Powder coating with high-temperature-yellowing-resistant function

A technology for powder coatings and high temperature resistance, applied in powder coatings, fireproof coatings, polyester coatings, etc., can solve the limitations of the application and marketing of hydroxyalkylamide curing agents, poor heat resistance, yellowing resistance, and pinholes and other problems, to achieve good sun protection performance, long-term stability and aging resistance, and not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 4-Hydroxyphenylboronic acid pinacol ester: CAS: 269409-70-3, from Shanghai Xianding Biotechnology Co., Ltd.;

[0029] 2',5-dichloro-2-hydroxybenzophenone: CAS:61785-35-1, from Shanghai Xianding Biotechnology Co., Ltd.;

[0030] Ethyl 4-chlorobenzoate: CAS: 7335-27-5, from Shanghai Xianding Biotechnology Co., Ltd.

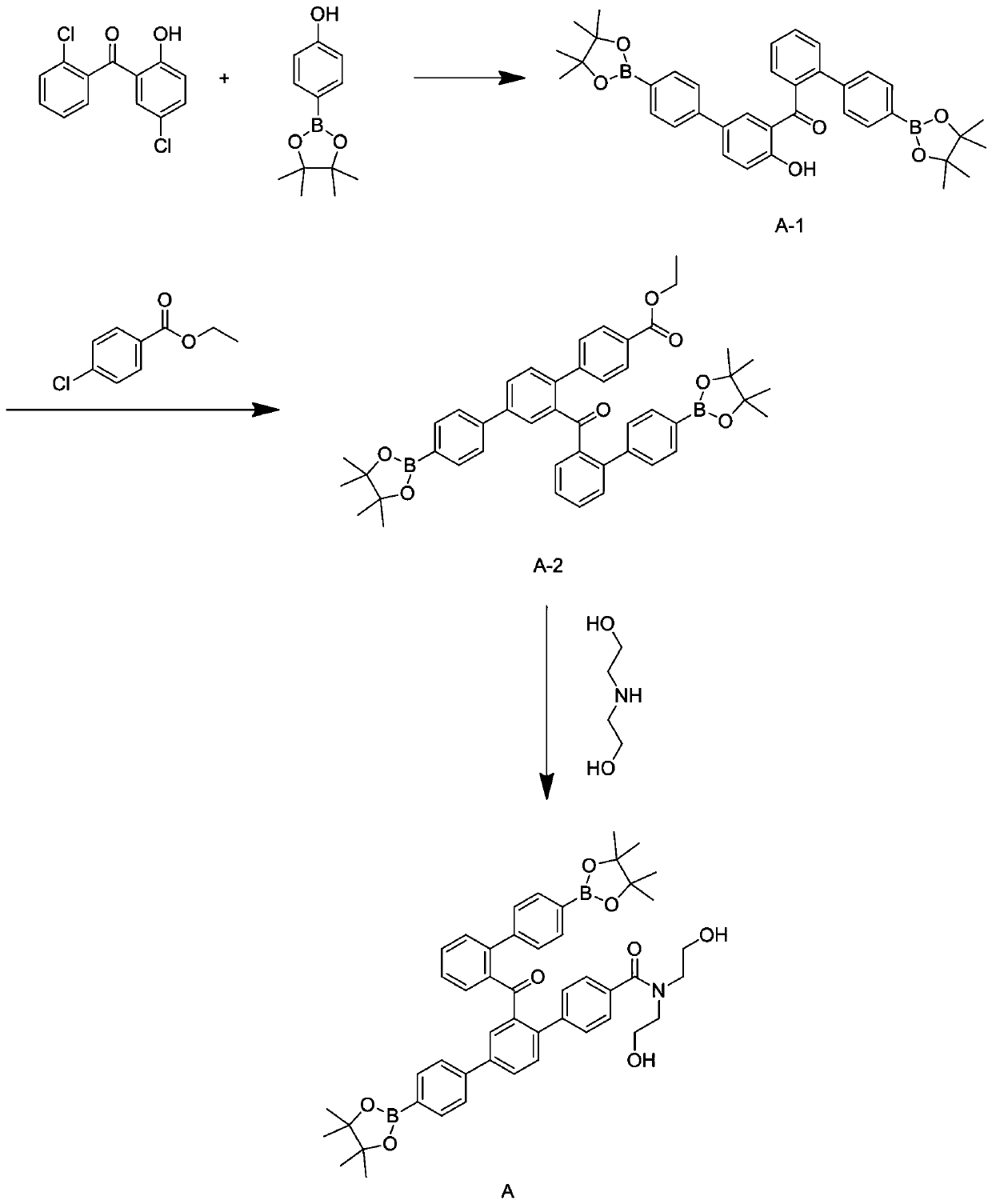

[0031] see figure 1 Shown, the synthetic method of modified bishydroxyalkylamide curing agent specifically comprises the following steps:

[0032] The first step is to add 2.05mol 4-hydroxyphenylboronic acid pinacol ester and 32g cesium carbonate to the reaction kettle, then add 12L tetrahydrofuran, stir at room temperature for 30min, after the dissolution is complete, add 1mol 2',5-dichloro -2-Hydroxybenzophenone was slowly poured into the reaction kettle, and the addition was completed within 15 minutes. Then, the temperature was raised to 100°C while stirring, and stirred and refluxed for 14 hours. After the reaction, cooled to room temperature, the crud...

Embodiment 2

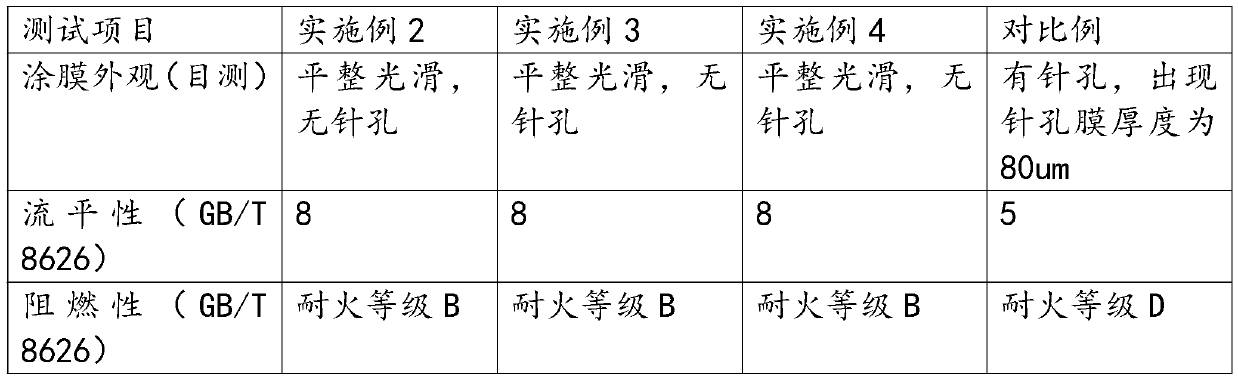

[0038] A powder coating with high temperature yellowing resistance, comprising the following raw materials in parts by weight: 60 parts of polyester resin, 3 parts of curing agent, 1 part of smoothing and degassing agent, 1 part of leveling agent, and 30 parts of pigments and fillers;

[0039] The mass ratio of tetrafunctional hydroxyalkylamide curing agent and modified bishydroxyalkylamide curing agent in the curing agent is 17:20;

[0040] The preparation method of the powder coating is as follows: put the raw materials into the mixing tank according to the above ratio, and pre-mix for 5 minutes*3 times; then extrude and tablet on the extruder. The second zone is 115°C, and then the flakes are crushed for fine grinding, and the coarse powder is passed through a rotary sieve to obtain a fine powder of 20-50 microns as the final powder coating.

Embodiment 3

[0042] A powder coating with high temperature yellowing resistance, comprising the following raw materials in parts by weight: 58 parts of polyester resin, 2.5 parts of curing agent, 2 parts of smoothing and degassing agent, 2 parts of leveling agent, and 40 parts of pigment and filler;

[0043] The mass ratio of tetrafunctional hydroxyalkylamide curing agent and modified bishydroxyalkylamide curing agent in the curing agent is 15:20;

[0044] The preparation method of the powder coating is as follows: put the raw materials into the mixing tank according to the above ratio, and pre-mix for 5 minutes*3 times; then extrude and tablet on the extruder. The temperature in the second zone is 113°C, and then the flakes are crushed for fine grinding, and the coarse powder is passed through a rotary sieve to obtain a fine powder of 20-50 microns as the final powder coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com