A low energy consumption deep denitrification system for sewage

A deep denitrification, low energy consumption technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low treatment capacity, incomplete nitrogen removal, secondary pollution, etc. Achieve the effect of improving the efficiency of denitrification treatment, improving denitrification treatment and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

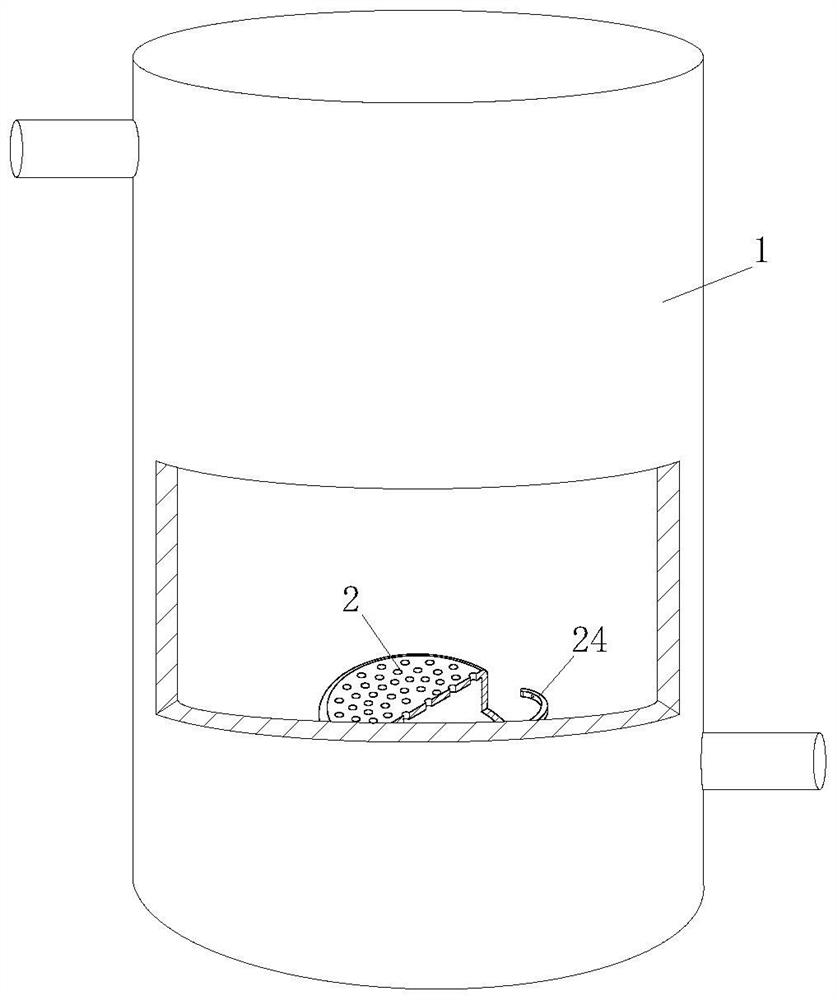

[0038] A low energy consumption deep denitrification system for sewage, as follows Figure 1-4 As shown, it includes a reaction device 1, a water inlet device, a water outlet device and an air pump for sewage denitrification reaction, and also includes:

[0039] a biofilm carrier, the biofilm carrier is arranged in the reaction device, and the biofilm carrier is used for inhabitation and growth and reproduction of microorganisms;

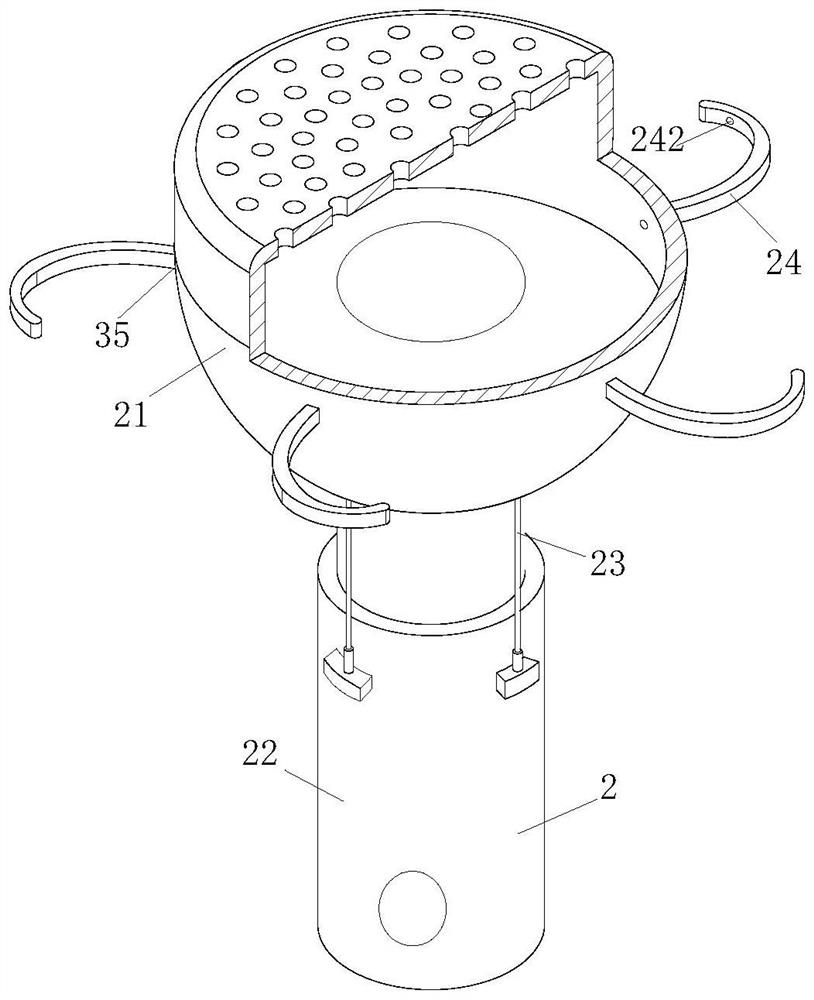

[0040] Aeration module 2, the aeration module 2 is communicated with the air pump, and the aeration module 2 is composed of an aeration head 21, an aeration pipe 22 and an adjustment unit 23, and the aeration head 21 is connected to the aeration head 21 through a ball joint. The end of the pipe 22, and one or more groups of air intake passages are opened on the ball joint, the adjustment unit 23 includes one or more of a cylinder or an electric push rod, and one end of the adjustment unit 23 is installed in the aeration pipe On the outer ring of 22...

Embodiment 2

[0046] The difference from Embodiment 1 lies in the following Figure 1-4 As shown, the end of the aeration pipe 22 is connected with a driving source, and the driving source is one or more of a motor or a rotating cylinder. The driving source is used to drive the aeration pipe 22 to rotate. A swivel ring is sleeved, and a through air inlet hole 221 is opened between the swivel ring and the aeration pipe 22, and the air inlet hole 221 is communicated with the air pump through a hose;

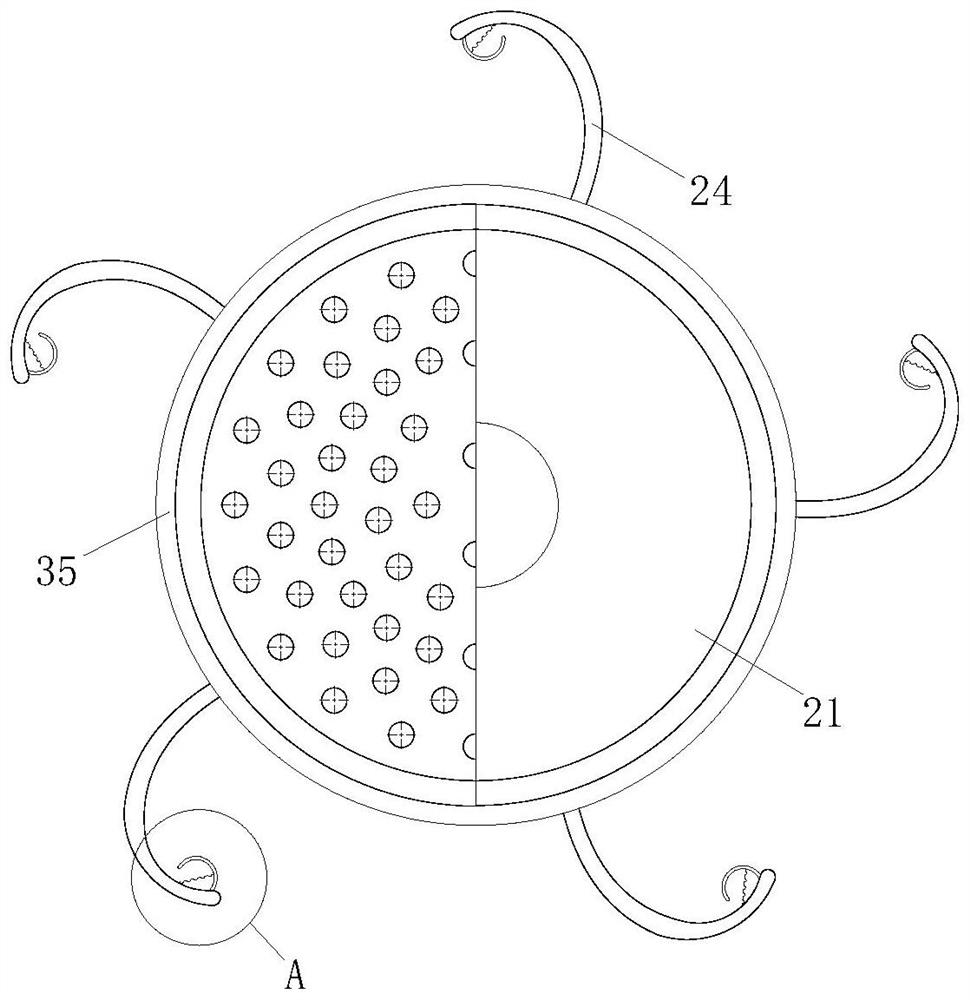

[0047] The outer ring of the aeration head 21 is evenly provided with arc-shaped blades 24, the arc-shaped blades 24 are bent toward the side close to the aeration head 21, and the thickness of the middle of the arc-shaped blades 24 gradually decreases toward both sides.

[0048] The driving source drives the aeration pipe 22 to rotate, so that the aeration head 21 rotates, so that when the gas bursts through the aeration head 21, a vortex can be formed, so that the large bubbles generated when ...

Embodiment 3

[0053] The difference from the second embodiment is as follows Figure 4 and Image 6 As shown, the interior of the arc-shaped blade 24 is provided with an air passage 241, one end of the air passage 241 is communicated with the interior of the aeration head 21, and the other end is communicated with the opening 242 opened on the arc-shaped blade 24. The opening 242 is located at one end of the arc-shaped blade 24 away from the aeration head 21 .

[0054] By setting the air passage one 241 on the arc-shaped blade 24, the gas is ejected from the air passage one 241. At the same time, because the arc-shaped blade 24 rotates with it, the area where the gas acts is larger, and the spray of the aeration head 21 is reduced. The time wasted by the outgoing gas acting from top to bottom, thus improving the efficiency of denitrification treatment of sewage;

[0055] Specific workflow:

[0056] The difference from the specific working process of the second embodiment is that when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com