Rail transit cutting grinding wheel

A technology for cutting grinding wheels and rail transportation, which is applied in the field of grinding wheels, which can solve the problems of temperature rise, softness, waste, etc., and achieve the effects of increasing toughness and hardness, good cooling efficiency, and increasing heat resistance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

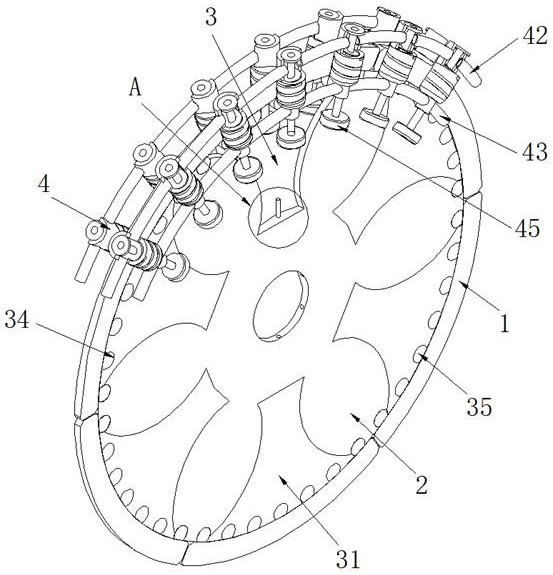

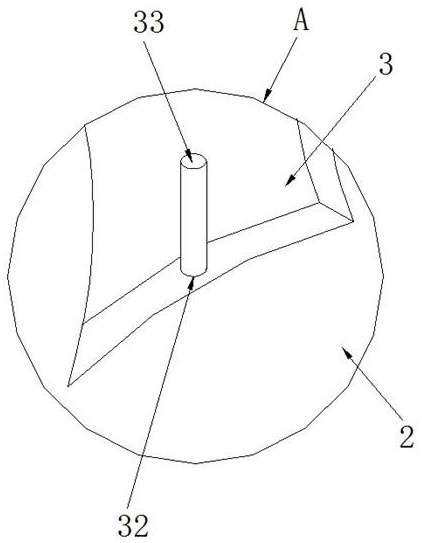

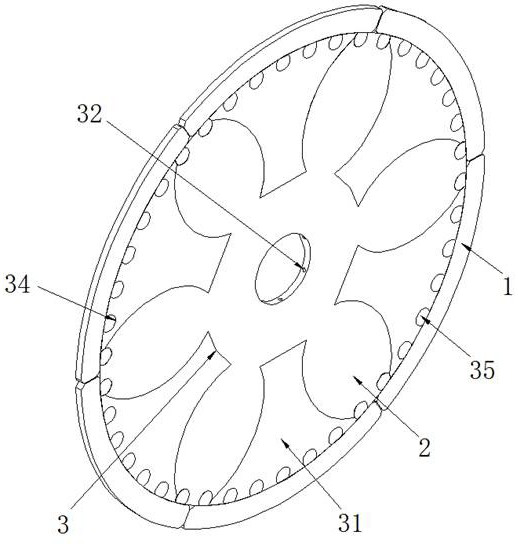

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0041] refer to Figure 1-4 , a cutting wheel for rail transit, comprising a basic abrasive composed of phenolic resin powder, corundum abrasive and silicon carbide abrasive;

[0042] The inside of the basic abrasive is also provided with cemented carbide abrasive and graphene abrasive.

[0043] Cemented carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which basically remain unchanged even at a temperature of 500°C , It still has a high hardness at 1000 °C, and it is applied to the cutting grinding wheel, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com