Bucket lifting type mixing plant aggregate lifting system

A lifting system and mixing station technology, which is applied in mixing plants, batching weighing instruments, and sales of raw material supply devices, etc., can solve problems such as large lifting motor power, broken lifting ropes, and falling of lifting buckets, so as to prolong the service life. The effect of reducing lifting time and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

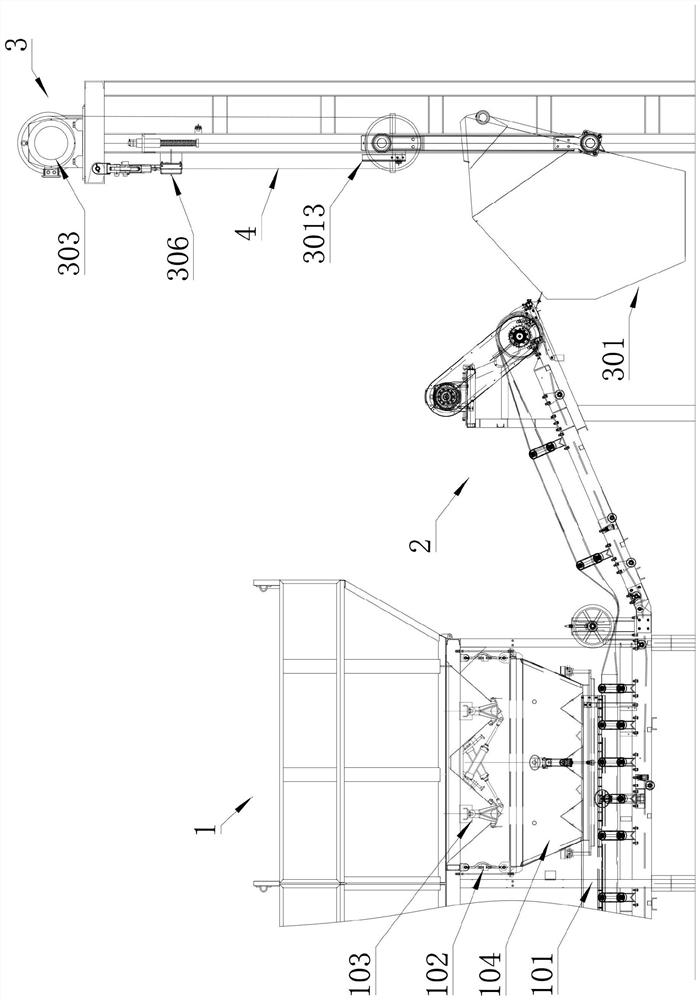

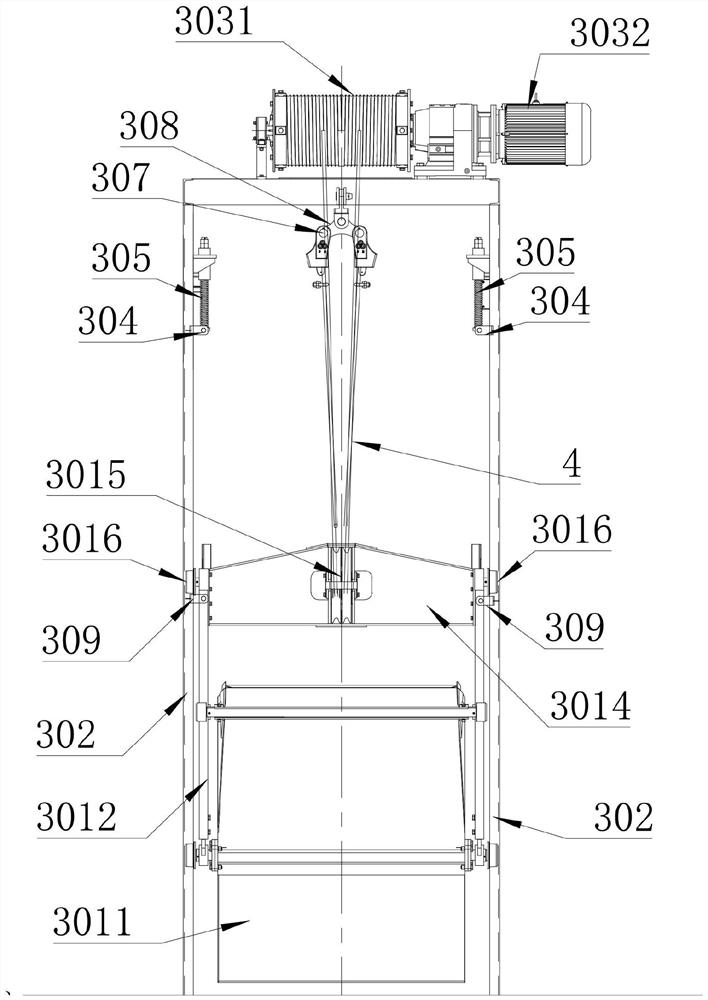

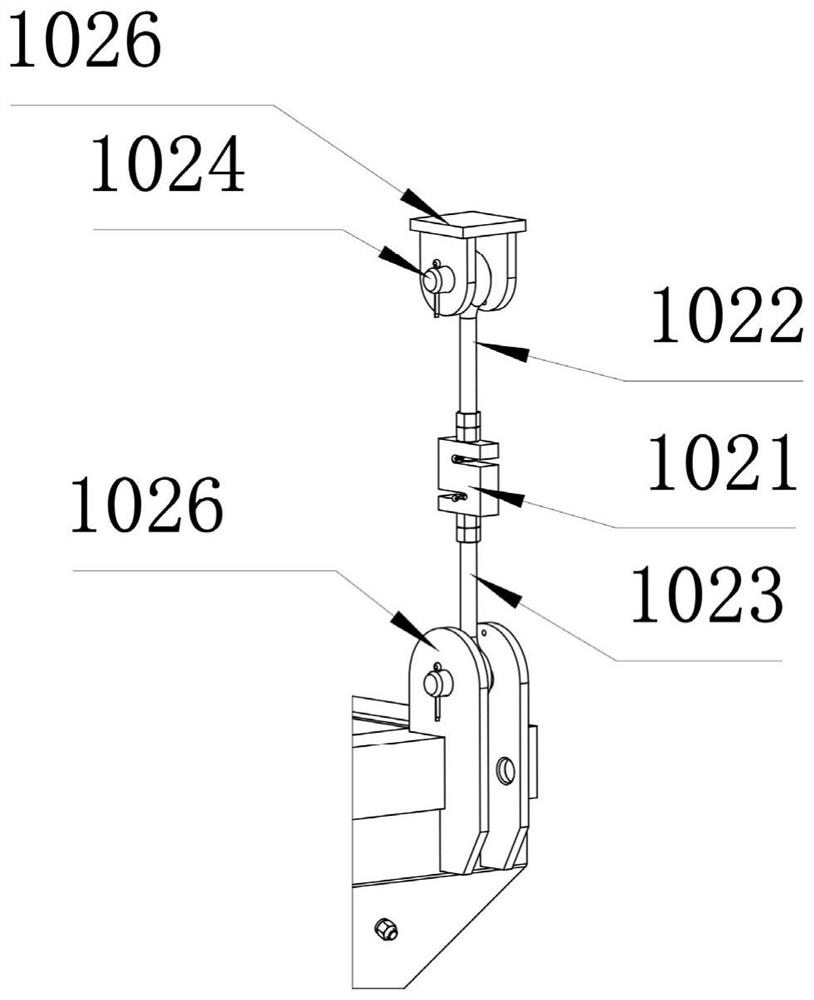

[0034] Such as Figure 1 to Figure 4As shown, in the first embodiment, the present invention provides an aggregate lifting system of a bucket elevator mixing plant, including a control system, an aggregate batching system 1, a conveying system 2 and an aggregate lifting system 3, and the conveying system 2 The feed port of the aggregate batching system 1 is set below the discharge port of the aggregate batching system 1. When the conveying system 2 is unloading, the lifting bucket 301 of the aggregate lifting system 3 is located at the discharge port of the conveying system 2. Below, the control system is used to control the operation of the aggregate batching system 1, the conveying system 2 and the aggregate lifting system 3. The specific operation mode is that the aggregate batching system 1 mixes the aggregate according to a certain ratio After that, it is unloaded to the conveying system 2, and then transported to the lifting bucket 301 through the conveying system 2, and...

specific Embodiment 2

[0050] Such as Figure 1 to Figure 5 As shown, the present invention also discloses the second embodiment. In the second embodiment, the present invention discloses an aggregate lifting system of a bucket-lift mixing plant. On the basis of the first embodiment, the main body of the weighing bucket The inner wall of the weighing bucket is provided with a rubber lining 105 whose size is suitable for the inner wall of the weighing bucket main body. The bottom of the rubber lining 105 is connected to the weighing bucket main body through a hinge. The rubber lining 105 It is connected with the pulling device 106, and the pulling device 106 is used to pull the rubber lining 105 to vibrate. By using the characteristics that the rubber lining 105 is softer than carbon steel and less likely to stick to the aggregate than carbon steel, the output shaft of the cylinder is pulled The telescoping action pulls the rubber lining 105 to vibrate to realize the rapid falling off of the aggregat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com