Low-consumption stone-like coating and preparation method thereof

A technology of real stone paint and consumption, applied in the field of coatings, can solve the problems of the inability to guarantee the supply of real stone paint color sand, the increase of labor costs, the reduction of profits of the constructor and the general contractor, etc. The effect of changing, improving water retention performance and thixotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of low-consumption real stone paint, the concrete steps are as follows:

[0033] (1) Put some water into the dispersion tank, adjust to 500-700 rpm, then add hydroxyethyl cellulose, and disperse for 3-5 minutes;

[0034] (2) Then adjust the rotating speed to 700-1000 rpm, add multifunctional additives, and disperse for 3-5 minutes;

[0035] (3) Then keep the rotation speed at 700-1000 rpm, then put in pure acrylate emulsion, disperse for 3-5 minutes, adjust the rotation speed to 500-700 rpm, then add bactericidal preservatives, freeze-thaw stabilizers, synthetic Membrane aid and alkali swelling thickener, continue to disperse for 3-5 minutes;

[0036] (4) Continue to maintain 500-700 rpm, put in 0.2-4.0 parts of PH regulator, 10.0-40.0 parts of silica sol, 20.0-90.0 parts of styrene-acrylic emulsion, 40-60 parts of slip agent, 1-2 parts of antifreeze , 1-2 parts of water-based defoamer, and then continue to disperse for 3-5 minutes.

[0037] (5) ...

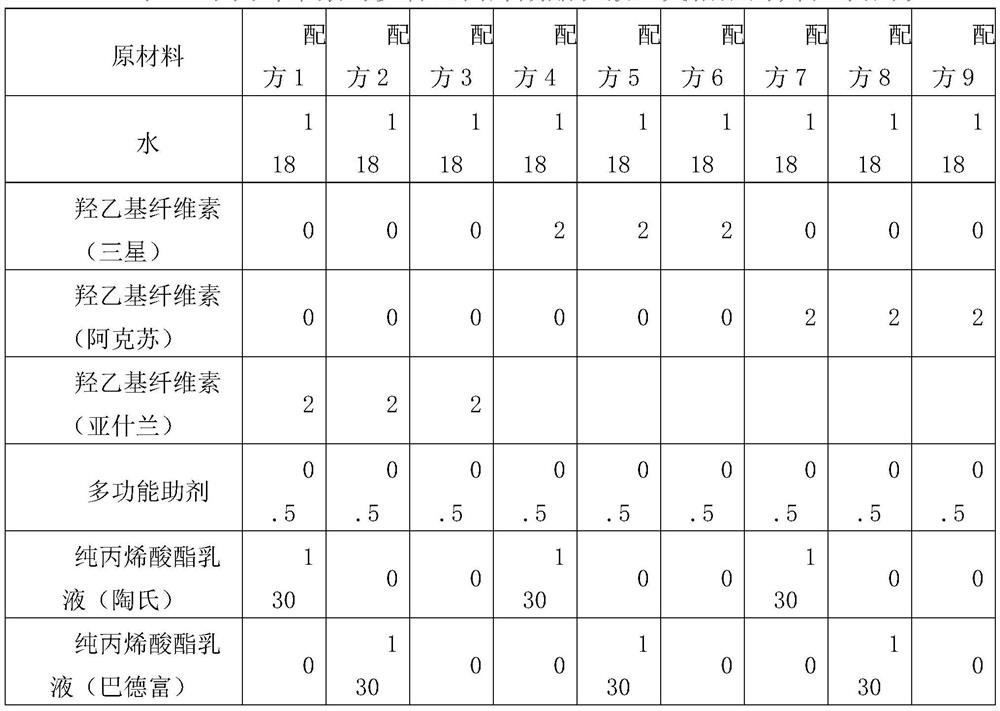

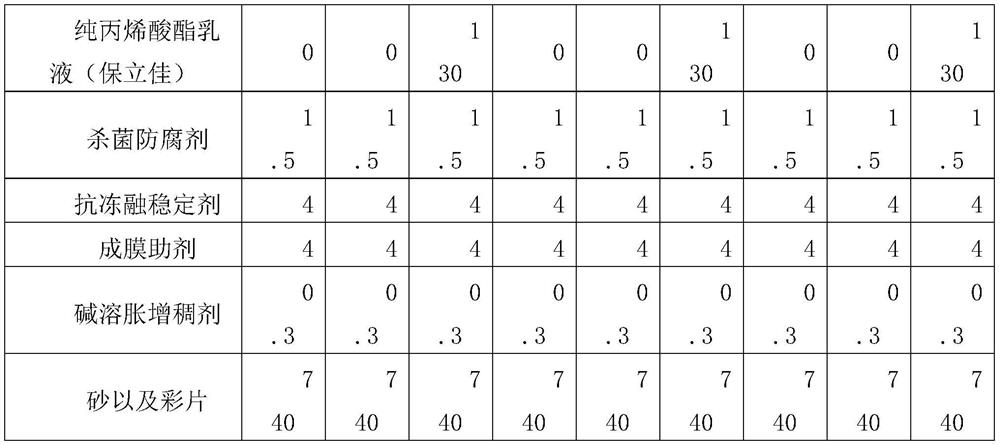

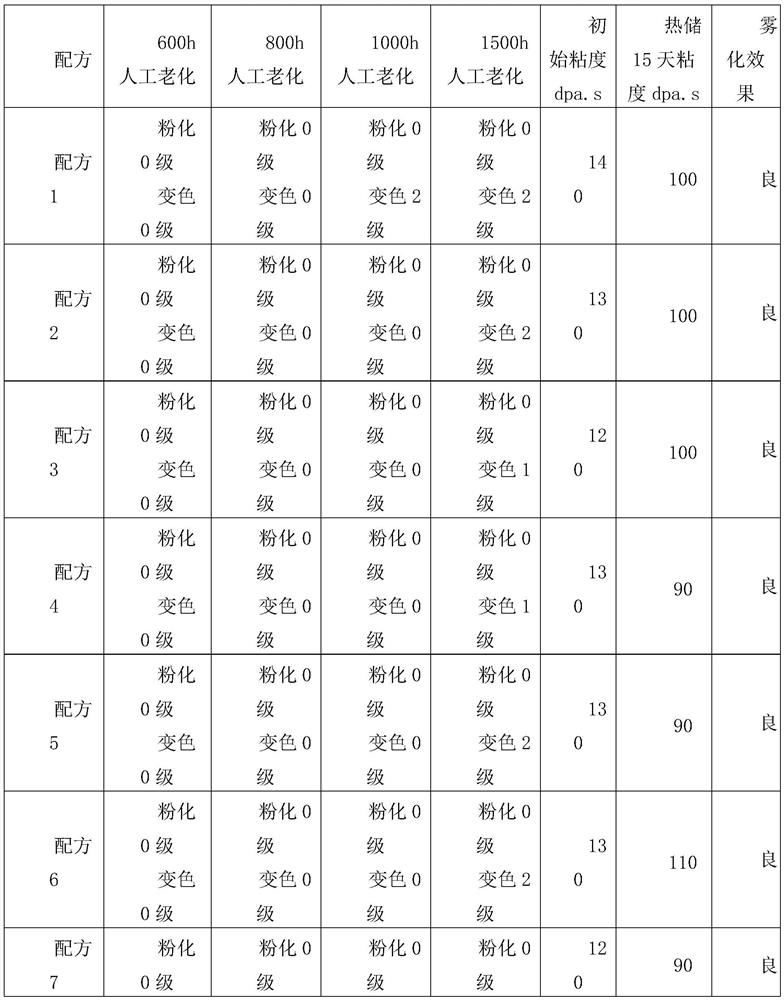

Embodiment 1

[0039] In order to achieve a good spraying atomization effect, stable storage performance and excellent temperature-varying color difference performance, in this embodiment 1, a variety of hydroxyethyl cellulose and a variety of acrylate emulsions in the low-consumption real stone paint formula are selected to be orthogonally matched The screened schemes are respectively numbered "Formulation 1", "Formulation 2" ... "Formulation 9", prepared according to the components and mass / number ratios shown in Table 1:

[0040] Table 1 Real stone paint formulations with different celluloses and various pure acrylate emulsions

[0041]

[0042]

[0043] The preparation method of the low consumption real stone paint of this implementation is according to the following steps:

[0044] (1) Put water into the dispersion tank, adjust to 500 rpm, then add hydroxyethyl cellulose, and disperse for 5 minutes;

[0045] (2) Then adjust the rotation speed to 700 rpm, add multifunctional addit...

Embodiment 2

[0056] In order to further optimize the storage performance of the formula, in Example 2, the cellulose in the low-consumption real stone paint formula was selected for gradient comparison testing, respectively numbered "Formula 10" to "Formula 13", and the components shown in Table 3 Formulated with the ratio of parts by mass:

[0057] Table 3 Different Gradient Formulas Containing Cellulose

[0058]

[0059] The preparation method of the low consumption real stone paint of the present embodiment is according to the following steps:

[0060] (1) Put water into the dispersion tank, adjust to 700 rpm, then add hydroxyethyl cellulose, and disperse for 3 minutes;

[0061] (2) Then adjust the rotation speed to 1000 rpm, add multifunctional additives, and disperse for 3 minutes;

[0062] (3) Keep the rotation speed at 1000 rpm, then put in pure acrylate emulsion, adjust the rotation speed to 700 rpm after dispersing for 3 minutes, then add bactericidal preservative, freeze-tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com