A kind of alkylphenol modified phenolic amide curing agent and preparation method thereof

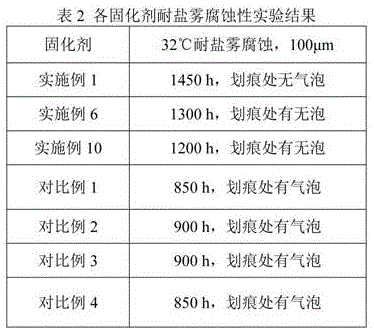

A technology of phenolic amide and curing agent, which is applied in the field of alkylphenol-modified phenolic amide curing agent and its preparation, can solve the problems of easy yellowing, poor impact resistance, etc. Long, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

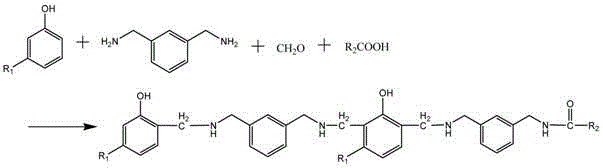

Method used

Image

Examples

Embodiment 1

[0040] An alkylphenol-modified phenalkamide curing agent, the raw materials of which are 150.0 g of cardanol, 20.6 g of paraformaldehyde, 94.7 g of triethylenetetramine, and 66.4 g of tall oleic acid.

[0041] The preparation method of above-mentioned alkylphenol modified phenolic amide solidifying agent, comprises the steps:

[0042] Take tall oleic acid and triethylenetetramine, stir evenly, heat up to 200°C, keep warm for 3 hours, after the reaction, cool down to 50°C, add cardanol and paraformaldehyde, heat up to 120°C, keep warm for 3 hours , and then heated up to 150°C for dehydration for 30 minutes, and steamed out without water to obtain a curing agent product, also known as cardanol modified phenalkamide curing agent.

Embodiment 2

[0044] An alkylphenol-modified phenalkamide curing agent, the raw materials of which are 165.0 g of cardanol, 20.6 g of paraformaldehyde, 75.7 g of triethylenetetramine, 7.4 g of m-xylylenediamine, and 59.0 g of tall oleic acid.

[0045] The preparation method of above-mentioned alkylphenol modified phenolic amide solidifying agent, comprises the steps:

[0046] Take tall oleic acid, triethylenetetramine, m-xylylenediamine, stir evenly, heat up to 200°C, keep warm for 3 hours, after the reaction, cool down to 50°C, add cardanol, paraformaldehyde, heat up to 110°C ℃, heat preservation reaction for 3 h, then heated up to 150°C for dehydration for 30 min, cooled to 60°C, added 6.2 g of DMP-30, and stirred evenly to obtain a curing agent product, also known as cardanol modified phenalkamide curing agent.

Embodiment 3

[0048] An alkylphenol-modified phenalkamide curing agent, the raw materials of which are 172.5 g of cardanol, 19.8 g of paraformaldehyde, 89.4 g of polyethylene polyamine, 17.0 g of m-xylylenediamine, and 73.8 g of tall oil.

[0049] The preparation method of above-mentioned alkylphenol modified phenolic amide solidifying agent, comprises the steps:

[0050]Take tall oleic acid, polyvinylpolyamine, m-xylylenediamine, stir evenly, heat up to 200°C, keep warm for 3 hours, after the reaction, cool down to 50°C, add cardanol, paraformaldehyde, heat up to 110°C ℃, heat preservation reaction for 3 hours, then lower the temperature to 73℃, vacuum dehydrate until no water is evaporated, lower the temperature to 60℃, add 6.5 g of DMP-30, stir well, and obtain the curing agent product, also known as cardanol modified phenalkamide curing agent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com