Composite concrete self-repairing material and application thereof, and preparation method of self-repairing concrete

A self-healing material and concrete technology, applied in the field of concrete, can solve problems such as low self-healing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

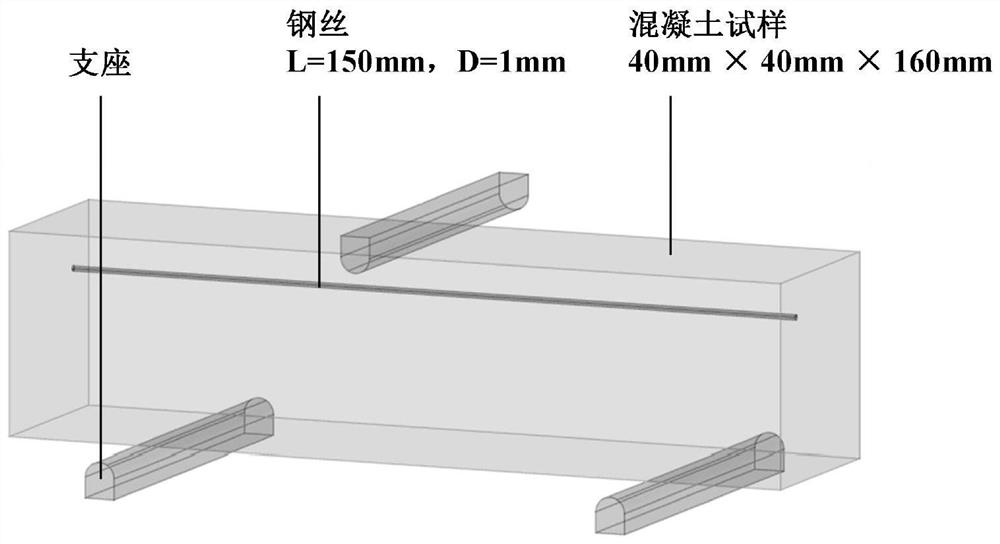

Image

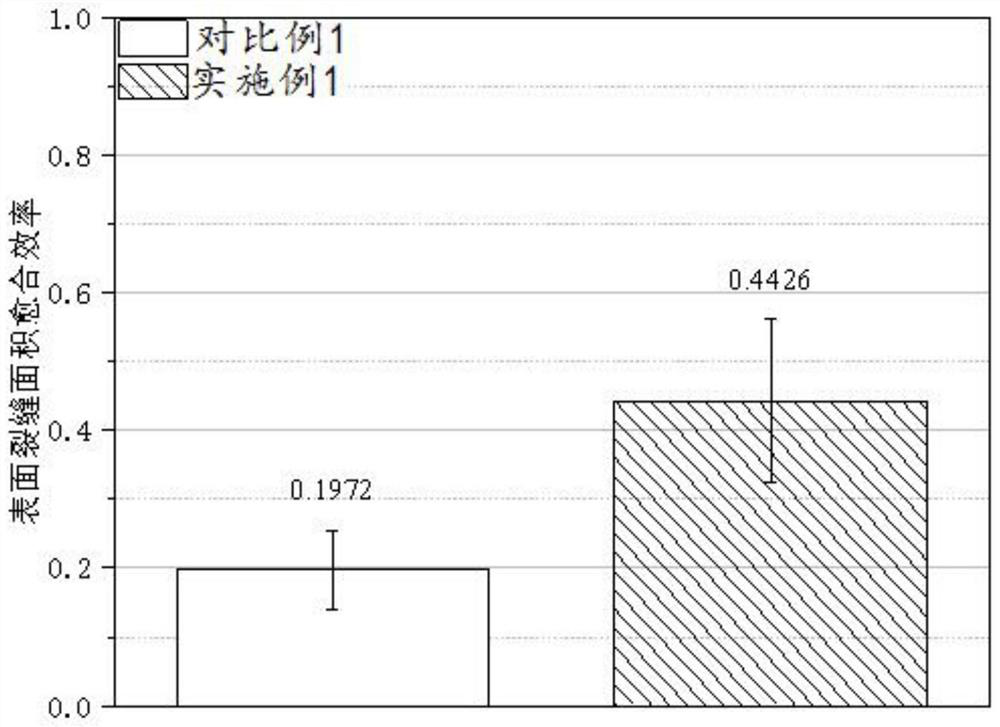

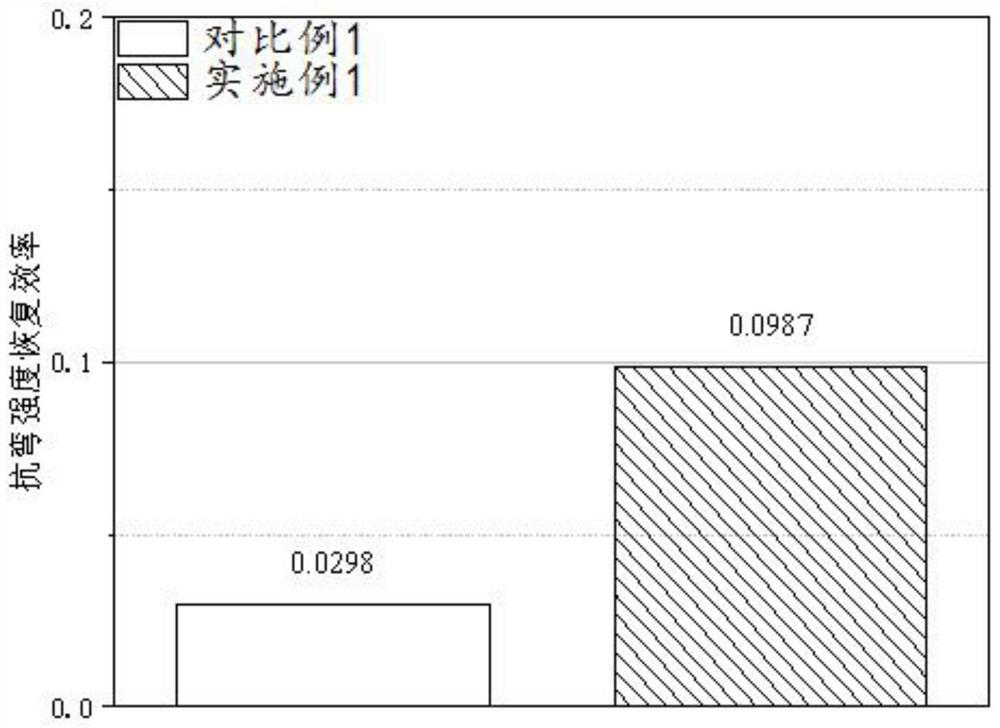

Examples

preparation example Construction

[0028] The composite concrete self-repairing material provided by the invention includes carbonate light aggregate. In the present invention, the carbonate light aggregate preferably comprises lightweight aggregate and carbonate attached to the surface and pores of the lightweight aggregate; the preparation method of the carbonate light aggregate preferably comprises the following steps: The lightweight aggregate is soaked in the carbonate solution for 24 hours, and then dried; the present invention has no special limitation on the drying process, and the drying process well known in the art can be adopted. In the present invention, the lightweight aggregate is preferably clay ceramsite; the particle size of the lightweight aggregate is preferably 3-8mm; the natural water absorption of the lightweight aggregate is preferably 9.4-11.3%, more preferably 10 ~11%; The massfraction of described carbonate solution is preferably 10~20%, more preferably 10~15%; Described carbonate pre...

Embodiment 1

[0046] Fully mix 300g of sodium carbonate and 2700g of deionized water to prepare a sodium carbonate solution with a mass concentration of 10%. Soak 50g of lightweight aggregate (3-8mm, water absorption rate of 10.5%) in the sodium carbonate solution for 24 hours to make the lightweight aggregate fully Absorb sodium carbonate solution to obtain carbonate light aggregate;

[0047] Mix 86.5g of cement, 10g of calcium sulfoaluminate-based expansion agent (3-4μm), 2g of crystalline additive (18-20μm, calcium oxide, magnesium oxide and silicon dioxide in a mass ratio of 2:1:1), 1.5g di Calcium hydrogen phosphate water (8-10μm) and 0.5g sodium acrylate water-absorbing resin (520-530μm) are added to the stirring pot, and the speed of the stirring blade is adjusted to 140r / min to fully stir for 1min, and then add 200g of standard sand (0.16-1.25mm ) and 50g of carbonate light aggregate and maintain the speed of the stirring blade at 140r / min and fully stir for 4min. At the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com