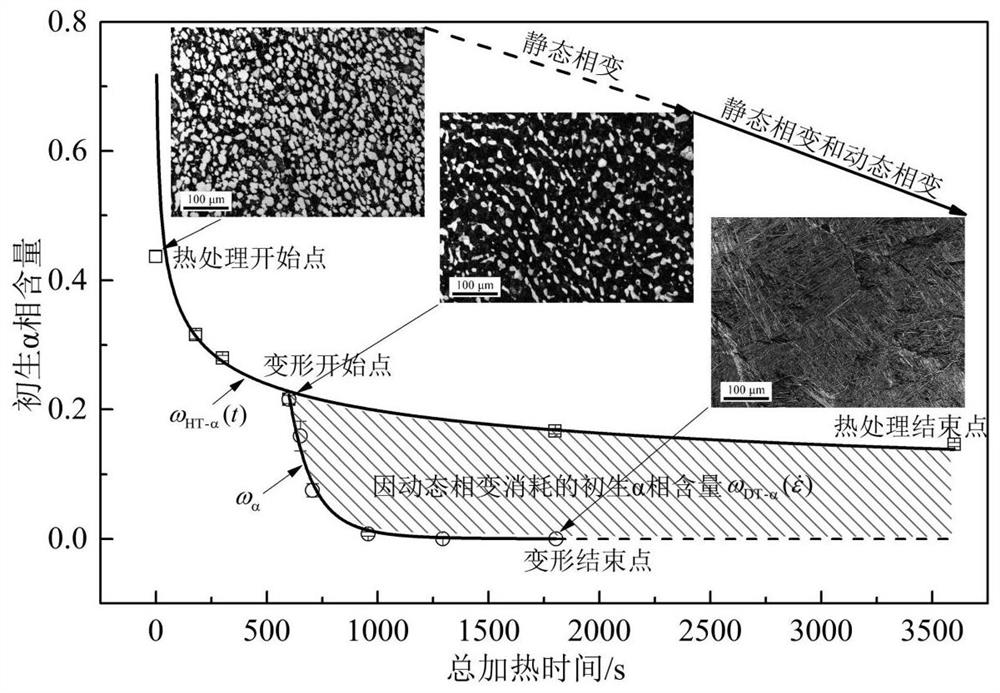

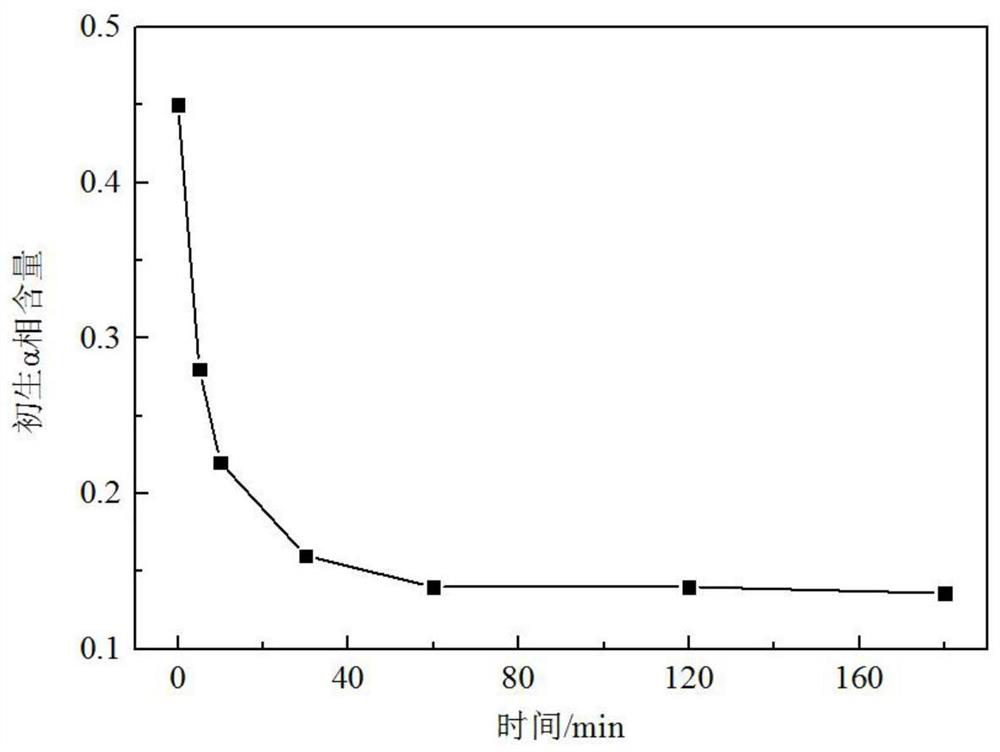

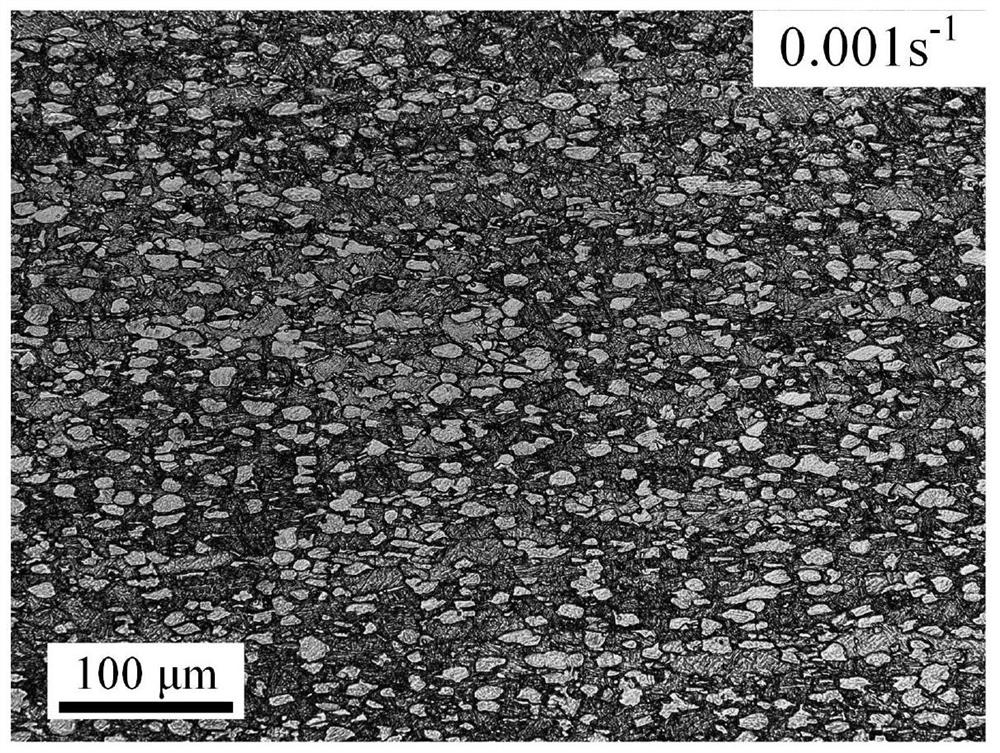

The invention provides a method for predicting microstructure change of a near-alpha type titanium alloy aviation die forging. The method comprises the following steps: S1, measuring microstructures of a material under different process conditions; S2, carrying out statistical analysis on the microstructure of the core part of the test piece under different treatment processes, especially the content change of a primary alpha phase; S3, establishing a prediction model of primary alpha phase change; S4, performing a die forging test; and S5, based on the prediction model of the primary alpha-phase change, realizing visual prediction of the microstructure change of the near-alpha titanium alloy die forging through finite element numerical simulation analysis. According to the method for predicting the microstructure change of the near-alpha type titanium alloy aviation die forging, the distribution rule of the primary alpha phase of the near-alpha titanium alloy blank after high-temperature die forging and the content of the primary alpha phase consumed due to dynamic phase change can be effectively predicted, and visual prediction of the change of the primary alpha phase in the microstructure is achieved.

Description

technical field [0001] The invention belongs to the technical field of forging forming microstructure prediction models of titanium alloy forgings, and relates to a method for predicting microstructure changes of nearly α-type titanium alloy aviation die forgings. Background technique [0002] Titanium alloy is an extremely important lightweight structural material with outstanding characteristics such as high specific strength, good corrosion resistance, and good high and low temperature performance. It has very important application value and broad application in the fields of aviation, aerospace, navigation, and medical Application prospects. With the rapid development of the aviation industry, the requirements for the overall performance of the aircraft are getting higher and higher, and the demand for its components is also increasing. In order to meet the requirements of lightweight and lightweight aircraft, the structural parts of the aircraft, especially the load-be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G16C20/30G16C10/00G16C20/70G16C60/00C21D9/00C21D11/00C22F1/18G06F30/23G06F111/10G06F113/26G06F119/14G06F119/08

CPCG16C20/30G16C10/00G16C20/70G16C60/00C22F1/183C21D11/00C21D9/0075G06F30/23G06F2111/10G06F2119/14G06F2113/26G06F2119/08

Inventor 陈雷张启飞杨帅金淼贾伟谢静孙朝远莫安军崔明亮

Owner YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com