Constraint sheet, gradient damping structure comprising same and preparation method

A damping structure and sheet technology, applied in the field of damping materials, can solve the problems of low damping performance of restraint damping materials, weak restraint effect of damping layer, easy failure of restraint effect, etc., and achieve the effect of improving damping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]Preparation of damping sheet: Preheat the mixer at 120°C for 10 minutes, cut 100 phr of butyl rubber into thin slices, put it into the mixer and crush it for 10 minutes, add 100 phr CaCO3 and 100 phr polyisobutylene to adjust the viscosity of the system;

[0043] Add 50, 100, 150, and 200 phr of petroleum resin to the above-mentioned butyl rubber, and knead at 120°C for 120 minutes to obtain damping sheet materials with different glass transition temperatures. ℃, 10MPa hot pressing for 5 minutes, and then cold pressing to room temperature under the same pressure to form damping sheets with different glass transition temperatures; respectively numbered IIR1, IIR2, IIR3, IIR4.

[0044] Among them, the glass transition temperature of IIR1 is -46.7°C; the damping peak value is 1.52, and the temperature corresponding to the damping peak value is 34.3°C.

[0045] IIR2 glass transition temperature -31.6°C; damping peak 1.59, the temperature corresponding to the damping peak is ...

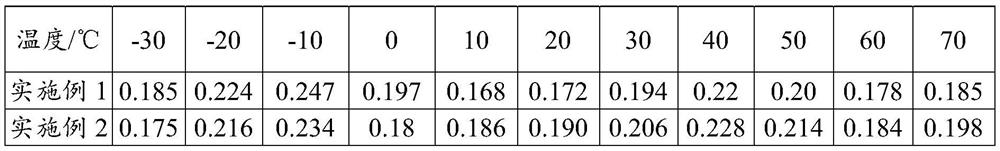

Embodiment 1-5

[0051] Table 1 shows the specific structure of the multi-layer damping material in Examples 1-5, wherein the serial number 1 indicates the layer close to the base steel, the serial number 2 is the second layer, and so on, and the unit of the thickness of each layer is mm.

[0052] The multi-layer constrained damping material of Table 1 Embodiment 1-5

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com