Spraying waterborne wood primer and preparation method thereof

A water-based, wood-based technology, applied in the coating and other directions, can solve the problems of pinholes and good adhesion of the paint film, and achieve the effects of fast drying speed, good adhesion and good sandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

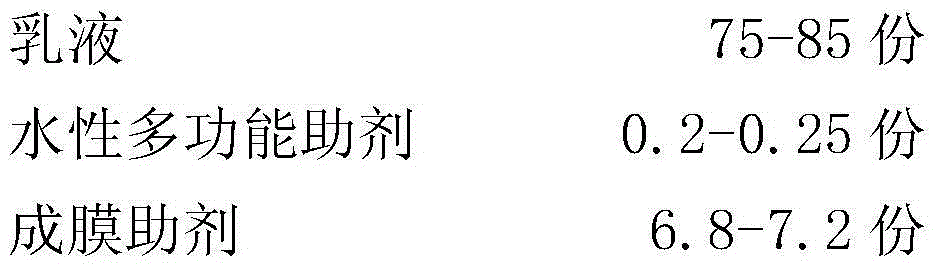

[0023] A spray-coated water-based wood primer formulated from the following components and weight / number ratios:

[0024]

[0025] The emulsions are pure acrylate copolymers.

[0026] A kind of preparation method of the waterborne wood primer of spraying, it comprises the steps:

[0027] Add 75-85 parts of emulsion into the dispersion tank, and add 0.2-0.25 parts of water-based multifunctional additives, 6.8-7.2 parts of film-forming additives, 0.2-0.3 parts of defoamers, 0.4- 0.5 parts of substrate wetting agent, 0.8-1.0 parts of antifreeze, 0.1-0.2 parts of preservative, 0.8-1.2 parts of thickener and 4.9-15.1 parts of water, after dispersing for 20-30 minutes, the sprayed water-based wood primer can be obtained .

[0028] The emulsion described in the above components adopts the W-2010 emulsion of Bardford. The water-based multifunctional additive adopts Dow's AMP-95 multifunctional additive. The film-forming aid adopts DPNB or DPM film-forming aid of Eastman Chemica...

Embodiment 1

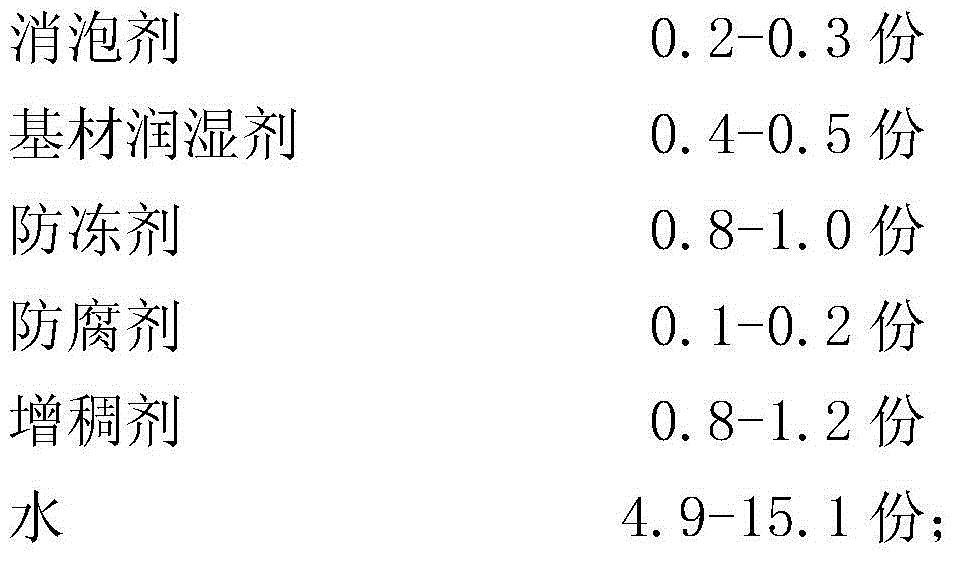

[0030] Embodiment 1: a kind of sprayed water-based wood primer is prepared from the following components and parts by weight ratio:

[0031]

[0032] The emulsions are pure acrylate copolymers.

[0033] A kind of preparation method of the waterborne wood primer of spraying, it comprises the steps:

[0034] Put 85 parts of emulsion into the dispersion tank, add 0.25 parts of water-based multifunctional additives, 7.2 parts of film-forming additives, 0.25 parts of defoamers, 0.5 parts of substrate wetting agents, and 1.0 parts of antifreeze at a speed of 1000r / min , 0.1 part of preservative, 0.8 part of thickener and 4.9 parts of water, after dispersing for 20 minutes, the water-based wood primer for spraying was obtained.

[0035] The emulsion described in the above components adopts the W-2010 emulsion of Bardford. The water-based multifunctional additive adopts Dow's AMP-95 multifunctional additive. The film-forming aid adopts the DPNB film-forming aid of Eastman Chemic...

Embodiment 2

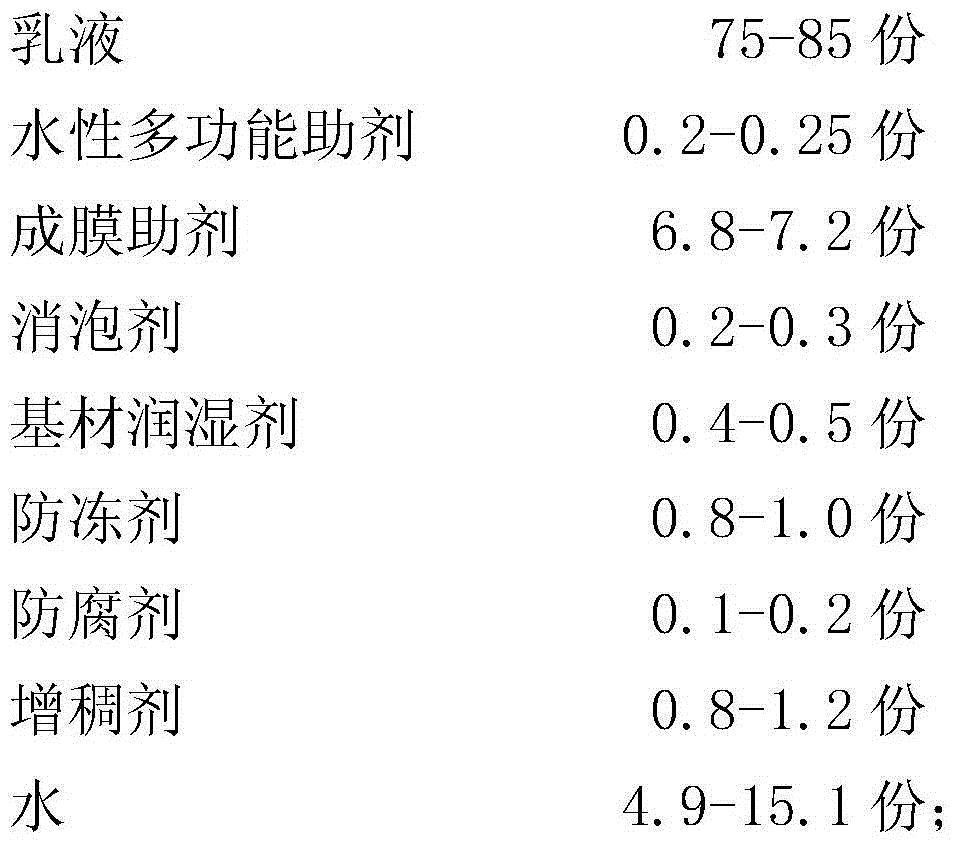

[0036] Embodiment 2: a kind of waterborne wood primer of spraying, is formulated by following component and weight and number ratio:

[0037]

[0038]

[0039] The emulsions are pure acrylate copolymers.

[0040] A kind of preparation method of the waterborne wood primer of spraying, it comprises the steps:

[0041] Add 75 parts of the emulsion into the dispersion tank, add 0.2 parts of water-based multifunctional additives, 6.8 parts of film-forming additives, 0.2 parts of defoamers, 0.5 parts of substrate wetting agents, and 0.8 parts of antifreeze at a speed of 800 r / min , 0.2 parts of antiseptic, 1.2 parts of thickener and 15.1 parts of water, after dispersing for 30 minutes, the water-based wood primer for spraying was obtained.

[0042] The emulsion described in the above components adopts the W-2010 emulsion of Bardford. The water-based multifunctional additive adopts Dow's AMP-95 multifunctional additive. The film-forming aid adopts the DPNB film-forming aid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com