Wide flexible asbestos board layering and overturning system

A flexible asbestos and asbestos board technology, applied in the direction of destacking of objects, conveyors, conveyor objects, etc., to reduce the harm to human health, ensure stability, and improve general performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

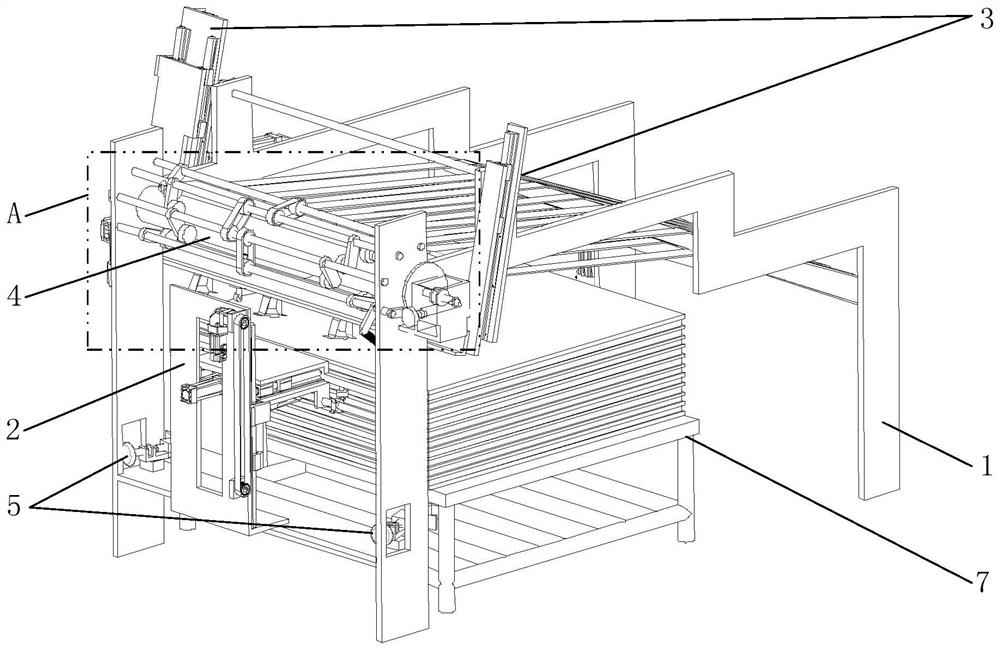

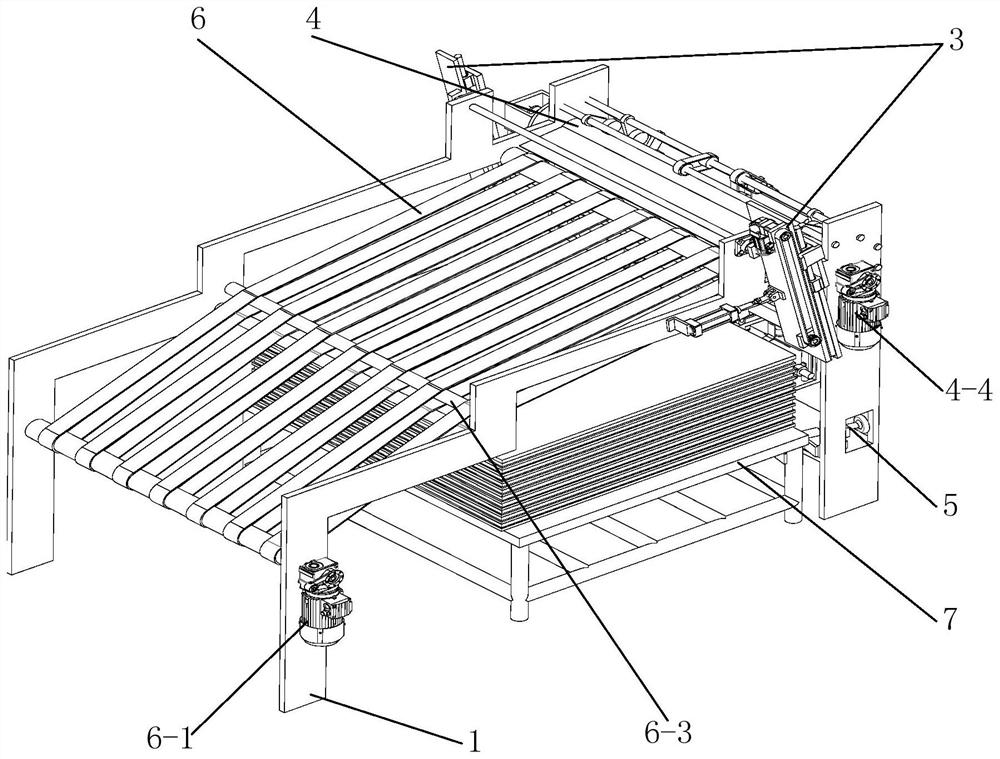

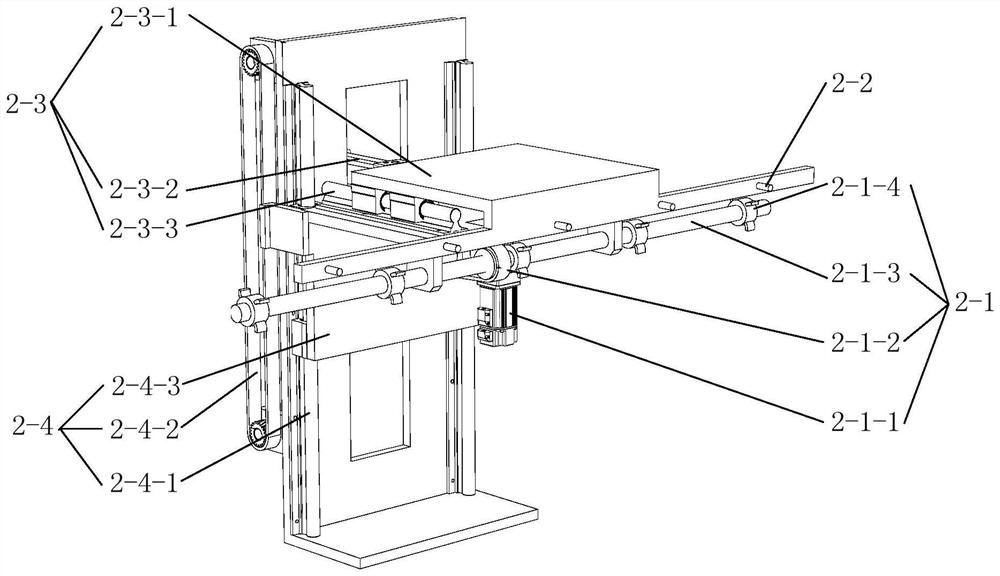

[0027] Such as Figure 1-2As shown, a wide-width flexible asbestos board layering and turning system includes a frame 1, a layering mechanism 2, a suction mechanism 3, a turning mechanism 4, a positioning mechanism 5, a conveying mechanism 6 and a control unit, and is characterized in that : the conveying mechanism 6 is fixedly connected to the upper layer of the frame 1, the suction mechanism 3 is hinged to both sides of the upper end of the frame 1, the turning mechanism 4 is connected to both sides of the frame 1, and the layering mechanism 2 is connected to the lower platform of the frame 1, And be positioned at the below of asbestos plate turnover mechanism 4, positioning mechanism 5 is positioned at the lower end of frame, and asbestos board pile is placed on the shelf 7 and is positioned at frame 1, fixes the relative position of shelf 7 and frame 1 by positioning mechanism 5, described The control unit detects the real-time height of the asbestos board stack, controls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com