Long-acting corrosion inhibition cooling liquid supply device for cutting machine tool

A technology of cutting machine tools and supply devices, which is applied in the field of workpiece processing, can solve the problems of general anti-corrosion effect of coolant, no corrosion inhibition effect, and body rust, etc., and achieve long-term anti-corrosion effect, long-term stability, and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The preparation method of the corrosion-inhibiting coolant selected in the present invention is as follows:

[0082] 1) According to the mass ratio of 2:0.5:1:1:4, mix aluminum powder with a particle size of 30 μm, silicon dioxide with a particle size of 10 μm, polyisobutenyl succinimide, and ethylenediamine phosphate, and then add it to liquid paraffin In, stir evenly and join in the grinding machine, the ball material ratio is 8:1, grind 10min with the rotating speed of 2000r / min, make composite particle;

[0083] 2) According to the mass volume ratio of 1:200g / mL, add the composite particles into the sodium hydroxide solution with a concentration of 0.1mol / L, stir and disperse at a speed of 100r / min for 5min, and then add fluorine p-aminobenzenesulfonate Borate diazonium salt, control the mass ratio of aminobenzenesulfonic acid fluoroborate diazonium salt and composite particles to 0.5:1, continue to stir for 20 minutes, add dilute hydrochloric acid to the filtrate a...

Embodiment 1

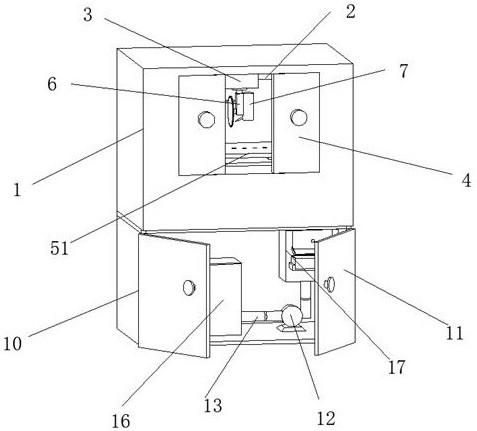

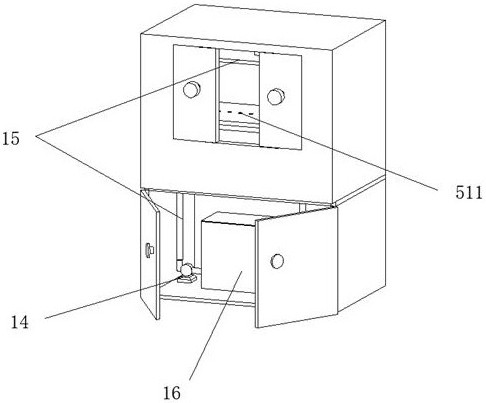

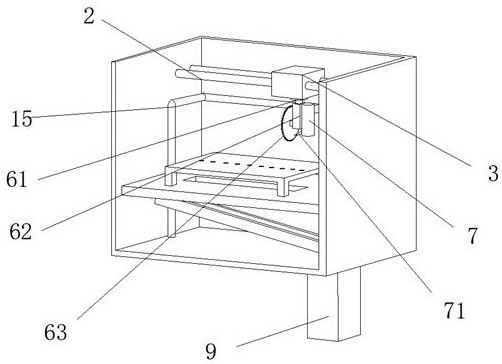

[0095] see Figure 1-6 , a long-term corrosion-inhibiting coolant supply device for cutting machine tools proposed by the present invention, comprising a cutting box 1, a sliding door 4 is slidably installed on the front surface of the cutting box 1, and a guide is fixedly connected to the inner wall of the cutting box 1. Rod 2, sliding table 3 is installed on the guide rod 2, and cutting mechanism 6 is installed on the sliding table 3, and the below of cutting mechanism 6 is provided with dividing plate 5, and dividing plate 5 is fixed on the inwall of cutting box 1.

[0096] Above-mentioned cutting mechanism 6 comprises hydraulic cylinder 61, and hydraulic cylinder 61 is fixedly connected with the lower end surface of slide table 3, and the telescoping end of hydraulic cylinder 61 is fixedly connected with mounting base 62, and cutting wheel 63 is installed on mounting base 62.

[0097] A liquid spraying mechanism 7 is also installed on the cutting mechanism 6 , and the liqu...

Embodiment 2

[0111] In order to facilitate the removal of metal scraps retained on the filter screen, embodiment 2 is based on embodiment 1 and a cleaning mechanism is added above the filter screen, which will be described in detail below.

[0112] The same part of embodiment 2 and embodiment 1 will not be described again, the difference is that

[0113] see Figure 7-9 Above the middle frame 51 and on the inner wall of the filtrate box 17, an external driving device is provided. The external driving device includes a side slider 224 arranged above the middle frame 20, and a reciprocating screw rod 225 is threaded through the side slider 224. A motor 226 is fixedly connected to the inner wall of the filtrate box 17, and the output shaft of the motor 226 is fixedly connected to the reciprocating screw rod 225 coaxially.

[0114] The middle frame 20 is provided with a cleaning mechanism 22, the cleaning mechanism 22 includes a top side plate 221, and the top side plate 221 is fixedly instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com