Buried agricultural corn straw fermentation equipment

A technology of corn stalks and fermentation equipment, which is applied in the direction of biochemical equipment and methods, bioreactor/fermentation tank combination, specific-purpose bioreactor/fermentation tank, etc., which can solve the problem of high investment cost and cumbersome fermentation treatment steps of straw resources and other problems to achieve the effects of improving fermentation efficiency, avoiding high water content, and facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

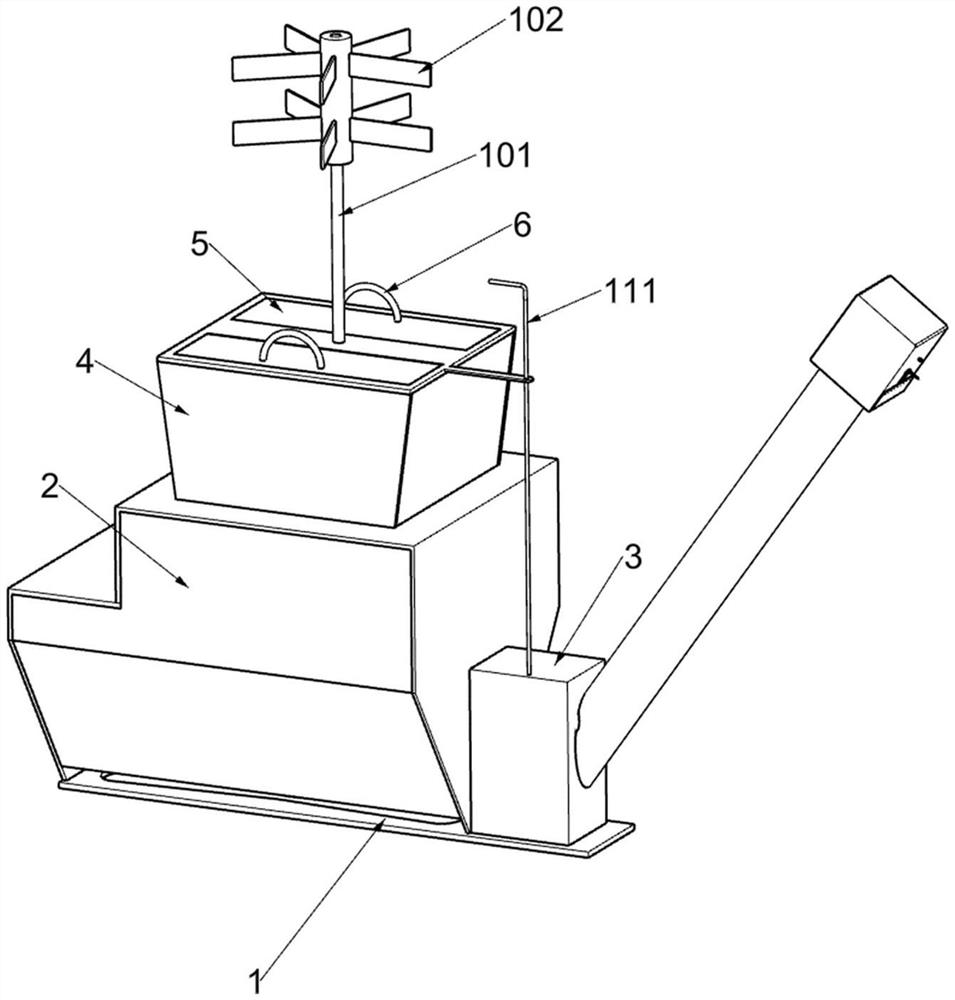

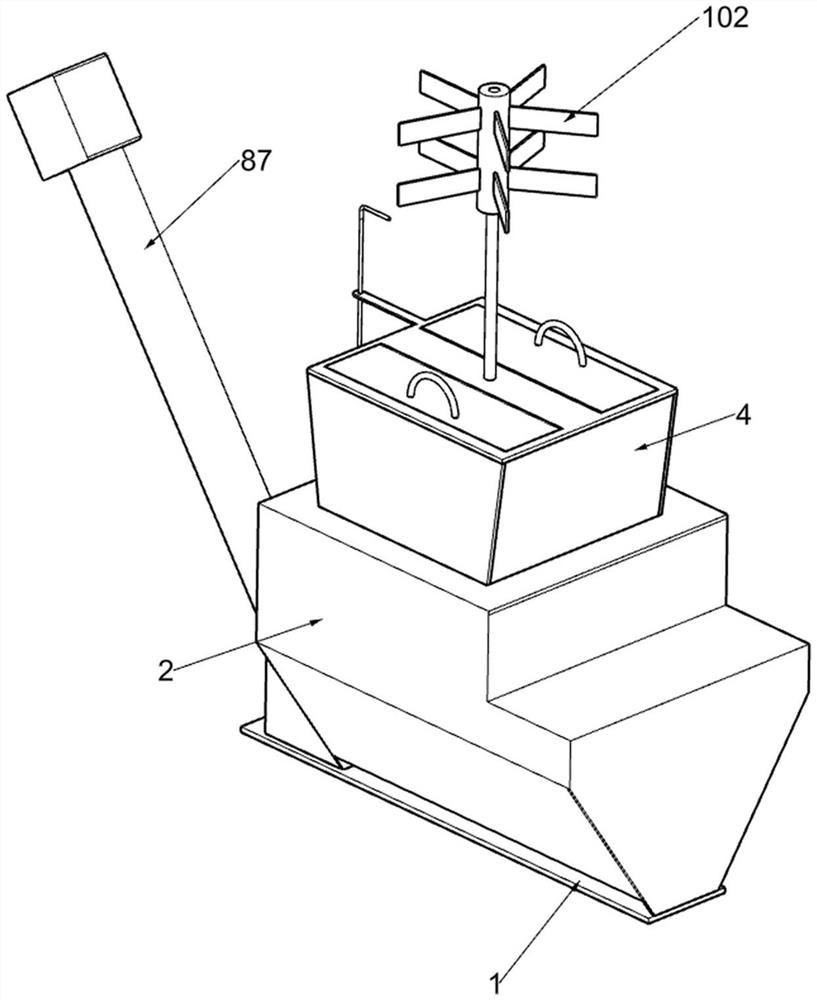

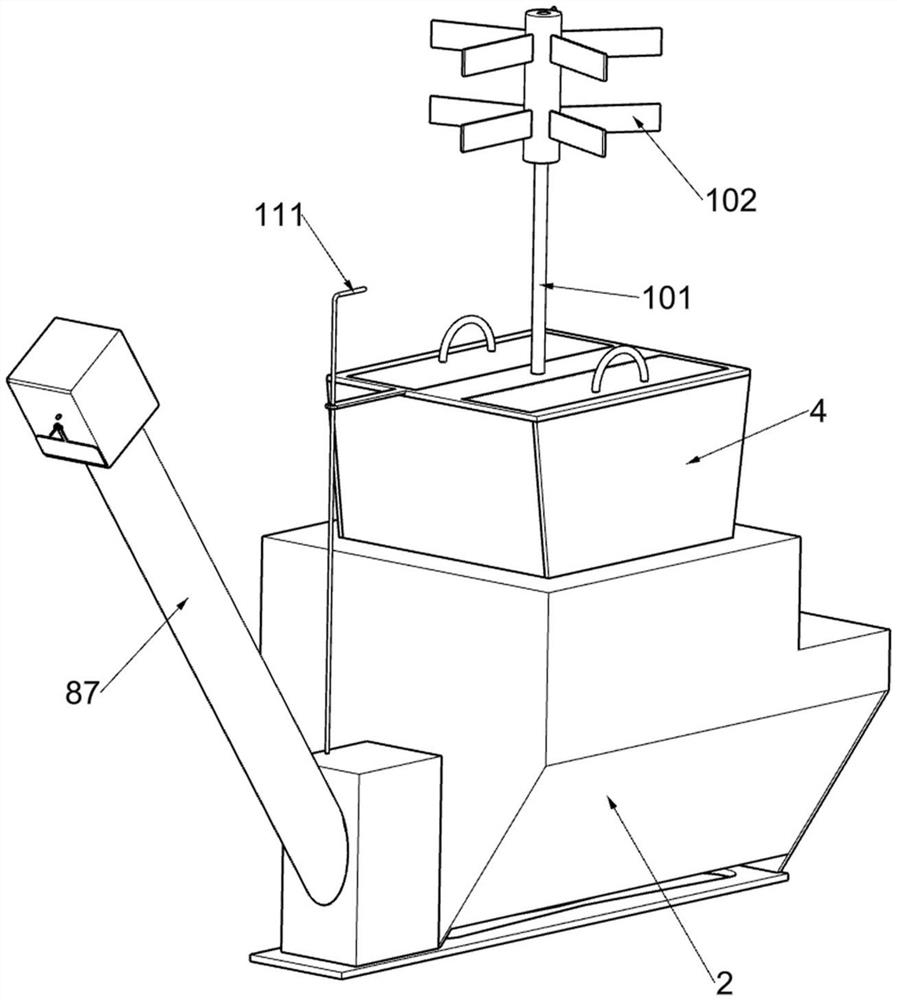

[0043] A buried agricultural corn stalk fermentation equipment, such as Figure 1-11 As shown, it includes a bottom plate 1, an installation shell 2, a square frame 3, a fermentation frame 4, a movable sealing plate 5, a pull ring 6, a power opening and closing component 7, and a feeding component 8, and the top surface of the bottom plate 1 is fixedly installed with an installation shell The body 2 and the square frame 3 are also fixedly installed on the top surface of the bottom plate 1, the installation shell 2 is fixedly connected to the square frame 3, the fermentation frame 4 is fixedly installed on the installation shell 2, and the top of the fermentation frame 4 is slidably connected with two movable sealing plates 5. The top surface of the movable sealing plate 5 is fixedly connected with a pull ring 6 for manual pulling, the power opening and closing component 7 is set in the installation shell 2, and the feeding component 8 for transporting fermentation products is s...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 12 As shown, an anti-caking assembly 9 is also included. The fermentation frame 4 is provided with an anti-caking assembly 9. The anti-caking assembly 9 is used to prevent the fermentation product from caking. The anti-caking assembly 9 includes a fixed guide rod 91, a moving Guide rod 92, mobile rack 93, fixed round rod 94, fixed rack 95, mounting plate 96, opposite gear 97 and moving rack 98, fixed guide rod 91 is welded on fermentation frame 4 side, on the reciprocating screw rod 72, connect by thread The mode is connected with moving guide rod 92, and fixed guide rod 91 is connected with sliding type with moving guide rod 92, and two movable racks 93 are slidingly connected in fermentation frame 4, and two movable racks 93 are in contact with each other, and one movable rack 93 is connected with movable guide rod. The rod 92 is fixedly connected, and the mobile frame 93 is connected with fixed round rods 94 in a uniform arr...

Embodiment 3

[0053] On the basis of Example 2, such as Figure 13-14 As shown, it also includes a wind agitation assembly 10, the fermentation frame 4 is provided with a wind agitation assembly 10, the wind agitation assembly 10 is used to use wind energy to stir the corn stalks and bacteria, the wind agitation assembly 10 includes a wind shaft 101, a wind Power pushing frame 102, transverse rod 103, square housing 104, stirring rod 105 and bevel gear 106, the wind power shaft 101 is connected with the rotation type on the fermentation frame 4, and the wind power pushing frame 102 is fixedly connected above the wind power shaft 101, and the fermentation frame 4 There are two transverse bars 103 fixedly connected inside, and a square shell 104 is welded together on the bottom of the two transverse bars 103. The square shell 104 is rotationally connected with the wind shaft 101 far away from the wind pushing frame 102, and the square shell 104 is symmetrically rotationally connected. There i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap